Are you struggling with drilling precise holes in various materials?

A step drill bit is designed for creating clean, accurate holes in metal and other materials, offering versatility and efficiency.

Keep reading to discover how step drill bits can enhance your drilling projects.

Advantages and Disadvantages of Step Drill Bits?

Are you unsure if step drill bits are the right choice for your projects?

Step drill bits provide multiple hole sizes in a single tool but may not be suitable for all materials.

Understanding the pros and cons can help you make an informed decision.

Advantages of Step Drill Bits

Step drill bits offer several benefits that make them a popular choice among professionals and DIY enthusiasts alike. One of the primary advantages is their versatility. A single step drill bit can create multiple hole sizes without the need to switch tools, saving time and effort. This is especially useful in projects where various hole diameters are required. Additionally, step drill bits are designed to reduce the risk of material deformation. Their stepped design ensures that holes are drilled cleanly and accurately, minimizing the chances of burrs or rough edges. This feature is particularly beneficial when working with thin or delicate materials, where precision is crucial.

Another significant advantage is the ease of use1. Step drill bits are typically easy to handle and require less pressure compared to traditional drill bits. This makes them suitable for both experienced users and beginners. The design also helps in dissipating heat more effectively, reducing the risk of overheating and extending the lifespan of the bit. Moreover, step drill bits are generally more durable and can withstand repeated use without significant wear, making them a cost-effective option in the long run.

Disadvantages of Step Drill Bits

While step drill bits offer numerous benefits, they also come with certain drawbacks that users should be aware of. One of the main disadvantages is their limited application range. Step drill bits are primarily designed for drilling through metal and similar materials. They may not perform as well on harder materials like concrete or masonry, where specialized drill bits are required. This limitation means that for projects involving a variety of materials, multiple types of drill bits may still be necessary.

Another drawback is the precision limitation. Although step drill bits provide multiple hole sizes, the increments between each step can be restrictive. Users seeking very specific hole diameters may find this limiting, as the step drill bit only offers predefined sizes. Additionally, step drill bits may not achieve the same level of precision as specialized bits designed for a single hole size. This can be a concern in applications where exact measurements are critical.

Furthermore, the stepped design, while advantageous for versatility, can sometimes lead to less efficient drilling in thicker materials. The transition between steps may cause slight inaccuracies or require more force, potentially affecting the overall quality of the hole. Lastly, step drill bits can be more expensive upfront compared to standard drill bits, which might be a consideration for those on a tight budget.

Drilling Thick Stainless with Step Drill?

Do you find drilling thick stainless steel challenging?

Step drill bits can effectively drill through thick stainless steel by providing controlled and precise drilling.

Learn the techniques to achieve the best results with step drill bits on stainless steel.

Techniques for Drilling Thick Stainless Steel with Step Drill Bits

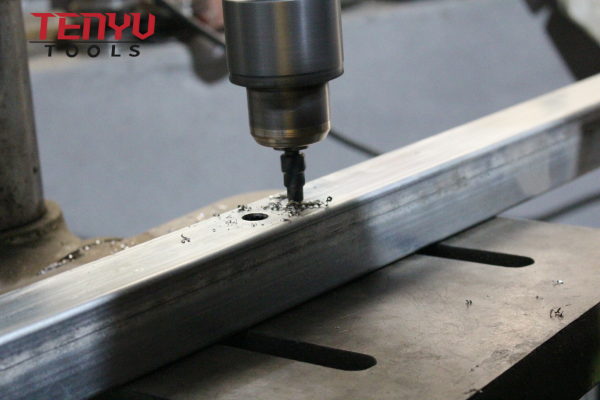

Drilling thick stainless steel requires the right tools and techniques to ensure clean, precise holes without damaging the material or the drill bit. Step drill bits are a suitable choice for this task due to their design, which allows for controlled drilling with multiple step sizes. To begin, select a step drill bit with an appropriate diameter for your project. Ensure that the bit is sharp and in good condition to facilitate smooth drilling through the tough stainless steel.

Before starting, mark the exact spot where the hole is needed to maintain accuracy. Secure the stainless steel firmly to prevent any movement during drilling, as even slight shifts can lead to inaccuracies or safety hazards. It’s essential to use a stable surface and apply steady, even pressure while drilling. Begin at the smallest step of the drill bit and gradually work your way up to the desired diameter. This step-by-step approach reduces the risk of overheating and prolongs the life of the drill bit.

Using a lubricant2, such as cutting oil, can significantly improve the drilling process. The lubricant helps to dissipate heat generated during drilling, reducing friction and preventing the stainless steel from hardening around the drill bit. This not only makes the drilling process smoother but also extends the lifespan of the step drill bit. Additionally, drilling at a slower speed allows for greater control and reduces the likelihood of material deformation or bit breakage.

Proper ventilation is crucial when drilling stainless steel, as the process can generate sparks and metal shavings. Wearing appropriate safety gear, including gloves and eye protection, is essential to protect against potential injuries. After drilling, deburr the hole to remove any sharp edges or rough spots, ensuring a clean and professional finish. By following these techniques, you can effectively use step drill bits to drill thick stainless steel with precision and efficiency.

Best Step Drill Bits Review in 2025?

Looking for the top step drill bits to use in your projects this year?

Our 2025 review highlights the best step drill bits based on quality, performance, and value for money.

Discover which step drill bits stand out in the market this year.

Top Step Drill Bits of 2025

In 2025, the market for step drill bits has seen significant advancements, offering a range of options tailored to different needs and budgets. Among the top contenders, the Tenyu Precision Step Drill Bit3 stands out for its exceptional quality and performance. Manufactured with high-grade steel, it ensures durability and longevity, making it a reliable choice for both professional and DIY projects. The Tenyu bit features a multi-step design that allows for precise drilling through various materials, including stainless steel, aluminum, and plastic. Its sharp cutting edges reduce the effort required, providing clean and accurate holes with minimal wear on the bit.

Another notable option is the DeWalt Titanium Step Drill Bit. Known for its robust construction, this bit is coated with titanium, enhancing its hardness and resistance to corrosion. The DeWalt bit is particularly favored for its ability to drill through thick metals without losing its sharpness, making it ideal for heavy-duty applications. Its ergonomic design ensures ease of handling, allowing users to maintain control and precision during drilling. Additionally, the bit’s versatility in handling multiple hole sizes eliminates the need for multiple tools, offering excellent value for money.

For those seeking a budget-friendly yet reliable option, the Bosch General Purpose Step Drill Bit is an excellent choice. Bosch has a reputation for producing high-quality tools, and their step drill bit is no exception. It offers a balanced combination of performance and affordability, making it suitable for a wide range of projects. The Bosch bit’s design ensures smooth drilling with minimal vibration, reducing the risk of material deformation. Its compatibility with various drill types adds to its versatility, making it a staple in both professional workshops and home toolkits.

Comparative Table of Top Step Drill Bits

| Brand & Model | Material | Coating | Best For | Price Range |

|---|---|---|---|---|

| Tenyu Precision Step Drill Bit | High-grade Steel | None | Precision drilling in metals | $$ |

| DeWalt Titanium Step Drill Bit | High-grade Steel | Titanium | Heavy-duty drilling in metals | $$$ |

| Bosch General Purpose Step Drill Bit | High-grade Steel | None | Versatile drilling tasks | $ |

| Irwin Multi-Material Step Drill Bit | High-grade Steel | Black Oxide | General-purpose drilling | $$ |

| Milwaukee Step Drill Bit | High-speed Steel | Titanium | Professional metalworking | $$$ |

This table highlights the key features and price ranges of some of the best step drill bits available in 2025. When choosing the right step drill bit, consider factors such as the material you’ll be working with, the bit’s durability, and your budget to select the option that best meets your needs.

How To Use A Step Drill Bit On Metal: Tools And Techniques?

Want to master using a step drill bit on metal effectively?

Using a step drill bit on metal involves selecting the right tools and applying proper techniques for clean, precise holes.

Learn the essential tools and methods for successful metal drilling with step bits.

Essential Tools for Using Step Drill Bits on Metal

To effectively use a step drill bit on metal, having the right tools is crucial. First and foremost, a reliable power drill is necessary, preferably one with adjustable speed settings. This allows for better control over the drilling process, ensuring that the step drill bit operates at optimal speeds for different metal types. Additionally, a drill press4 can provide greater stability and precision, especially for repetitive or high-precision drilling tasks.

Safety equipment is also essential when drilling metal. High-quality safety glasses protect your eyes from metal shavings and debris, while gloves safeguard your hands from sharp edges and potential burns. A sturdy workbench or drilling surface helps secure the metal piece, preventing movement that could lead to inaccurate holes or accidents. Using a clamp or vice to hold the metal firmly in place ensures stability and precision during drilling.

Lubricants, such as cutting oil or WD-40, play a vital role in the drilling process. Applying lubricant to the step drill bit and the metal surface reduces friction, helping to prevent overheating and prolonging the life of the drill bit. It also aids in achieving smoother drilling by minimizing resistance, allowing the bit to glide more easily through the metal. A cleaning brush or cloth is useful for removing metal shavings and excess lubricant, maintaining a clean working area.

Step-by-Step Techniques for Drilling Metal with Step Drill Bits

Begin by selecting the appropriate step drill bit for your metal type and desired hole size. Ensure that the bit is sharp and in good condition to facilitate smooth drilling. Mark the exact location where the hole is needed using a center punch or marker to guide the drilling process accurately. Secure the metal piece firmly to your workbench using clamps or a vice to prevent any movement during drilling.

Set your power drill to a low speed to start, allowing for better control and reducing the risk of overheating the bit. Apply a few drops of lubricant to the marked spot and the tip of the drill bit to ease the drilling process. Position the drill bit perpendicular to the metal surface and begin drilling with steady, even pressure. Let the drill bit do the work, avoiding excessive force that could cause the bit to bind or break.

As you drill, periodically retract the bit to clear out metal shavings and reapply lubricant if necessary. This helps maintain efficiency and prevents the bit from becoming clogged or overheated. Gradually increase the drill speed as the bit penetrates deeper into the metal, ensuring a consistent and clean hole. Once the desired hole size is achieved, carefully remove the drill bit and deburr the edges using a file or deburring tool to eliminate any sharp edges.

Maintaining the step drill bit is essential for continued performance. After use, clean the bit thoroughly to remove any residual metal shavings or lubricant. Store it in a dry, safe place to prevent rust and damage. Regular maintenance, such as sharpening the cutting edges, can extend the life of the step drill bit and ensure it remains effective for future projects. By following these techniques, you can achieve precise and clean holes in metal using step drill bits.

Drill Thin Metal Using Step Drills?

Struggling to drill thin metal without causing damage?

Step drills are ideal for drilling thin metal, providing control and minimizing the risk of tearing or warping the material.

Explore the best practices for drilling thin metal with step drill bits to achieve flawless results.

Best Practices for Drilling Thin Metal with Step Drill Bits

Drilling thin metal requires a delicate touch and the right tools to prevent deformation or tearing. Step drill bits are particularly well-suited for this task due to their stepped design, which allows for gradual drilling without exerting excessive force on the material. To begin, choose a step drill bit that matches the thickness and type of metal you are working with. A smaller step size can offer more control, reducing the risk of accidentally enlarging the hole beyond the desired size.

Securing the thin metal firmly is essential to maintain stability during drilling. Use clamps or a vice with protective padding to hold the metal in place without causing dents or marks. Placing a backing board beneath the metal can provide additional support and prevent the material from bending or warping under the pressure of the drill. Mark the exact spot for the hole using a center punch to create a small indentation, ensuring the drill bit starts at the correct location.

When drilling, start at a low speed to maintain control and prevent the drill bit from slipping. Apply gentle, consistent pressure, allowing the step drill bit to gradually enlarge the hole through each step. Avoid forcing the bit, as this can cause the thin metal to stretch or tear. If necessary, use a lubricant5 to reduce friction and facilitate smoother drilling, especially when working with harder metals like stainless steel.

Monitoring the drilling process closely is crucial when working with thin metal. Stop periodically to check the progress and ensure the hole is forming correctly. If the drill bit begins to bind or the metal shows signs of distortion, retract the bit and adjust your technique accordingly. Once the hole reaches the desired size, carefully remove the drill bit and deburr the edges to eliminate any sharp or rough areas. Following these best practices will help you achieve clean, precise holes in thin metal using step drill bits.

Using Step Drills for Chassis Holes?

Need to create precise holes in vehicle chassis or similar structures?

Step drills offer the accuracy and strength needed for drilling chassis holes, ensuring secure and reliable fittings.

Learn how to effectively use step drill bits for chassis applications to enhance your projects.

Techniques for Drilling Chassis Holes with Step Drill Bits

Drilling holes in vehicle chassis requires precision and durability, as these holes often serve as anchor points for various components. Step drill bits are an excellent choice for this application due to their ability to create accurate, clean holes in thick metal structures. To begin, select a step drill bit that matches the required hole size for your chassis components. Ensure the bit is made from high-quality, hardened steel to withstand the demands of drilling through robust materials like steel or aluminum.

Preparing the chassis is a critical step in achieving precise holes. Clean the drilling area thoroughly to remove any dirt, grease, or debris that could interfere with the drilling process. Mark the exact location of each hole using a center punch6 to create a small indentation, guiding the drill bit accurately. Secure the chassis firmly using clamps or a vice, ensuring that it remains stable throughout the drilling process. A backing board can provide additional support and prevent the metal from deforming or moving under the drill’s pressure.

When drilling, use a power drill with adjustable speed settings to maintain control over the process. Start at a low speed to establish a steady drilling path, gradually increasing the speed as the bit penetrates deeper into the chassis material. Apply even, consistent pressure, allowing the step drill bit to work through each step without forcing it, which could cause the bit to bind or the metal to warp. Periodically retract the bit to clear away metal shavings and reapply lubricant if necessary, ensuring smooth and efficient drilling.

Maintaining accuracy is essential when drilling chassis holes, as even slight deviations can affect the alignment and stability of mounted components. Take your time to guide the drill bit accurately, avoiding rapid or jerky movements that could lead to misalignment. After drilling, inspect each hole for any imperfections or sharp edges. Use a deburring tool or file to smooth out the edges, ensuring a clean and professional finish that facilitates secure fittings. Properly drilled chassis holes contribute to the overall strength and reliability of the vehicle structure, making step drill bits a valuable tool for automotive projects.

Conclusion

Step drill bits are versatile tools that enhance drilling efficiency and precision.

-

"Ease of use" highlights how step drill bits are user-friendly, making them ideal for both beginners and professionals. ↩

-

Lubricants such as cutting oil play a crucial role in reducing heat and friction while drilling stainless steel. ↩

-

The keyword “step drill bits” represents a broad category and deserves an external link to provide further details about the product, its uses, and advancements in the market. ↩

-

A drill press can provide greater precision and stability during metal drilling. ↩

-

Lubricants are important when drilling through harder materials like stainless steel. ↩

-

The center punch is an essential tool for marking drill points accurately, which is vital for the precision described in the article. ↩