How to Cut Melamine on a Table Saw?

Cutting melamine can be frustrating. Chips and rough edges often ruin projects. But with the right techniques, you can achieve clean cuts every time.

Using a table saw with the proper blade and technique ensures smooth, precise cuts on melamine surfaces.

Keep reading to discover the best practices and tools for cutting melamine effectively.

What is the Best Saw Blade for Cutting Melamine?

Struggling with jagged melamine cuts? Choosing the right blade is crucial to avoid messy edges.

A high-quality, carbide-tipped blade with a high tooth count is ideal for cutting melamine cleanly.

Understanding the best saw blade can make your melamine cutting projects seamless and professional.

Choosing the Right Blade

When selecting a saw blade for melamine, look for blades with:

- High Tooth Count1: Blades with 80 teeth or more provide smoother cuts, reducing chipping.

- Carbide Tips: These ensure durability and maintain sharpness longer.

- Thin Kerf: Reduces waste and requires less power from the saw.

Blade Types Comparison

| Blade Type | Tooth Count | Ideal Use | Pros | Cons |

|---|---|---|---|---|

| Plywood Blade | 60-80 | Melamine, Plywood | Smooth cuts, less splintering | More expensive |

| General Purpose Blade | 24-40 | Versatile woodworking | Affordable, widely available | More chipping on melamine |

| Fine Finish Blade | 80-100 | Detailed work, Melamine | Very smooth cuts, minimal splintering | Slower cutting speed |

Installation Tips

- Proper Alignment: Ensure the blade is aligned correctly to the fence and miter slots to prevent binding.

- Blade Height: Set the blade height just above the melamine thickness to minimize chipping.

- Secure the Material: Use clamps to hold the melamine firmly against the fence and table.

Choosing the right blade not only improves cut quality but also enhances safety and efficiency in your projects. Investing in a quality blade tailored for melamine can save time and reduce material waste.

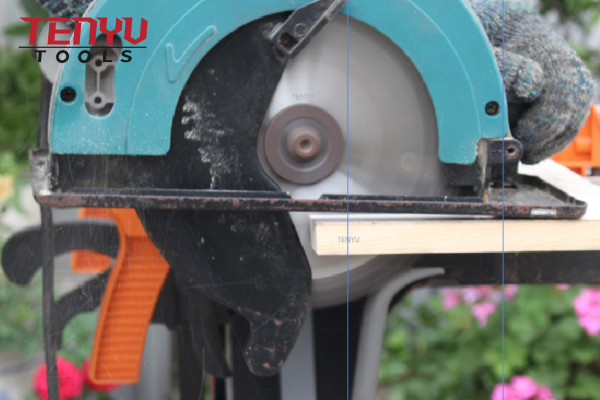

How to Cut Melamine with a Circular Saw?

Frustrated with uneven melamine cuts using a circular saw? Precision is key to a flawless finish.

Using a circular saw with the proper blade and techniques can achieve clean melamine cuts similar to a table saw.

Let’s explore how to effectively cut melamine using a circular saw, ensuring smooth and accurate results.

Preparing Your Tools and Workspace

Before you start, ensure you have:

- Appropriate Blade: A fine-tooth carbide-tipped blade specifically for melamine.

- Straight Edge or Guide: To maintain a straight cut line.

- Clamps: To secure the melamine sheet firmly.

- Safety Gear2: Goggles and ear protection for safe operation.

Step-by-Step Cutting Process

- Measure and Mark: Accurately measure where you need to cut and mark the line with a pencil.

- Secure the Melamine: Clamp the sheet to your workbench or use a saw guide to prevent movement during cutting.

- Set the Blade Depth: Adjust the blade so it protrudes just slightly above the melamine surface.

- Make the Cut: Slowly guide the circular saw along the marked line, maintaining steady pressure to avoid chipping.

- Finishing Touches: If any rough edges remain, lightly sand them for a smooth finish.

Tips for Clean Cuts

- Use a Sacrificial Board: Place an extra board beneath the melamine to support the material and reduce chipping.

- Cut Slowly: Rushing can lead to uneven cuts and increased chances of splintering.

- Blade Speed: Use a slower blade speed to enhance control and reduce heat buildup, which can affect the cut quality.

Common Mistakes to Avoid

- Dull Blades: A dull blade increases the risk of chipping and makes cutting more difficult.

- Improper Support: Insufficient support can cause the melamine to flex, leading to inaccurate cuts.

- Ignoring Safety: Always prioritize safety by wearing appropriate gear and following tool guidelines.

By following these steps and tips, you can achieve professional-quality melamine cuts with your circular saw, enhancing the overall look and functionality of your projects.

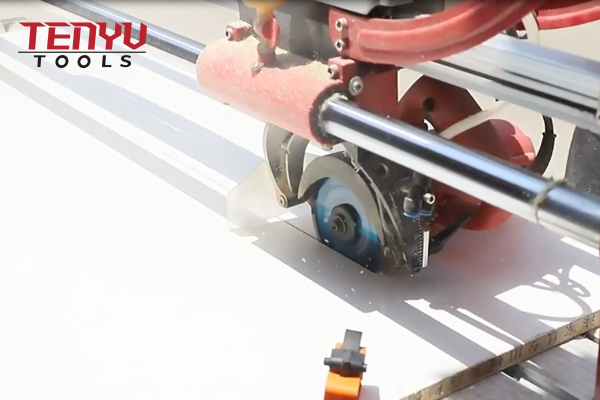

7 1/4 Circular Saw Blade for Melamine?

Not sure if a 7 1/4" circular saw blade is suitable for melamine? Size matters for precision.

A 7 1/4" circular saw blade can effectively cut melamine when paired with the right blade type and technique.

Let’s delve into why this blade size works and how to maximize its performance for melamine cutting.

Advantages of a 7 1/4" Blade

- Versatility: Commonly available, suitable for various cutting tasks beyond melamine.

- Power: Provides enough power and stability for precise cuts on melamine sheets.

- Compatibility: Fits most standard circular saws3, making it a convenient choice.

Selecting the Right 7 1/4" Blade for Melamine

When choosing a 7 1/4" blade for melamine, consider:

- Tooth Count: Opt for a higher tooth count (60-80) to ensure smooth cuts.

- Carbide-Tipped Teeth: These maintain sharpness and resist wear from melamine’s abrasive surface.

- Blade Material: Ensure the blade is designed for fine woodworking to minimize splintering.

Installation and Setup

- Blade Installation: Follow the manufacturer’s instructions to securely install the blade, ensuring it is properly tensioned.

- Adjusting the Guard: Set the blade guard to the correct height to expose only the necessary part of the blade for cutting.

- Blade Alignment: Ensure the blade is perpendicular to the saw base for accurate, straight cuts.

Performance Tips

- Cutting Speed: Maintain a consistent, moderate speed to reduce the risk of chipping.

- Support the Material: Use additional support to keep the melamine flat and prevent vibration during cutting.

- Multiple Passes: For thicker melamine, make multiple shallow passes instead of trying to cut through in one go.

Maintenance for Longevity

- Regular Cleaning: Remove resin and debris from the blade after each use to maintain efficiency.

- Blade Sharpening: Periodically check and sharpen the blade to ensure optimal cutting performance.

- Proper Storage: Store the blade in a dry, safe place to prevent damage and rust.

Using a 7 1/4" circular saw blade correctly can provide excellent results when cutting melamine, combining versatility with precision to meet your project needs.

Cutting Melamine without Chipping?

Tired of melamine edges splintering? Chipping can ruin the look of your projects.

Implementing the right techniques and tools can help you cut melamine without chipping, ensuring clean and professional edges.

Here’s how to achieve flawless melamine cuts every time.

Choosing the Right Blade

As previously discussed, a high-tooth-count4, carbide-tipped blade is essential. This reduces the chance of chipping by providing smoother cuts.

Proper Material Support

Ensuring that the melamine is well-supported prevents movement during cutting, which can lead to splintering. Use sturdy clamps and a stable work surface.

Cutting Techniques

- Slow and Steady: Cutting too quickly increases the risk of chipping. Maintain a steady pace.

- Use a Sacrificial Board: Placing a scrap piece beneath the melamine helps support the material and minimize splintering.

- Score the Cut Line: Lightly scoring the melamine with a utility knife along the cut line can help guide the saw and reduce chipping.

Blade Settings

- Blade Depth: Adjust the blade so it only extends slightly above the melamine surface. This minimizes the blade’s exposure and reduces chipping.

- Blade Angle: Ensure the blade is perpendicular to the work surface to maintain a straight cut.

Finishing Touches

After cutting, use fine-grit sandpaper or a sanding block to smooth any minor imperfections. This step ensures that your melamine edges are clean and ready for assembly or finishing.

Additional Tips

- Use Painter’s Tape: Applying tape along the cut line can help hold the melamine in place and reduce splintering.

- Dust Control: Keeping the cutting area free of dust and debris ensures a cleaner cut and better blade performance.

- Practice First: If you’re new to cutting melamine, practice on scrap pieces to get a feel for the blade and saw settings.

Common Mistakes to Avoid

- Dull Blades: A dull blade increases the likelihood of chipping. Always use a sharp, high-quality blade.

- Insufficient Support: Failing to secure the melamine properly can cause vibrations and uneven cuts.

- Incorrect Blade Height: Setting the blade too high can lead to excessive chipping and poor cut quality.

By following these strategies, you can significantly reduce chipping when cutting melamine, resulting in professional-looking projects with clean, precise edges.

Conclusion

Cutting melamine cleanly is achievable with the right tools and techniques. Master these methods for flawless results every time.

-

High tooth count is crucial for providing smoother cuts, which is important when working with materials like melamine that tend to chip easily. ↩

-

Safety is paramount when operating power tools, and this keyword directly relates to user protection. ↩

-

This link will be useful to explain the compatibility of circular saws with various blade types. ↩

-

The term “high-tooth-count” refers to a specific characteristic of blades that influences cut quality. ↩