How to Cut Laminate Countertops?

Are you struggling to cut laminate countertops without making a mess?

Cutting laminate countertops requires the right tools and techniques to ensure a clean and precise finish.

Don’t worry, I’ve got you covered with all the information you need to tackle this project confidently.

What is the Best Saw for Cutting Laminate Flooring?

Are you unsure which saw to use for cutting laminate flooring effectively?

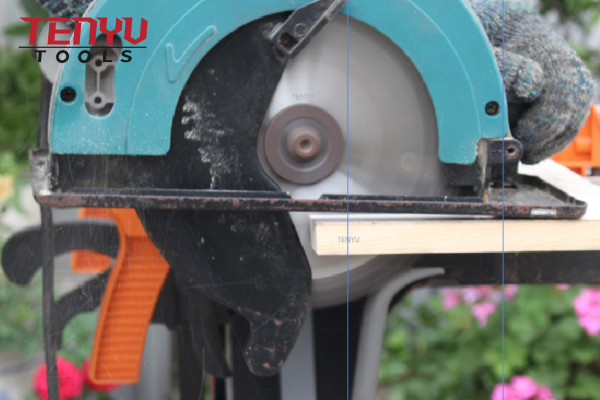

The best saw for cutting laminate flooring is a circular saw equipped with a fine-tooth blade, ensuring smooth and accurate cuts.

Choosing the right saw can make all the difference in achieving professional-looking results.

Understanding Saw Types

When it comes to cutting laminate flooring1, not all saws are created equal. Circular saws are generally the preferred choice due to their versatility and precision. They allow for straight and angled cuts, which are essential for fitting countertops perfectly.

Circular Saw Advantages

- Precision: Circular saws offer accurate cuts with minimal effort.

- Versatility: They can handle various materials, not just laminate.

- Portability: Lightweight and easy to maneuver around your workspace.

Selecting the Right Blade

The blade you choose plays a crucial role in the quality of your cuts. A fine-tooth blade is essential for laminate flooring to prevent chipping and ensure a smooth finish.

| Blade Type | Teeth Count | Best For |

|---|---|---|

| Fine-tooth Blade | 60-80 | Laminates and veneers |

| Wood Circular Blade | 40-60 | General-purpose wood cutting |

| Carbide-Tipped Blade | 40-60 | Particle board and plywood |

Safety First

Always prioritize safety when using power tools. Wear protective eyewear and gloves, and ensure your workspace is well-ventilated. Secure the laminate firmly to prevent slipping during the cutting process.

Personal Tip

When I first started cutting laminate countertops, I struggled with achieving clean edges. Investing in a high-quality circular saw and practicing on scrap pieces made a significant difference in my results.

Best Circular Saw Blade for Particle Board?

Are you confused about which circular saw blade works best for particle board?

For cutting particle board, a carbide-tipped circular saw blade with 40-60 teeth provides the best balance between speed and finish quality.

Using the right blade ensures efficient cutting and reduces the risk of damaging the material.

Why Carbide-Tipped Blades?

Carbide-tipped blades2 are durable and maintain sharpness longer than steel blades. This makes them ideal for cutting particle board, which can be tough on blades.

Benefits of Carbide-Tipped Blades

- Durability: Lasts longer under heavy use.

- Precision: Maintains a sharp edge for cleaner cuts.

- Versatility: Suitable for various materials, including wood and composite boards.

Teeth Count Matters

The number of teeth on a blade affects the cutting performance. For particle board, a blade with 40-60 teeth is optimal. Fewer teeth allow for faster cuts, while more teeth provide a smoother finish.

| Blade Type | Teeth Count | Suitable For |

|---|---|---|

| 40-60 Teeth | 40-60 | Particle board and plywood |

| 80-100 Teeth | 80-100 | Smooth finishes on finer materials |

| Variable Tooth Count | Varies | Specialized cutting needs |

Cutting Technique

Proper cutting technique is essential to avoid splintering. Use a guide or straight edge to ensure straight cuts. Feed the blade steadily without forcing it through the material to maintain control and accuracy.

Personal Experience

I remember cutting my first particle board countertop and noticing how quickly the blade dulled. Switching to a carbide-tipped blade extended the life of my tools and improved the quality of my work.

Are All Circular Saw Blades the Same?

Do you think all circular saw blades perform identically?

No, circular saw blades vary in design, tooth count, and materials, affecting their performance and suitability for different tasks.

Understanding these differences helps you choose the right blade for each project.

Blade Design Variations

Circular saw blades come in various designs tailored to specific cutting needs. Some blades are designed for smooth finishes3, while others prioritize cutting speed and efficiency.

Types of Blade Designs

- Rip Blades: Designed for cutting along the grain of wood.

- Crosscut Blades: Ideal for cutting across the grain, providing smoother edges.

- Combination Blades: Versatile for both rip and crosscuts.

- Specialty Blades: Made for specific materials like metal or masonry.

Material Composition

The material of the blade affects its durability and cutting performance. Common materials include:

- Steel: Basic blades suitable for light-duty tasks.

- Carbide-Tipped: Enhanced durability for heavy-duty and frequent use.

- Wood Circular Blades: Specifically designed for cutting wood with precision.

Tooth Configuration

The arrangement and shape of the teeth impact the cutting action. Blades with alternate top bevel (ATB) teeth provide cleaner cuts, while flat top grind (FTG) blades are better for ripping.

| Blade Feature | Impact on Performance |

|---|---|

| Tooth Count | Higher count = smoother cuts |

| Tooth Shape | ATB = cleaner edges, FTG = faster cuts |

| Material | Carbide-tipped = longer-lasting, wood circular = optimized for wood cutting |

Choosing the Right Blade

Selecting the right blade depends on the material you’re cutting and the finish you desire. Always match the blade type to your specific project needs to achieve the best results.

My Takeaway

I’ve experimented with various blades over the years and found that understanding their differences allows me to switch blades based on the project, saving time and improving quality.

What Circular Saw Blade Should I Buy?

Are you overwhelmed by the options when choosing a circular saw blade?

The best circular saw blade for your needs depends on the material you’re cutting and the desired finish, with carbide-tipped blades being a versatile choice for most projects.

Making an informed choice ensures you get the best performance and longevity from your tools.

Assessing Your Needs

Before purchasing a blade, consider the types of materials4 you frequently work with. This will help narrow down the options and ensure you select a blade that meets your specific requirements.

Common Material Needs

- Wood: Wood circular blades with 40-60 teeth for clean and precise cuts.

- Metal: Specialized metal-cutting blades with finer teeth.

- Masonry: Diamond-coated blades for cutting stone or concrete.

Budget Considerations

Quality blades can be an investment, but they often pay off in durability and performance. While cheaper blades may seem appealing, they can wear out quickly and result in poorer cut quality.

| Blade Type | Price Range | Durability | Best For |

|---|---|---|---|

| Steel Blades | Low | Low | Light-duty tasks |

| Wood Circular Blades | Medium | High | General-purpose and wood cutting |

| Carbide-Tipped Blades | Medium | High | General-purpose and heavy use |

| Diamond-Coated Blades | High | Very High | Cutting hard materials |

Brand Reputation

Opt for reputable brands known for quality and reliability. Brands like DeWalt, Bosch, and Makita offer a range of blades that are trusted by professionals and DIY enthusiasts alike.

Versatility and Customization

Consider blades that offer versatility for multiple projects. Additionally, some blades allow for customization, such as adjustable settings for different cutting depths or angles.

Personal Recommendation

When I needed a reliable blade for various projects, I chose a carbide-tipped blade from a trusted brand. It provided excellent performance across different materials and has lasted much longer than cheaper alternatives.

Conclusion

Cutting laminate countertops is easier with the right tools and knowledge.

-

Laminate flooring is a common material, and adding a link here helps provide readers with more information on the types, benefits, and applications of laminate flooring. ↩

-

Linking to this keyword helps highlight the advantage of carbide-tipped blades in terms of durability and longevity. ↩

-

This keyword refers to a specific feature of circular saw blades and linking it will guide users to resources that explain which blades are best for achieving smooth, clean cuts. ↩

-

Adding a link to this keyword will provide the reader with more detailed information on various types of blades available in the market, especially those suited for different materials. ↩