What are the Best Circular Saw Blades in 2025 in India?

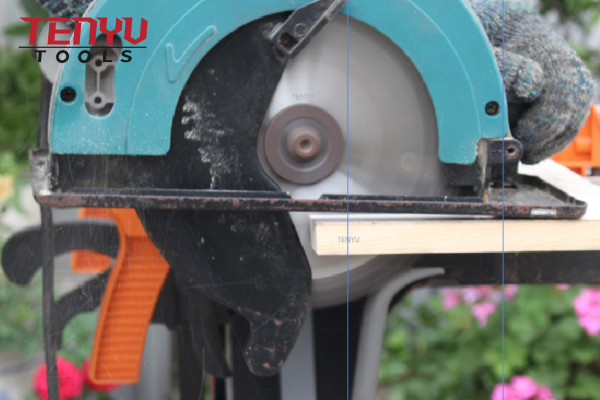

Circular saw blades are essential tools for anyone working with wood, metal, or even plastic. As 2025 approaches, it’s critical to choose the right saw blades to ensure clean cuts, efficiency, and durability. But with so many choices available in India, how do you decide which blade is best for your needs?

Circular saw blades vary widely based on the material you are cutting, the type of cut you need, and the blade’s overall quality. This guide will help you navigate through the best options available in 2025, especially highlighting Tenyu Tools’ high-quality saw blades.

Whether you’re a professional contractor or a DIY enthusiast, selecting the right circular saw blade is crucial. In this article, we’ll explore the best circular saw blades for wood, smooth cuts, tearout prevention, and durability, with a particular focus on the superior options from Tenyu Tools.

What is the Best Blade to Cut Wood?

Cutting wood requires a specific type of blade that can handle the material’s density and grain structure. Choosing the right blade will help you achieve clean, precise cuts while extending the lifespan of your saw.

A blade designed specifically for cutting wood usually has a higher number of teeth, which results in smoother, more accurate cuts. Wood blades also have a lower tooth angle to reduce splintering and tearout. Tenyu Tools offers blades that excel in these areas, ensuring both quality and longevity.

Dive deeper Paragraph:

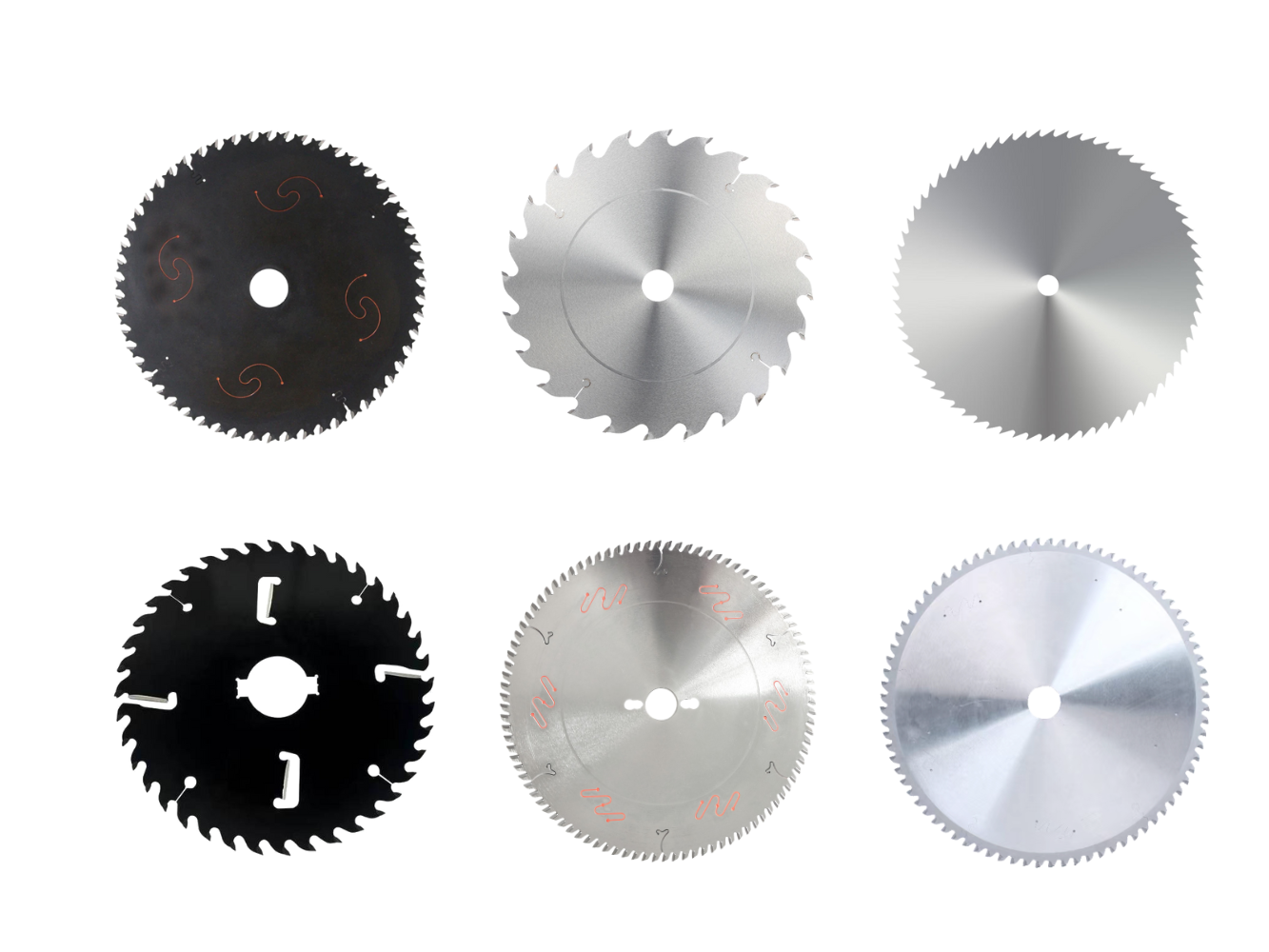

When cutting wood, the number of teeth on your blade plays a vital role. A blade with fewer teeth (24 to 40 teeth) is better suited for quick, rough cuts, whereas a blade with more teeth (60 to 80 teeth) is ideal for fine, smooth cuts. The material of the blade is another important factor; carbide-tipped blades are highly recommended for cutting through hardwoods as they stay sharp longer and cut more efficiently.

Tenyu Tools’ carbide-tipped1 circular saw blades are particularly known for their durability and precision when cutting wood. The carbide material resists wear and tear, providing you with a clean cut even after extended use. These blades are designed to handle both softwood and hardwood with ease, ensuring minimal effort and high efficiency in every cut.

In addition to the number of teeth, the blade’s tooth geometry matters. Blades with an alternate top bevel (ATB) design are great for clean cuts in softwoods, while a triple-chip grind (TCG) is more suited for harder woods. Tenyu’s offerings feature advanced tooth geometries to optimize cutting performance, allowing users to work with a variety of wood types.

For cutting through treated woods or materials like MDF or plywood, Tenyu’s precision crosscut saw blades offer the ideal solution. Their fine teeth help minimize splintering, ensuring you get the best finish every time.

Which Saw Blades Make the Smoothest Cut?

When you need a smooth, clean cut, it’s crucial to use a saw blade designed for precision. Smooth cuts not only make the finished product look professional, but they also reduce the need for additional sanding or finishing work.

The smoothest cuts come from blades with a higher number of teeth and those designed for specific materials like plywood or MDF. Tenyu Tools is known for providing blades that offer exceptional smooth cuts, even under heavy-duty conditions.

Dive deeper Paragraph:

Smooth cuts require blades that minimize vibration, heat, and friction. The more teeth a blade has, the finer the cut will be. Typically, saw blades with 60 to 80 teeth provide the smoothest cuts, especially for materials like plywood and MDF. These blades are designed with very thin kerfs to reduce resistance and prevent the material from splintering or chipping.

Tenyu Tools’ carbide-tipped blades are particularly excellent at providing smooth cuts. The advanced coating and precise tooth configuration of Tenyu saw blades ensure minimal heat buildup, which is vital when working with materials that are prone to chipping. These blades not only stay sharp for longer periods but also allow for smooth, efficient cutting, reducing the need for additional finishing work.

Blade material is another key factor. Carbide-tipped blades are a preferred choice because they are more durable, cutting through wood and other materials with higher efficiency. Tenyu’s blades are made with the highest quality carbide materials, which means you can rely on them for smooth cuts even after many uses.

One of the standout products from Tenyu Tools is the Tenyu 80-tooth carbide saw blade2, which is designed to minimize vibration and produce ultra-smooth cuts in both hardwoods and plywood. This blade is particularly effective when you need a clean, precise finish in your woodworking projects.

Additionally, if you are cutting thin sheets of material, Tenyu’s Precision Trim blade provides an ultra-smooth cutting experience, ensuring no chipping or tearing on edges.

What is the Best Saw Blade to Prevent Tearout?

Tearout is a common issue when cutting through materials like plywood or MDF, but it can be minimized by choosing the right blade. Preventing tearout ensures that your cuts are clean and professional, without the frustration of needing to fix the edges afterward.

The key to preventing tearout lies in the blade’s tooth design and its material construction. Tenyu Tools has developed blades specifically designed to tackle this issue.

Dive deeper Paragraph:

Blades designed to prevent tearout typically feature a higher tooth count, often 80 to 100 teeth, which creates a finer cut with less pressure exerted on the material. Additionally, the use of Triple Chip Grind (TCG)3 teeth is crucial in preventing tearout. TCG blades alternate between flat and beveled teeth, which help in creating a clean cut while also distributing the cutting pressure more evenly across the material.

Tenyu Tools’ specialized anti-tearout blades feature this exact tooth design, providing clean, chip-free cuts in a variety of materials. Their precision-engineered blades make them ideal for cutting delicate materials like plywood, MDF, and veneer, where tearout is often a concern.

Another key consideration is the coating on the blade. Anti-friction coatings help reduce heat and friction, which can sometimes contribute to tearout. Tenyu’s carbide-tipped blades feature an anti-friction coating that ensures smoother cuts and less chance of material damage during operation. These coatings also help in reducing the wear on the blade, giving it a longer lifespan.

If you need to cut through laminate or veneer, Tenyu’s negative rake blades can be an excellent choice. These blades have teeth that are angled backward, which results in less material removal during the cut, thus preventing the surface from chipping or tearing.

The Tenyu TCT Circular Saw Blade is widely regarded for its ability to minimize tearout in delicate wood and composite materials. With its advanced design and carbide tips, you’ll get the cleanest cuts possible, every time.

How Long do Circular Saw Blades Last?

Circular saw blades don’t last forever, but with proper maintenance and care, their lifespan can be extended significantly. How long a circular saw blade lasts depends on several factors, such as the material you’re cutting, the quality of the blade, and how often the blade is used.

Dive deeper Paragraph:

On average, a circular saw blade can last anywhere from 6 months to 2 years, depending on usage. If you’re using the blade daily for tough materials like hardwoods or metal, you might need to replace the blade sooner. However, if you’re cutting softer materials like MDF or plywood, the blade will last longer.

To extend the lifespan of your circular saw blade, it’s essential to maintain it properly. Regularly cleaning the blade and removing any pitch buildup will ensure that it stays sharp. If you notice that the blade is becoming dull, it’s time to either sharpen it or replace it.

Carbide-tipped blades tend to last the longest because the carbide material is highly resistant to wear. Additionally, Tenyu Tools’ carbide-tipped saw blades4 are engineered for durability, making them one of the most long-lasting blades available. With proper care, these blades can easily withstand heavy use and continue to deliver top-notch cutting performance.

When choosing a saw blade, consider its intended usage and material. If you need a blade that will perform reliably over time, investing in a premium carbide-tipped blade from Tenyu Tools is a smart choice. Although they are more expensive upfront, they offer long-term durability and superior cutting performance.

Conclusion

Choosing the right circular saw blade is crucial for achieving clean, smooth cuts and ensuring long-lasting performance. Tenyu Tools’ blades are the ideal choice for professionals looking for high-quality, durable, and efficient blades. Whether you’re cutting wood, preventing tearout, or extending blade life, Tenyu’s products are designed to meet your needs with exceptional performance and reliability.

-

Carbide-tipped blades are mentioned as ideal for cutting hardwoods due to their durability and efficiency. ↩

-

The 80-tooth saw blade from Tenyu is specifically mentioned as providing ultra-smooth cuts and is ideal for creating clean, precise finishes. ↩

-

TCG is a key technique in blade design, and linking to this term will provide readers with more technical understanding of how alternating flat. ↩

-

emphasizing the durability and performance advantages of their carbide-tipped saw blades. ↩