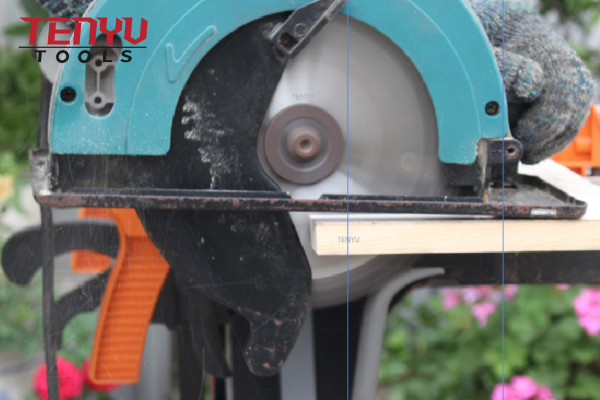

Can You Use Circular Saw Blade on Miter Saw?

A circular saw blade is a powerful tool in the hands of any DIYer or professional woodworker. But can it be used on a miter saw? This question often pops up when people are looking for ways to maximize their tools. In this article, we will dive into the details to help you understand the compatibility and differences between these two saws, and give you tips on how to use your circular saw blade effectively on a miter saw.

Yes, a circular saw blade can be used on a miter saw, but it is not always ideal. The blade’s teeth, material, and purpose must match the project you’re working on.

To get the best performance, it’s important to understand the various aspects that affect saw blade compatibility, like the teeth and blade material. Let’s break this down further so you can make the right choice for your next project.

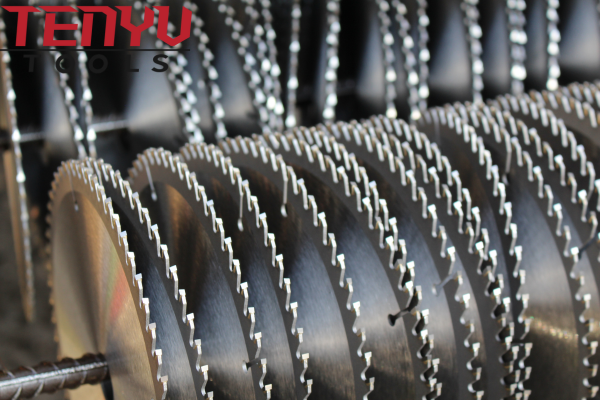

Circular Saw Blade Teeth Guide

Cutting with a saw blade is not just about having the right tool; the teeth of the blade play a crucial role. Understanding the different teeth types helps you select the best blade for the material you’re cutting.

Circular saw blades have different teeth configurations that suit different cutting applications. The teeth vary in size, shape, and material, affecting how cleanly and quickly the blade can cut through materials.

Types of Circular Saw Blade Teeth

- Flat Top Grind (FTG): The most common tooth type for general-purpose cutting. It is perfect for cutting through softwood.

- Alternate Top Bevel (ATB): Features teeth that alternate between a left and right bevel. This design is great for cutting plywood, melamine, and hardwood, providing a smooth edge.

- High Alternate Top Bevel (Hi-ATB): Similar to the ATB but with sharper angles. It’s ideal for fine cuts on plywood and melamine.

- Triple Chip Grind (TCG)1: Used for cutting hard materials like plastic or metal, this tooth type features alternating teeth with a flat surface followed by a steep angle.

Choosing the Right Teeth

When using a circular saw blade on a miter saw, it’s crucial to match the blade to the material. For example, a blade with ATB teeth is ideal for cutting plywood or melamine since it minimizes chip-out. A blade with a TCG or FTG configuration would work better for thicker, harder materials.

What is the Best Saw Blade for Cutting Melamine?

Melamine is a popular material for furniture and cabinetry, but it can be tricky to cut. If you want smooth, clean cuts without fraying or chipping, you need to choose the right saw blade.

The best saw blade for cutting melamine is one that minimizes chipping and produces a smooth edge. Typically, a blade with a high tooth count and an ATB or Hi-ATB tooth configuration will do the job. These types of blades help reduce the chances of the material splintering along the cut line.

Why ATB Blades Work for Melamine

The ATB (Alternate Top Bevel) configuration features teeth that alternate between a left and right bevel. This design reduces the impact of the blade on the material, producing cleaner, smoother cuts with less chipping. These blades are particularly useful when cutting laminate2 and melamine because they prevent fraying.

Additionally, using a finer tooth count, like 60 or 80 teeth, can give a cleaner finish on melamine, making the cut lines almost invisible. If you’re working on large panels of melamine, a table saw might be a better choice, but a miter saw with the right blade can still get the job done.

How to Cut Melamine with a Circular Saw?

Cutting melamine with a circular saw can be tricky, but with the right preparation and technique, it’s definitely doable.

To cut melamine smoothly with a circular saw, follow these steps to minimize chipping and ensure accuracy. Proper cutting techniques and using the right blade make all the difference when working with this tricky material.

Step-by-Step Guide for Cutting Melamine with a Circular Saw

- Choose the Right Blade: As mentioned earlier, opt for a blade with an ATB or Hi-ATB tooth configuration. A 60- or 80-tooth blade will give you the cleanest cut.

- Use Painter’s Tape3: Before cutting, apply painter’s tape along the cut line. This will help prevent chipping as the blade cuts through the melamine surface.

- Set the Depth of Cut: Adjust the circular saw so the blade only slightly exceeds the thickness of the melamine. This will reduce splintering on the underside.

- Support the Material: Use supports or clamps to hold the melamine sheet steady while cutting. This reduces vibration and gives you more control.

- Cut Slowly and Steadily: Don’t rush the cut. Allow the saw to move at its own pace and apply even pressure.

- Finish with Sandpaper: After cutting, you may need to lightly sand the edges to remove any remaining roughness.

Following these steps ensures that your cuts are clean and precise, even when using a circular saw on melamine.

How to Avoid Rust for a Wood Circular Saw Blade?

Rust on a circular saw blade can be a major problem, especially if the blade is left unused for a while. Rust can damage the blade’s performance, making cutting less efficient and more difficult.

To avoid rust, it’s important to store and maintain your circular saw blades properly. Regular cleaning and proper storage are the keys to preventing rust buildup and prolonging the life of your tools.

Tips for Preventing Rust on Your Circular Saw Blade

- Store the Blade Properly: Always store the saw blade in a dry, cool environment. Avoid leaving it in a damp shed or garage.

- Clean After Every Use: After every use, clean the blade with a damp cloth to remove any dust, sap, or other residue that could contribute to rust formation. Dry it thoroughly before storing.

- Use Blade Oil4: After cleaning, apply a thin coat of blade oil or motor oil to the blade. This helps to create a protective barrier that prevents rust.

- Avoid Contact with Water: Never allow the blade to come into contact with water. If it does, dry it immediately to prevent rust from forming.

- Inspect Regularly: Check the blade for any signs of rust or corrosion and clean it immediately if you see any. Regular maintenance can prevent minor rust spots from becoming bigger issues.

Conclusion

Using a circular saw blade on a miter saw is possible, but it requires careful consideration of the blade’s teeth, material, and application. Always ensure you choose the right blade for the task, especially when working with tricky materials like melamine. With the proper maintenance and handling, you can extend the life of your saw blade and achieve precise, clean cuts.

-

"Triple Chip Grind (TCG)" design is ideal for cutting harder materials like plastic and metal. ↩

-

Laminate cutting is a common topic that often requires specialized techniques or tools. ↩

-

Painter’s tape prevents chipping along the cut line, a common issue when working with melamine. ↩

-

Applying oil to the blade is a proven way to prevent rust. ↩