Can you Use a Diamond Blade to Cut Metal?

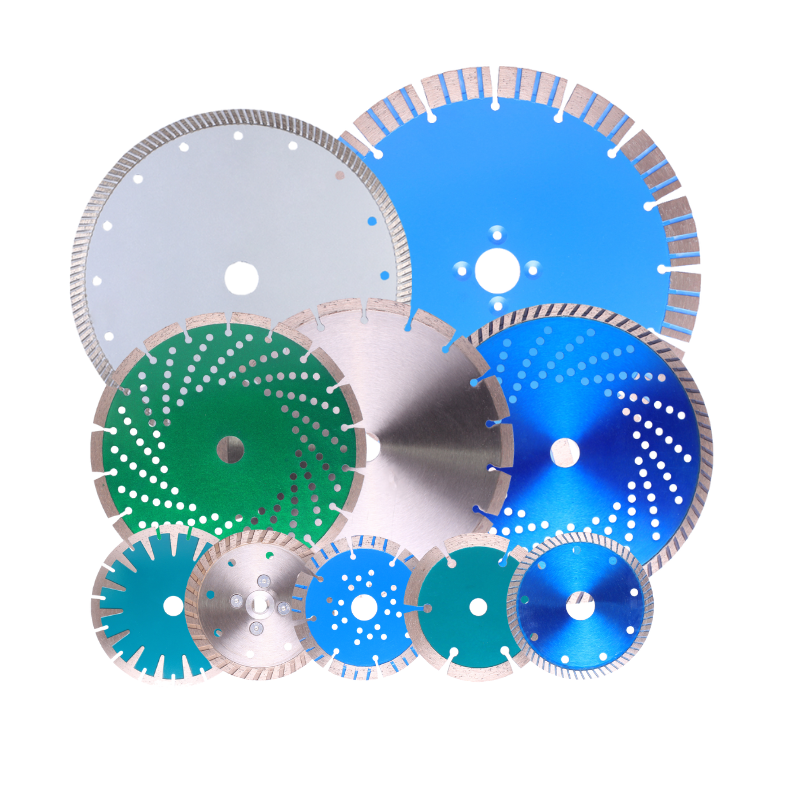

Diamond blades are known for their incredible cutting power, but can they be used for cutting metal? In this article, we will explore whether a diamond blade can handle the challenge of cutting through metal and what makes these blades so effective for different materials.

No, diamond blades cannot cut metal directly. Diamond blades are primarily designed for cutting hard materials like concrete, stone, and ceramics. While they can sometimes handle specific metals, they are not the ideal tool for cutting metal efficiently or effectively. The material of the metal and the blade design play key roles in determining the blade’s performance.

Transitioning to the next part of this article, let’s dive into the specific materials used in concrete saw blades and whether diamond blades are suitable for all types of metal.

What are Concrete Saw Blades Made of?

Materials Used in Concrete Saw Blades

Concrete saw blades are essential tools for cutting through tough materials like concrete, stone, and masonry. But what exactly are these blades made of? The answer lies in the construction of the blade itself.

Concrete saw blades are typically made of high-strength steel, with a diamond edge for cutting through hard materials. The body of the blade is often constructed from high-carbon steel or stainless steel, while the cutting edge is embedded with diamond particles, which are known for their hardness and cutting efficiency.

Alternative Expression for Dive deeper paragraph:

The design of a concrete saw blade is focused on durability and cutting precision. The core of the blade is usually made from robust steel, and it is coated with industrial diamonds to create a sharp, resilient cutting edge. These diamonds allow the blade to easily slice through extremely tough materials such as concrete and stone, where regular saw blades would struggle to perform.

Additionally, concrete blades are often segmented to reduce friction and keep the blade cool during use. The segments1 are the notched parts of the blade that allow for better debris removal and a smoother cutting process. If you are dealing with hard materials like concrete, the diamond segments ensure that the blade remains effective for long periods, even when subjected to harsh working conditions.

When it comes to cutting metal, the choice of the diamond blade’s bond is crucial. A blade with a bond that’s too soft might wear out quickly, especially when cutting tougher metals, while a harder bond is better for longer-lasting performance. This is why there are specialized diamond blades designed specifically for metal cutting.

Can a Diamond Blade Cut through Strong and Thick Steel?

Steel Cutting with Diamond Blades

Diamond blades are extremely powerful and capable of cutting through a wide variety of materials. But when it comes to cutting strong and thick steel, can they still deliver the same results?

No, diamond blades are not ideal for cutting strong and thick steel. While diamond blades can handle some softer metals, they are generally not designed for tougher, thicker metals such as steel. Steel requires a blade designed specifically for metal cutting, as diamond blades may wear down quickly or fail to deliver clean cuts.

Alternative Expression for Dive deeper paragraph:

Cutting strong and thick steel requires more than just a regular diamond blade. Steel’s hardness and density can cause even high-quality diamond blades to wear down quickly if not used correctly. The material’s thickness and composition also play a key role in the blade’s performance. For example, cutting through high-carbon steel2 or hardened steel can be particularly challenging for standard blades.

To address these challenges, manufacturers have designed metal-cutting diamond blades with specialized bonds that are better suited for tougher materials. These blades feature diamonds that are arranged in a way that helps to maintain their sharpness and prevent them from dulling too soon. The cutting process is further enhanced by the blade’s ability to dissipate heat more effectively, ensuring that the blade doesn’t overheat and lose its cutting ability.

Therefore, while diamond blades can handle strong and thick steel, it is crucial to choose a blade that is specifically made for the type of metal you are cutting. Using a blade with the right bond and segment configuration will result in cleaner cuts and longer blade life.

Can a Diamond Saw Blade be Used for Cutting Wood?

Wood Cutting and Diamond Blades

A common misconception is that diamond blades are only for cutting hard materials like stone and concrete. But what about softer materials like wood? Can a diamond saw blade be used for cutting wood effectively?

While diamond blades can technically cut through wood, they are not the ideal choice. Traditional wood-cutting saw blades are specifically designed with teeth that allow them to easily slice through wood fibers. Diamond blades, on the other hand, are optimized for cutting much harder materials.

Alternative Expression for Dive deeper paragraph:

Although diamond blades are incredibly durable, they are generally not designed to cut through wood effectively. Wood-cutting blades typically have teeth that are sharp and designed to slice through the grain of the wood, making them more suited to the task. In contrast, diamond blades use abrasive particles that may create rough, uneven cuts in wood. This can lead to splintering and other issues that are undesirable in woodworking.

Moreover, using a diamond blade3 for wood can result in unnecessary wear and tear on the blade itself. Since the blade is built for cutting harder materials, it might degrade more quickly when used on wood. On top of this, diamond blades can be much more expensive than traditional wood-cutting blades, making them an impractical choice for most wood-related projects.

While there are certain situations where a diamond blade might be useful, such as cutting wood that is mixed with other materials like concrete or metal, it is usually better to stick to a blade that’s specifically designed for wood cutting. This will ensure smoother cuts and save you money in the long run.

What Saw Blade Cuts Concrete?

Diamond Blades for Concrete Cutting

Concrete is one of the toughest materials to cut through, requiring specialized tools. But what kind of saw blade is best suited for cutting concrete?

A diamond saw blade is the best choice for cutting concrete. Diamond blades are designed to handle tough materials like concrete, and their ability to resist wear and tear makes them the go-to option for this type of cutting task.

Alternative Expression for Dive deeper paragraph:

When it comes to cutting through concrete, a diamond blade is unbeatable. These blades are specially designed with diamond segments that are bonded to the edge of the steel core. The diamonds’ hardness allows the blade to cut through even the most difficult materials without losing sharpness too quickly.

Concrete saw blades come in different designs, such as continuous rim and segmented types. The continuous rim blade provides a smooth cutting edge for finer cuts, while the segmented blade offers more aggressive cuts and a longer lifespan, making it ideal for tougher concrete.

Another crucial factor in concrete cutting is cooling4. Diamond blades can generate a lot of heat, so using a wet-cutting blade is often recommended for large jobs. Water cools the blade and helps reduce dust, keeping both the blade and the surrounding environment safer and more efficient.

For smaller jobs or locations where water is not feasible, dry-cutting diamond blades are also available. While they are not as effective in controlling heat and dust, they still provide reliable results, especially for smaller, less intensive tasks.

In conclusion, diamond blades are the best tool for cutting concrete, providing efficiency, precision, and longevity.

Conclusion

In summary, diamond blades cannot cut metal effectively. They are better suited for materials like concrete and stone, and metal cutting requires a blade specifically designed for that purpose.

-

Adding this link helps explain the technical benefits of blade segmentation, particularly in terms of heat reduction, debris removal, and smoother cutting. ↩

-

"High-carbon steel" is a tough material and cutting it requires specific techniques or tools. ↩

-

This is important for users who may be wondering about specific use cases for diamond blades. ↩

-

Cooling is an important factor in concrete cutting. ↩