How to Choose the Right Saw Blade for Your Business Needs

When choosing a saw blade, it’s important to think about the material you’re cutting, the quality you need, and the cost. In this article, I’ll guide you through the key factors to help you pick the best saw blade for your business.

What Should You Consider When Choosing a Saw Blade?

When selecting a saw blade, focus on the material, precision, cost, and whether you need customization. The blade should match your project’s needs, offering the best balance of performance, durability, and price. Look for certified, high-quality blades that fit your budget.

What Are the Key Factors to Evaluate When Choosing a Saw Blade?

How Do You Choose the Right Material for a Saw Blade?

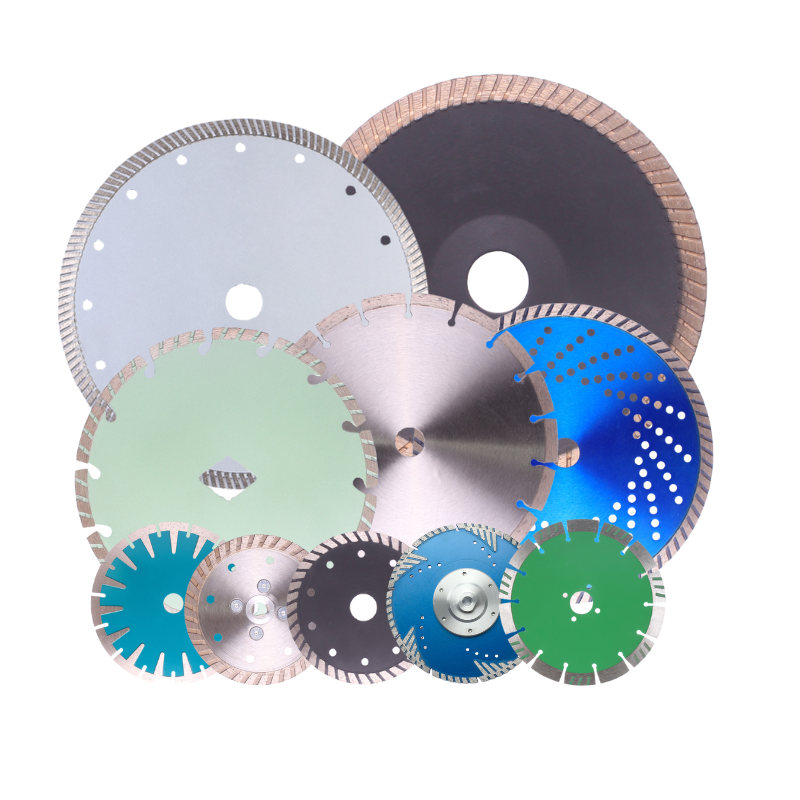

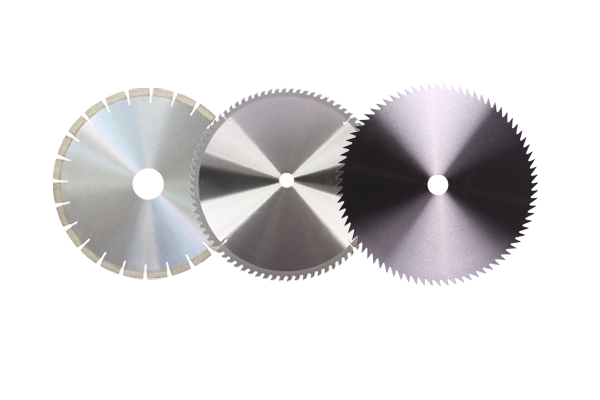

The material of the saw blade will affect its cutting ability. Some materials are better for cutting hard substances, while others are designed for softer materials1. Knowing which one works best for your needs will help you make a better choice.

Material Selection Snippet:

The material of the blade is important for durability and cutting power. For example, carbide-tipped blades are perfect for cutting metal, while high-speed steel blades work well for cutting wood. Always choose the right material based on your specific needs.

Dive Deeper: Choosing the Right Material

Choosing the right material for your saw blade depends on what you’re cutting. Carbide-tipped blades are great for cutting harder materials like metal, aluminum, and steel. These blades last longer and stay sharp, so they’re a good investment for tough jobs.

High-speed steel (HSS) blades are more affordable and work well for softer materials like wood or plastic. They can’t cut as fast or last as long as carbide-tipped blades, but they are perfect for general-use applications.

Diamond blades are ideal for cutting very hard materials like concrete or stone. They are expensive but offer great performance in demanding tasks, providing fast cuts with little wear and tear.

The key is to match the blade material with your needs. For tougher materials, spend a bit more on carbide-tipped or diamond blades. For basic tasks, HSS blades will do the job without the extra cost.

Why Is Precision and Stability Important?

Precision and stability are important for getting clean and accurate cuts. A blade that wobbles or vibrates can cause rough cuts, which might affect the quality of your work. High-precision blades are designed to stay steady during use.

Precision and Stability Snippet:

Precision blades offer stable cuts without wobbling, ensuring smooth finishes. If your project requires accurate cuts, high-precision saw blades are a must.

Dive Deeper: Precision and Stability

Precision and stability are especially important when you need clean cuts. Laser-cut blades are one of the best options for high-precision work. These blades are cut with a laser, which ensures uniform thickness and reduces the chance of blade deformation during use. The result is a smoother, cleaner cut.

Stabilized blades are designed to reduce vibrations, making them more reliable for delicate cutting jobs. These are often used in high-speed or automated cutting systems.

Blade thickness also impacts precision. Thicker blades tend to be more stable, but they may take longer to cut. Thinner blades, while faster, can be less stable and produce rougher cuts. It’s all about balancing the right thickness for your cutting needs.

How Can Customization Improve Your Business?

Customization can help you stand out in a crowded market. Offering personalized blades with logos, custom packaging, or special coatings can add value for your customers. Customization makes your products unique and can help build a strong brand.

Customization Snippet:

Customizing your saw blades—whether it’s branding, packaging, or coatings—can boost your business. Customization allows you to meet client needs while building brand identity.

Dive Deeper: Customization Options

Customization is a great way to enhance your brand and meet specific customer needs. Many manufacturers, including TENYU TOOL, offer custom branding, such as logo engraving on blades or personalized packaging. This adds a unique touch and helps your products stand out in the market.

Coatings like Teflon or chrome can protect blades from rust and wear, while also improving cutting performance. These coatings can also reduce friction, which extends the life of the blade.

When considering customization, think about how it fits your business strategy. If you’re targeting high-end customers, consider offering high-quality packaging and special coatings. If your focus is cost efficiency, stick to affordable options but still ensure high-quality performance.

Conclusion

Choosing the right saw blade is all about understanding your material, precision needs, and customization options. By considering these factors, you can find the blade that best fits your business, ensuring quality and efficiency.

-

Refers to the different types of substances used to manufacture saw blades, and it’s important to know which type of material suits your specific cutting needs. ↩