Cutting the bottom off a glass bottle can transform it into a beautiful vase or a unique drinking glass. But it’s not as simple as it seems.

To cut the bottom off a glass bottle, you need the right tools and techniques to ensure a clean and safe result.

Keep reading to discover the best methods and tips for successfully cutting glass bottles.

How to Cut the Bottom Off a Glass Bottle?

Have you ever tried cutting a glass bottle and ended up frustrated? It’s a common struggle.

Cutting the bottom off a glass bottle requires careful planning and the proper tools to achieve a smooth finish.

Let’s explore the step-by-step process to make this task easier and more efficient.

Tools You’ll Need

To cut the bottom off a glass bottle, gather the following tools:

- Glass bottle

- Diamond-tipped glass cutter

- Rubbing alcohol

- Vegetable oil

- Candle or small lamp

- Protective gloves

- Safety goggles

Step-by-Step Guide

- Mark the Bottle: Use a marker to indicate where you want to cut.

- Heat the Marked Area: Apply rubbing alcohol1 with a cotton ball around the mark.

- Apply Oil: Spread vegetable oil over the alcohol-soaked area.

- Heat the Bottle: Light a candle or lamp and move it around the marked area to create heat.

- Score the Bottle: Use the glass cutter to score along the heated line.

- Cool the Bottle: Immerse the bottle in cold water to help it break cleanly.

- Remove the Bottom: Gently twist and pull the bottom off along the scored line.

- Smooth the Edges: Use sandpaper or a sanding stone to smooth any rough edges.

Tips for a Successful Cut

- Consistency is Key: Ensure even heating around the marked line for a clean break.

- Safety First: Always wear protective gloves and goggles to prevent injuries.

- Practice Makes Perfect: If you’re new to glass cutting, practice on a spare bottle first.

Common Mistakes to Avoid

- Uneven Heating: Inconsistent heating can lead to uneven breaks.

- Skipping Safety Gear: Not wearing gloves and goggles increases the risk of injury.

- Rushing the Process: Taking your time ensures a cleaner and safer cut.

Enhancing Your Technique

Practicing on different types of glass bottles can help improve your cutting technique. Experiment with various heating sources and scoring tools to find what works best for you.

How to Drill Holes in Glass: Tips and Techniques

Drilling holes in glass can be tricky and intimidating. Many worry about cracking or shattering the glass.

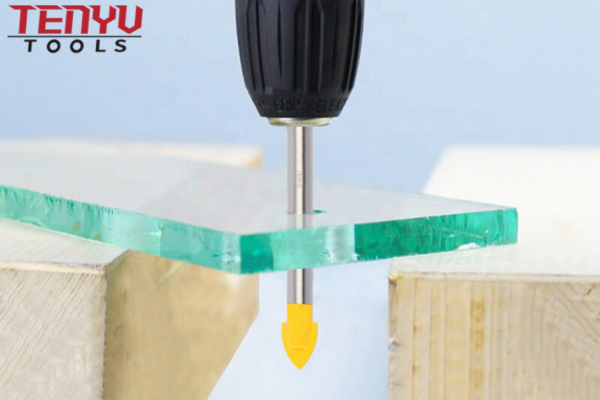

Drilling holes in glass requires precision and the right drill bits to prevent damage and achieve clean results.

Let’s dive into the best practices for drilling glass without causing harm.

Choosing the Right Drill Bit

For drilling holes in glass, Carbide Tip Drill Bits are highly recommended. These bits are durable and designed to handle the hardness of glass.

Why Carbide Tip Drill Bits?

- Durability: They last longer than standard bits.

- Precision2: Provide cleaner and more accurate holes.

- Heat Resistance: Can withstand the heat generated during drilling.

Preparing to Drill

- Mark the Spot: Clearly mark where you want to drill the hole.

- Secure the Glass: Use clamps to hold the glass steady on a soft surface.

- Use Water: Keep the drilling area wet to reduce heat and prevent cracking.

Drilling Technique

- Start Slow: Begin drilling at a low speed to create a small indentation.

- Increase Speed Gradually: Once the bit grips, slowly increase the drill speed.

- Apply Gentle Pressure: Let the drill bit do the work without forcing it.

- Keep it Wet: Continuously apply water to the drilling area to cool the bit and glass.

Common Mistakes to Avoid

- Too Much Pressure: Pressing too hard can crack the glass.

- High Speed: Drilling too fast generates heat, increasing the risk of breaking.

- Skipping Lubrication: Not using water can cause overheating and damage.

After Drilling

Once the hole is drilled, carefully remove any rough edges with sandpaper or a sanding stone to ensure a smooth finish.

Enhancing Precision with Carbide Tip Drill Bits

Using Carbide Tip Drill Bits significantly improves the drilling process. Their superior design allows for better control and reduces the risk of damaging the glass. Investing in high-quality drill bits ensures that each hole you drill is clean and precise, saving you time and effort in the long run.

Table: Comparison of Drill Bits for Glass

| Drill Bit Type | Durability | Precision | Heat Resistance | Recommended Use |

|---|---|---|---|---|

| Carbide Tip Drill Bits | High | High | High | General glass drilling |

| Diamond-Tipped Drill Bits | Medium | Medium | Medium | Specialized applications |

| Standard Metal Drill Bits | Low | Low | Low | Not recommended for glass |

Safety Tips

- Wear Protective Gear: Always use gloves and goggles to protect yourself from glass shards.

- Work in a Well-Ventilated Area: Drilling glass can produce fine particles that are best handled in a ventilated space.

- Use a Stable Surface: Ensure your glass is securely clamped to prevent movement during drilling.

How to Cut a Square Hole in Glass?

Cutting a square hole in glass adds a unique touch to your projects, but it can be challenging.

Creating a square hole in glass involves precision and specialized tools to maintain the integrity of the glass.

Here’s how to achieve a perfect square hole in your glass projects.

Tools Needed

- Glass cutter

- Diamond-tipped drill bits

- Carbide Tip Drill Bits

- Sandpaper

- Safety equipment

Step-by-Step Process

- Mark the Square: Use a marker to outline the square shape on the glass.

- Score the Glass: Carefully score along the marked lines using a glass cutter.

- Drill the Corners: Use Carbide Tip Drill Bits3 to drill small holes at each corner of the square.

- Apply Heat and Cold: Heat the scored lines with a candle and then quickly cool them with cold water.

- Snap the Glass: Gently press along the scored lines to break the glass into a square shape.

- Smooth the Edges: Sand the edges to remove any sharpness and ensure a clean finish.

Tips for Success

- Precision Marking: Accurate marking ensures the square is even and symmetrical.

- Controlled Pressure: Apply even pressure when scoring and snapping the glass to prevent cracks.

- Cooling and Heating: Properly alternating heat and cold helps in achieving a clean break.

Common Challenges

- Uneven Breaks: Inconsistent pressure can lead to uneven or jagged edges.

- Cracks: Excessive force or improper technique can cause the glass to crack.

- Edge Smoothness: Failing to smooth the edges can result in rough and unsafe surfaces.

Enhancing Your Technique

Practicing on scrap glass pieces can help improve your technique and confidence. Experiment with different drilling speeds and pressure levels to find what works best for you.

H3: Advanced Techniques for Square Holes

For more precise square holes, consider using templates and guides. A template ensures that your markings are accurate, and a guide helps maintain a steady hand while scoring the glass. Additionally, using a glass cutting jig can provide the necessary support to achieve straight and clean lines.

Table: Tools for Cutting Square Holes

| Tool | Purpose | Recommended Brand |

|---|---|---|

| Glass Cutter | Scoring the glass | Newell & Goodrich |

| Carbide Tip Drill Bits | Drilling precise holes without cracking | Tenyu |

| Sandpaper | Smoothing rough edges | 400-600 grit |

| Glass Cutting Jig | Supporting the glass during cutting | Custom-made |

| Template and Guide | Ensuring accurate markings and straight lines | DIY or purchased |

Safety Precautions

- Protect Your Eyes: Always wear safety goggles to shield your eyes from glass shards.

- Handle Glass Carefully: After cutting, handle the glass with care to avoid injury from sharp edges.

- Work Slowly: Take your time with each step to ensure precision and safety.

How to Cool Down a Drill Bit?

Keeping your drill bit cool is essential to prevent damage and ensure efficient drilling, especially with glass.

Cooling down a drill bit during use extends its lifespan and maintains its cutting efficiency.

Here’s how to effectively cool your drill bit while working on glass projects.

Importance of Cooling

- Prevents Overheating4: Reduces the risk of melting or damaging the glass.

- Extends Bit Life: Keeps the drill bit sharp and functional longer.

- Enhances Precision: Maintains consistent cutting performance.

Methods to Cool Your Drill Bit

- Water Lubrication: Continuously apply water to the drilling area to keep the bit cool.

- Cooling Fluids: Use specialized cooling fluids designed for glass drilling.

- Frequent Pauses: Take breaks during drilling to allow the bit to cool naturally.

- Air Cooling: Use compressed air to blow away heat from the drill bit.

Best Practices

- Steady Application: Ensure a constant flow of water or cooling fluid while drilling.

- Avoid Dry Drilling: Never drill glass without some form of cooling to prevent damage.

- Monitor Temperature: Feel the drill bit periodically to ensure it’s not getting too hot.

Using Carbide Tip Drill Bits for Better Cooling

Carbide Tip Drill Bits are excellent for glass drilling because they handle heat better and maintain their sharpness longer. This reduces the need for excessive cooling and makes the drilling process smoother.

Troubleshooting Overheating

- Bit Glazing: If the bit becomes glazed, stop drilling and clean it before continuing.

- Glass Cracking: If the glass starts to crack, immediately stop and reassess your technique.

- Reduced Efficiency: If drilling becomes slower, check if the bit needs cooling or sharpening.

Maintenance Tips

Regularly clean your drill bits to remove glass residue and prevent buildup. Store them in a dry place to avoid rust and corrosion, ensuring they’re ready for your next project.

H3: Advanced Cooling Techniques

For larger projects or multiple holes, consider investing in a drill press with built-in cooling systems. These systems provide consistent cooling, allowing for longer drilling sessions without overheating the bits. Additionally, using a dedicated cooling station where you can quickly dip and cool your drill bits can save time and improve efficiency.

Table: Cooling Methods Comparison

| Cooling Method | Pros | Cons |

|---|---|---|

| Water Lubrication | Easy to apply, inexpensive | May require frequent refilling |

| Cooling Fluids | More effective for high-precision work | Can be more expensive |

| Frequent Pauses | Simple to implement | Slows down the drilling process |

| Air Cooling | No mess, quick cooling | Less effective for prolonged use |

| Drill Press Cooling | Consistent and efficient cooling | Higher initial investment |

Safety Tips

- Handle Cooling Fluids Safely: Use gloves and work in a ventilated area when handling specialized cooling fluids.

- Prevent Slips: Ensure the drilling area is dry except for the cooling application to prevent slipping.

- Regular Inspection: Frequently check your drill bits and cooling systems for any signs of wear or malfunction.

Conclusion

Cutting and drilling glass requires the right tools and techniques. Using Carbide Tip Drill Bits ensures precision and durability for your projects.

-

Rubbing alcohol is a common substance used to clean glass surfaces before scoring or cutting. ↩

-

Precision is important in various drilling applications. ↩

-

Carbide Tip Drill Bits are a specialized tool used for precise drilling in materials like glass. ↩

-

Overheating can compromise the integrity of cutting tools and damage glass. ↩