Drilling glass can seem challenging, but with the right approach, it’s achievable.

Drilling a hole in glass requires the proper tools and techniques to ensure precision and safety.

Let’s explore how you can achieve clean and accurate holes in glass without the stress.

How To Drill Holes Through Glass?

Struggling with glass breaking during drilling?

To drill holes through glass, use a carbide-tipped drill bit and go slowly with steady pressure.

Understanding the correct method is key to preventing glass breakage and achieving a smooth finish.

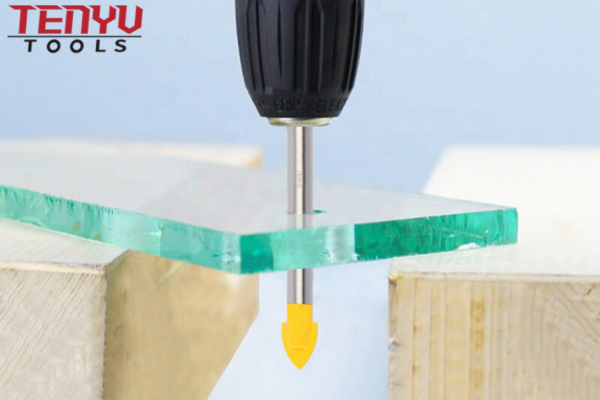

Choosing the Right Drill Bit

Selecting the appropriate drill bit is crucial. Carbide-tipped bits1 are excellent for glass as they provide the necessary precision without causing cracks. Regular bits can easily slip or break the glass due to their hardness.

Preparing the Glass

Before drilling, mark the spot accurately. Secure the glass on a stable surface to prevent movement. Applying a small amount of masking tape on the drilling spot can help keep the drill bit from slipping.

Drilling Technique

Start drilling at a low speed to create a small groove. Gradually increase the speed while maintaining steady pressure. Keep the glass and drill bit cool by using water to reduce friction and prevent overheating.

Safety Precautions

Always wear protective eyewear and gloves. Drilling glass generates sharp edges and small glass particles, so safety is paramount to avoid injuries.

Table: Drill Bit Types for Glass

| Drill Bit Type | Suitable For | Advantages |

|---|---|---|

| Carbide-tipped | All glass types | Precision, durability |

| Diamond-tipped | Tempered glass | High precision, long-lasting |

| Specialty Bits | Stained glass | Customized shapes and sizes |

How To Drill Through Glass Safely and Effectively?

Worried about shattering your glass project?

Drilling through glass safely involves using carbide-tipped bits, proper techniques, and protective measures.

Ensuring safety and effectiveness requires careful planning and execution.

Essential Tools for Safe Drilling

Using a quality drill2 with variable speed control is essential. A drill press can offer more stability compared to a handheld drill. Additionally, using a center punch can help guide the carbide-tipped drill bit accurately.

Securing the Glass

Clamping the glass securely on a padded surface prevents movement. This stability reduces the risk of slipping and breaking the glass during drilling.

Cooling the Drill Bit

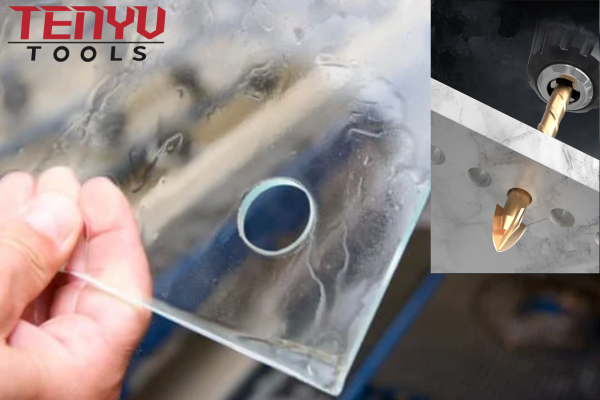

Keeping the drill bit cool is vital. Use a constant stream of water or a specialized cooling system to minimize heat buildup, which can cause cracks or breaks.

Drilling in Stages

Start with a small pilot hole and gradually increase the size. This staged approach reduces stress on the glass and ensures a cleaner hole.

Personal Safety Gear

Wearing safety goggles, gloves, and protective clothing shields you from accidental glass shards and debris during the drilling process.

Table: Benefits of Carbide-Tipped Bits

| Feature | Description |

|---|---|

| Durability | High resistance to wear and tear |

| Precision | Allows for accurate and clean holes |

| Versatility | Suitable for various glass types |

| Cost-Effectiveness | Offers a balance between quality and price |

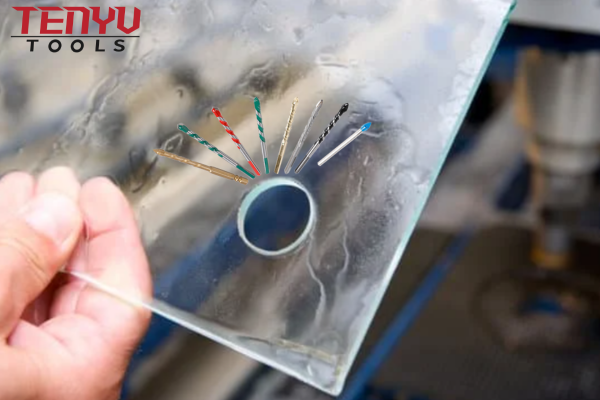

What Bit Should I Use to Drill a Hole In the Glass?

Confused about which drill bit to choose for glass?

A carbide-tipped drill bit is the best choice for drilling holes in glass due to its hardness and precision.

Selecting the right bit ensures smooth drilling and minimizes the risk of damage.

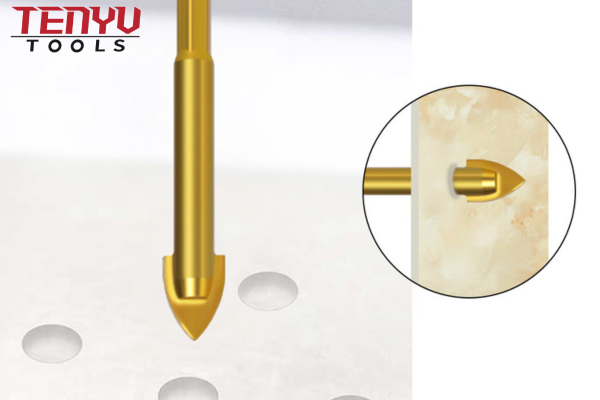

Carbide-Tipped Drill Bits

Carbide-tipped bits are designed specifically for tough materials like glass3. They provide a clean and precise hole with minimal effort, making them ideal for both DIY projects and professional use.

Diamond-Tipped Drill Bits

While diamond-tipped bits are also effective, carbide-tipped bits offer a more cost-effective solution without compromising on quality. They are especially suitable for thicker glass where durability is essential.

Specialty Glass Drill Bits

Some drill bits are specifically designed for glass, featuring unique shapes and coatings to reduce friction and enhance performance. These can be a good investment for frequent glass drilling tasks.

Comparing Drill Bits

| Drill Bit Type | Durability | Precision | Cost |

|---|---|---|---|

| Carbide-Tipped | High | Excellent | Moderate |

| Diamond-Tipped | High | Excellent | Higher |

| Specialty Glass Bits | Variable | High | Variable |

Maintenance of Drill Bits

Proper maintenance extends the life of your drill bits. Clean them after each use and store them in a dry place to prevent rust and wear. Regularly inspect carbide-tipped bits for any signs of damage or dullness to ensure optimal performance.

How Do You Bore a Hole into a Glass Without Breaking It?

Fear breaking the glass while boring a hole?

Boring a hole into glass without breaking it requires patience, a carbide-tipped bit, and careful technique.

By following the correct steps, you can achieve a clean hole without compromising the glass integrity.

Marking the Drilling Point

Accurately mark where you want to drill. Using a marker4 or tape helps guide the carbide-tipped drill bit and prevents slipping.

Starting the Drill

Begin drilling at a low speed to create a small indentation. This initial groove helps stabilize the bit and prevent skidding.

Applying Gentle Pressure

Apply steady, gentle pressure throughout the drilling process. Excessive force can cause the glass to crack or shatter.

Using Lubrication

Lubricate the drilling area with water or a specialized lubricant to reduce heat and friction, ensuring a smoother drilling experience.

Gradual Drilling Process

Drill slowly and incrementally, allowing the bit to gradually penetrate the glass. Rushing the process increases the risk of breakage.

Inspecting the Hole

Periodically inspect the hole to ensure it is progressing correctly. Adjust your technique as needed to maintain control and precision.

Table: Step-by-Step Boring Process

| Step | Action |

|---|---|

| 1. Marking | Use a marker or tape to mark the spot |

| 2. Securing | Clamp the glass securely |

| 3. Starting Drill | Drill at low speed to create an indent |

| 4. Applying Pressure | Use steady, gentle pressure |

| 5. Lubricating | Apply water or lubricant continuously |

| 6. Gradual Drilling | Increase speed gradually |

| 7. Inspecting | Check the hole periodically |

What Bit Can be Used for Drilling a Hole In a Glass Bottle?

Struggling to find the right bit for glass bottles?

A carbide-tipped drill bit is ideal for drilling holes in glass bottles, providing precision and durability.

Using the correct bit ensures a smooth drilling process and prevents damage to the bottle.

Selecting the Right Size Bit

Choose a bit size that matches the desired hole diameter. Smaller carbide-tipped bits5 are easier to control and reduce the risk of cracking the glass.

Preparing the Bottle

Clean the bottle thoroughly and mark the drilling spot. Securing the bottle with clamps or a stable holder prevents movement during drilling.

Drilling Technique for Bottles

Drill at a low speed, applying even pressure. Use water to keep the bit cool and minimize heat buildup, which can weaken the glass.

Preventing Bottle Breakage

Avoid drilling too close to the edges or seams of the bottle, as these areas are more prone to cracking. Maintain a steady hand to ensure a clean, even hole.

Finishing the Hole

After drilling, smooth the edges with fine-grit sandpaper or a glass file to remove any sharp edges and ensure a safe finish.

Table: Best Practices for Drilling Glass Bottles

| Practice | Description |

|---|---|

| Bit Selection | Use carbide-tipped bits for precision |

| Bottle Preparation | Clean and mark accurately |

| Securing the Bottle | Clamp securely to prevent movement |

| Drilling Speed | Keep speed low to maintain control |

| Cooling Method | Continuously apply water to cool the bit |

| Edge Finishing | Smooth edges with sandpaper after drilling |

Can You Drill Glass Without Water?

Thinking of drilling glass without using water?

While it is possible to drill glass without water, using water is highly recommended to prevent overheating and cracking.

However, if water is unavailable, certain precautions can help mitigate risks.

Risks of Drilling Without Water

Without water, heat buildup can cause the glass6 to crack or shatter. The drill bit can also wear out faster due to increased friction.

Alternative Cooling Methods

If water isn’t an option, use a cooling lubricant or take frequent breaks to allow the drill bit and glass to cool down. This reduces the risk of heat-related damage.

Drilling Technique Adjustments

Drill at an even slower speed and apply minimal pressure. This helps control the heat generation and maintain stability during drilling.

Protective Measures

Wear safety gear, including goggles and gloves, to protect against potential glass shards and overheating. Ensure the drilling area is well-ventilated to disperse heat.

Post-Drilling Care

After drilling, inspect the glass for any signs of stress or cracks. Allow the glass to cool naturally before handling to prevent further damage.

Table: Comparison of Cooling Methods

| Cooling Method | Advantages | Disadvantages |

|---|---|---|

| Water Cooling | Effective heat reduction | Requires access to water |

| Cooling Lubricants | Reduces friction and heat | May leave residue on glass |

| Frequent Breaks | Prevents continuous heat buildup | Slows down the drilling process |

| Air Cooling | No additional materials needed | Less effective in high-friction areas |

How to Make a Small Hole in Thin Glass?

Need a precise small hole in thin glass?

Making a small hole in thin glass requires a carbide-tipped bit and careful handling to achieve a clean result without breaking the glass.

With the right approach, even thin glass can be drilled accurately and safely.

Choosing the Right Drill Bit

A fine carbide-tipped drill7 bit is perfect for small holes in thin glass. Its precision allows for accurate drilling without excessive pressure.

Marking and Securing

Carefully mark the exact spot for the hole. Secure the glass on a soft, stable surface to prevent slipping and ensure steady drilling.

Drilling Process

Start drilling at a very low speed to create a small indent. Gradually increase the speed while maintaining steady, light pressure to avoid cracking the glass.

Cooling the Drill Bit

Use a gentle stream of water to keep the drill bit cool. This prevents overheating and reduces the risk of damaging the thin glass.

Finishing Touches

Once the hole is drilled, smooth the edges with fine sandpaper or a glass file. This ensures a clean, safe finish without sharp edges.

Troubleshooting Common Issues

- Bit Slipping: Ensure the mark is clear and start drilling with a pilot hole.

- Overheating: Maintain a consistent cooling method and avoid prolonged drilling in one spot.

- Cracking: Apply even pressure and avoid sudden movements to keep the glass intact.

Table: Steps to Drill Small Holes in Thin Glass

| Step | Action |

|---|---|

| 1. Bit Selection | Choose a fine carbide-tipped bit |

| 2. Marking | Accurately mark the drilling spot |

| 3. Securing | Clamp the glass securely |

| 4. Starting Drill | Drill at low speed to create an indent |

| 5. Gradual Speed Up | Slowly increase the drilling speed |

| 6. Cooling | Continuously apply a gentle water stream |

| 7. Finishing | Smooth edges with sandpaper or a file |

| 8. Inspection | Check for any cracks or imperfections |

Conclusion

Drilling glass is achievable with carbide-tipped bits and the right techniques. Follow these steps for successful results.

-

"Carbide-tipped bits" refers to a specific type of drill bit with unique properties. ↩

-

Drills are an essential tool in various DIY and professional tasks. ↩

-

Adding a link to this keyword will help provide further information about glass as a material that carbide-tipped bits are particularly suited for. ↩

-

Markers are a common tool used to ensure precise drilling locations. ↩

-

"carbide-tipped bits" will provide users with detailed information about their properties, usage, and advantages, particularly in tasks. ↩

-

Glass is a brittle material, and heat buildup can cause it to expand and contract rapidly, leading to cracking or shattering. ↩

-

Carbide-tipped drill bits are often recommended for specific materials, including glass, due to their durability and precision. ↩