Have you ever needed to make a hole in a glass bottle but didn’t have a drill?

You can make a hole in a glass bottle without a drill using simple tools and careful techniques.

Don’t worry if you lack specialized tools. Keep reading to discover effective methods.

How to Make a Hole In a Glass Bottle Without a Drill?

Have you found yourself needing to make a hole in a glass bottle but don’t have a drill?

You can successfully create a hole using household items and careful techniques.

Stay with me to learn the step-by-step process.

Dive deeper Paragraph

Making a hole in a glass1 bottle without a drill might seem daunting, but it’s entirely achievable with the right approach. Start by gathering the necessary materials: a glass bottle, a hammer, a nail or a sharp metal object, protective gloves, and safety glasses. Begin by marking the spot where you want the hole. This ensures precision and helps prevent accidental slips. Wearing gloves and safety glasses is crucial to protect yourself from potential glass shards. Using the hammer and nail, gently tap the nail into the glass at the marked spot, creating a small indentation. This indentation serves as a guide and reduces the risk of the glass cracking uncontrollably. Once the initial mark is made, continue to tap gently, gradually widening the hole. It’s essential to work slowly and apply even pressure to maintain control over the process. Additionally, lubricating the area with a bit of oil or soap can help the nail glide more smoothly into the glass, making the process easier and safer. Patience and steady hands are your best allies in this task.

How Are People Able to Cut Glass Without Shattering It?

Ever wondered how glass can be cut cleanly without breaking?

Experts use precise techniques and tools to make smooth cuts without shattering the glass.

Let’s explore the methods that ensure clean glass cuts every time.

Dive deeper Paragraph

Cutting glass without causing it to shatter involves understanding the properties of glass and applying the right techniques. Glass is a brittle material, meaning it can break easily under stress. To cut it cleanly, one must minimize stress concentrations and apply even pressure. One common method is scoring the glass, which involves making a shallow, precise scratch along the desired cut line using a glass cutter or a sharp tool like a diamond-tipped pen. This score line acts as a controlled weak point. After scoring, the glass is carefully bent along the line, allowing the score to guide the break. Another technique involves using a hot wire or a candle flame to heat the glass along the cut line, followed by rapid cooling with cold water. The thermal shock causes the glass to crack along the heated line. Additionally, using lubricants like cutting oil2 can help reduce friction and heat buildup during the cutting process, leading to smoother cuts. Safety is paramount, so always wear protective gloves and eyewear to guard against accidental breaks. Mastering these techniques requires practice and patience, but with the right approach, clean glass cuts are entirely possible without shattering.

How to Cut Glass Without a Glass Cutter and Without a Laser?

Need to cut glass but don’t have a cutter or laser?

You can cut glass using alternative household items with the right techniques.

Discover easy and effective methods to achieve precise glass cuts.

Dive deeper Paragraph

Cutting glass without a traditional glass cutter or laser involves improvising with available tools while maintaining precision and safety. One effective method is using a diamond-tipped marker or even a permanent marker3 as a makeshift scoring tool. Begin by marking the desired cut line clearly on the glass. Next, use a piece of fine-grit sandpaper or a metal file to follow the marked line meticulously, creating a shallow groove. This groove weakens the glass along the intended path. Once the groove is established, place the glass on a flat, stable surface with the cut line aligned over the edge or a straight edge guide. Apply gentle, even pressure to snap the glass along the groove. Alternatively, you can use a piece of string or dental floss soaked in a little rubbing alcohol. Place it along the cut line and carefully burn it with a candle or lighter, allowing the flame to singe the string. As the string burns, it creates a controlled crack in the glass. After creating the initial break, gently tap along the line to separate the glass. It’s crucial to work slowly and steadily to avoid sudden breaks or shattering. Always wear protective gloves and eyewear to ensure safety during the process. These alternative methods require patience and a steady hand but can yield clean and precise cuts without specialized tools.

Tips on Drilling Through Glass!

Looking to drill through glass without causing damage?

Proper techniques and tools can help you drill through glass smoothly and safely.

Learn essential tips to achieve successful glass drilling.

Dive deeper Paragraph

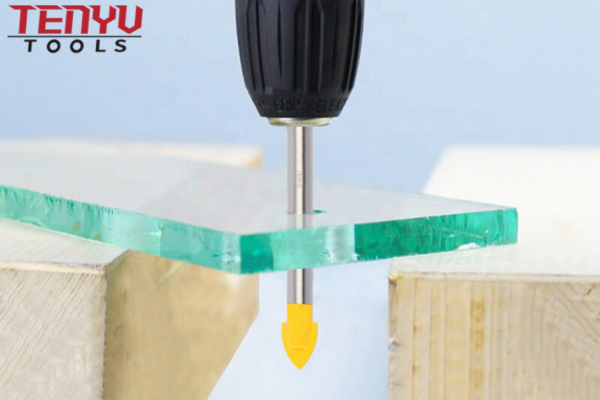

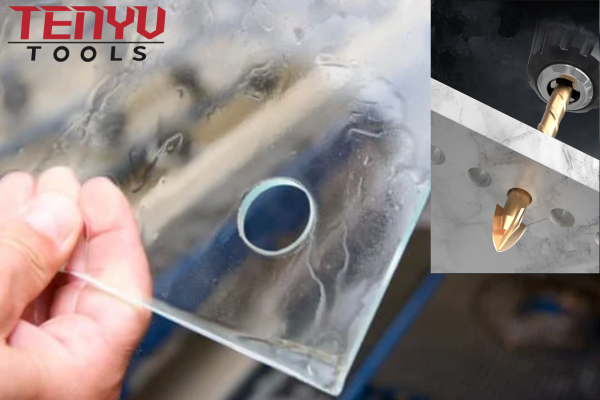

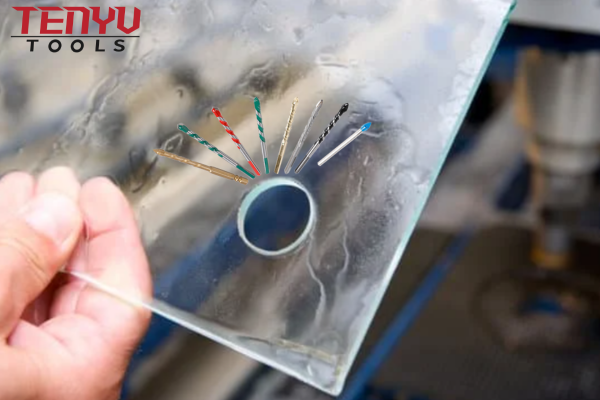

Drilling through glass requires careful preparation and the right techniques to prevent cracking or shattering. Start by selecting the appropriate drill bit; diamond-tipped bits are ideal for glass as they provide the necessary precision and reduce the risk of damage. Before you begin, clean the glass surface to remove any dirt or debris that could interfere with the drilling process. Apply a small amount of water to the drilling area to act as a lubricant and to dissipate heat generated during drilling. Position the glass on a stable, flat surface, preferably using clamps or a vise to secure it firmly. Mark the exact spot where you want to drill to ensure accuracy. When you start drilling, use a low speed setting on your drill to maintain control and reduce heat buildup. Apply gentle, steady pressure, allowing the drill bit to do the work without forcing it. It’s important to keep the drill perpendicular to the glass surface to achieve a straight hole. Take frequent breaks to cool the glass and the drill bit, preventing overheating. After drilling, carefully remove any rough edges around the hole using fine-grit sandpaper or a glass file. Wearing protective gloves and eyewear is essential to safeguard against any accidental glass fragments. With these tips, you can successfully drill through glass, achieving clean and precise holes without causing damage.

Conclusion

Creating holes in glass bottles without specialized tools is achievable with the right techniques and care.