Have you ever struggled with drilling precise holes? Step drill bits might be your solution.

Step drill bits are versatile tools used for creating clean, accurate holes in various materials. They are ideal for tasks requiring multiple hole sizes without changing bits.

Keep reading to discover how step drill bits can enhance your drilling projects.

What Is A Step Drill Bit? Uses & Applications?

Frustrated with switching bits for different hole sizes?

A step drill bit features a conical shape with multiple steps, each representing a different hole size. This design allows for drilling various diameters without changing bits.

Understanding step drill bits can revolutionize your drilling tasks.

Understanding the Design of Step Drill Bits

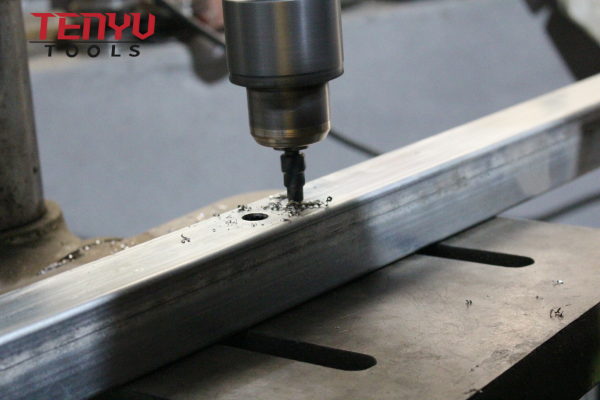

Step drill bits are uniquely designed with a conical1 shape that tapers from a larger diameter at the base to a smaller one at the tip. Each "step" on the bit corresponds to a specific hole size, allowing you to create multiple hole diameters with a single bit. This eliminates the need to switch between different drill bits, saving time and effort.

Common Uses of Step Drill Bits

Step drill bits are commonly used in:

- Sheet Metal Fabrication: Ideal for creating holes in thin metal sheets without deformation.

- Electrical Work: Perfect for drilling precise holes for wiring and conduits.

- Plumbing: Useful for creating holes for pipes and fittings.

- DIY Projects: Great for hobbyists needing various hole sizes without a full set of bits.

Advantages in Different Applications

In sheet metal work, step drill bits provide clean edges and prevent tearing, which is essential for maintaining the integrity of the metal. In electrical and plumbing applications, the ability to drill multiple hole sizes with one bit ensures consistency and efficiency. For DIY enthusiasts, step drill bits offer versatility and convenience, making them a valuable addition to any toolkit.

Table: Step Drill Bit Applications

| Application | Benefits |

|---|---|

| Sheet Metal Fabrication | Clean, precise holes without deformation |

| Electrical Work | Consistent hole sizes for wiring and conduits |

| Plumbing | Accurate holes for pipes and fittings |

| DIY Projects | Versatile and convenient for various needs |

Should Gloves be Worn When Using a Drill?

Worried about hand injuries while drilling?

Wearing gloves when using a drill can protect your hands from sharp edges and debris. It also provides a better grip, enhancing control and safety.

Let’s explore the importance of gloves in drilling tasks.

The Importance of Hand Protection

When operating a drill, especially with step drill bits, your hands are at risk of coming into contact with sharp edges, metal shards, or other debris. Gloves2 act as a barrier, reducing the chance of cuts, abrasions, and other injuries. Additionally, gloves can protect your hands from the vibration and heat generated during drilling, preventing long-term discomfort and potential nerve damage.

Enhancing Grip and Control

Gloves not only protect your hands but also improve your grip on the drill. A secure grip is crucial for maintaining control, ensuring precision, and preventing accidental slips that could lead to injuries or damaged materials. Choosing gloves with non-slip materials can make a significant difference in handling the drill effectively.

Selecting the Right Gloves

When selecting gloves for drilling, consider the following:

- Material: Look for gloves made of durable materials like leather or heavy-duty synthetic fabrics that offer protection without sacrificing flexibility.

- Fit: Gloves should fit snugly to provide maximum control and dexterity.

- Grip Features: Textured palms or rubberized coatings can enhance grip, especially when handling wet or oily materials.

Table: Recommended Gloves for Drilling

| Glove Type | Features |

|---|---|

| Leather Gloves | Durable, excellent protection against sharp edges |

| Synthetic Gloves | Flexible, lightweight, good for dexterity |

| Rubberized Gloves | Enhanced grip, suitable for slippery conditions |

When and How to Use Step Drill Bits: A Detailed Guide

Unsure when to choose a step drill bit over other types?

Step drill bits are ideal for creating multiple hole sizes in thin materials efficiently. They excel in applications requiring precision and versatility.

Dive into the specifics of using step drill bits effectively.

Selecting the Right Step Drill Bit

Choosing the appropriate step drill bit depends on several factors:

- Material: Ensure the bit is suitable for the material you’re drilling, whether it’s metal, plastic, or wood.

- Size Requirements: Determine the range of hole sizes you need. Step drill bits come in various sizes, so select one that covers your requirements.

- Drill Compatibility3: Verify that the step drill bit is compatible with your drill’s chuck size and power.

Preparing for Drilling

Before you begin, prepare your workspace:

- Secure the Material: Use clamps or a vise to hold the material firmly in place, preventing movement during drilling.

- Mark the Hole Location: Use a center punch or marker to indicate where you want to drill, ensuring accuracy.

- Select the Appropriate Step: Start with the smallest step if you’re unsure of the required hole size, gradually moving to larger steps as needed.

Drilling Techniques

Follow these steps for effective drilling:

- Start Slow: Begin drilling at a low speed to create a guide hole, which helps maintain accuracy.

- Apply Even Pressure: Use steady, moderate pressure to prevent the bit from slipping or causing damage.

- Increase Speed Gradually: As the bit penetrates the material, you can increase the drill speed for efficiency.

- Clear Debris: Periodically remove the bit from the hole to clear out debris, ensuring a clean cut and preventing overheating.

Maintaining Your Step Drill Bits

Proper maintenance extends the life of your step drill bits:

- Clean After Use: Remove any debris or residue from the bit after each use.

- Sharpen Regularly: Sharpen the cutting edges to maintain precision and efficiency.

- Store Properly: Keep the bits in a dry, secure place to prevent rust and damage.

H3: Common Mistakes to Avoid

Avoid these common errors when using step drill bits:

- Using Excessive Force: Applying too much pressure can cause the bit to overheat or break.

- Drilling at High Speeds: High speeds can lead to inaccurate holes and increased wear on the bit.

- Neglecting Maintenance: Failing to clean and sharpen the bits reduces their effectiveness and lifespan.

H3: Advantages Over Traditional Drill Bits

Step drill bits offer several advantages compared to traditional drill bits:

- Versatility: One bit can handle multiple hole sizes, reducing the need for a large set of bits.

- Efficiency: Faster hole creation without frequent bit changes saves time on projects.

- Precision: The stepped design ensures clean, accurate holes with minimal effort.

Table: Step Drill Bits vs. Traditional Drill Bits

| Feature | Step Drill Bits | Traditional Drill Bits |

|---|---|---|

| Versatility | High – multiple hole sizes | Low – one hole size per bit |

| Efficiency | Faster – no bit changes needed | Slower – frequent bit changes |

| Precision | High – clean, accurate holes | Variable – depends on bit quality |

| Suitable Materials | Thin metals, plastics, wood | All materials with specific bits |

What Is the Advantage of a Step Drill Bit?

Looking for a more efficient drilling solution?

Step drill bits offer unmatched versatility and precision for various drilling tasks. They streamline the drilling process, making it faster and more accurate.

Explore the key benefits that make step drill bits a valuable tool.

Versatility in Hole Sizes

One of the primary advantages of step drill bits is their ability to create multiple hole sizes with a single bit. Each step on the bit corresponds to a different diameter, allowing you to drill a range of hole sizes without changing bits. This versatility is especially beneficial in projects requiring various hole sizes, reducing the need for a complete set of drill bits and simplifying the tool selection4 process.

Efficiency and Time-Saving

Using a step drill bit significantly speeds up the drilling process. Instead of stopping to switch bits for different hole sizes, you can quickly adjust the drill to the desired step. This continuous workflow minimizes downtime and enhances productivity, making step drill bits ideal for both professional and DIY applications where time is of the essence.

Precision and Clean Cuts

Step drill bits are designed to produce clean, precise holes with minimal effort. The stepped design ensures that each hole size is consistently accurate, reducing the likelihood of overshooting or undershooting the desired diameter. This precision is crucial in applications like electrical installations and metal fabrication, where exact hole dimensions are essential for proper fit and functionality.

Cost-Effectiveness

Investing in step drill bits can be more cost-effective in the long run. By eliminating the need for multiple drill bits to achieve different hole sizes, you save money on purchasing and maintaining a large bit collection. Additionally, the durability and longevity of quality step drill bits mean fewer replacements and lower overall costs.

Ease of Use

Step drill bits are user-friendly, making them accessible to both beginners and experienced drillers. The intuitive design allows for easy size adjustments without the need for specialized knowledge or skills. This ease of use makes step drill bits a popular choice for a wide range of users, from hobbyists to professional tradespeople.

H3: Durability and Longevity

High-quality step drill bits are built to last. Made from durable materials like high-speed steel (HSS) or cobalt, they can withstand repeated use and resist wear and tear. This durability ensures that the bits maintain their sharpness and effectiveness over time, providing reliable performance even in demanding applications.

H3: Space-Saving Design

The compact, all-in-one nature of step drill bits means they take up less space in your toolkit. Instead of carrying multiple bits for different hole sizes, a single step drill bit can handle a variety of tasks, freeing up space and reducing clutter. This space-saving advantage is particularly beneficial for professionals who need to manage their tools efficiently.

Table: Advantages of Step Drill Bits

| Advantage | Description |

|---|---|

| Versatility | Multiple hole sizes with one bit |

| Efficiency | Faster drilling without bit changes |

| Precision | Clean, accurate holes |

| Cost-Effectiveness | Saves money on purchasing multiple bits |

| Ease of Use | User-friendly design suitable for all skill levels |

| Durability | Long-lasting performance with high-quality materials |

| Space-Saving | Reduces toolkit clutter with a single versatile bit |

Conclusion

Step drill bits simplify drilling with versatility and precision.

-

The conical shape is a key feature of step drill bits. ↩

-

The keyword "gloves" is directly related to safety gear for drilling. ↩

-

Ensuring drill bit compatibility with the chuck size is vital to avoid issues during the drilling process. ↩

-

Tool selection is crucial in understanding how step drill bits fit into a broader project. ↩