Is More Teeth on a Circular Saw Blade Better?

Circular saw blades come in various types, sizes, and teeth configurations. The question often arises: is more teeth on a circular saw blade really better? It’s a valid concern, especially when trying to make the right choice for your cutting needs.

The number of teeth on a circular saw blade plays a significant role in the quality and speed of the cut. More teeth generally provide finer, smoother cuts, but they also come with trade-offs. More teeth can lead to slower cutting speeds and more heat buildup, which can wear down the blade faster. Understanding how to balance blade teeth count with your cutting material is crucial for making the right choice.

Before we dive deeper into this, let’s explore some other commonly asked questions surrounding circular saw blades.

Best Circular Saw Blade for Particle Board?

When cutting particle board, you want a blade that minimizes chipping and provides a smooth, clean edge.

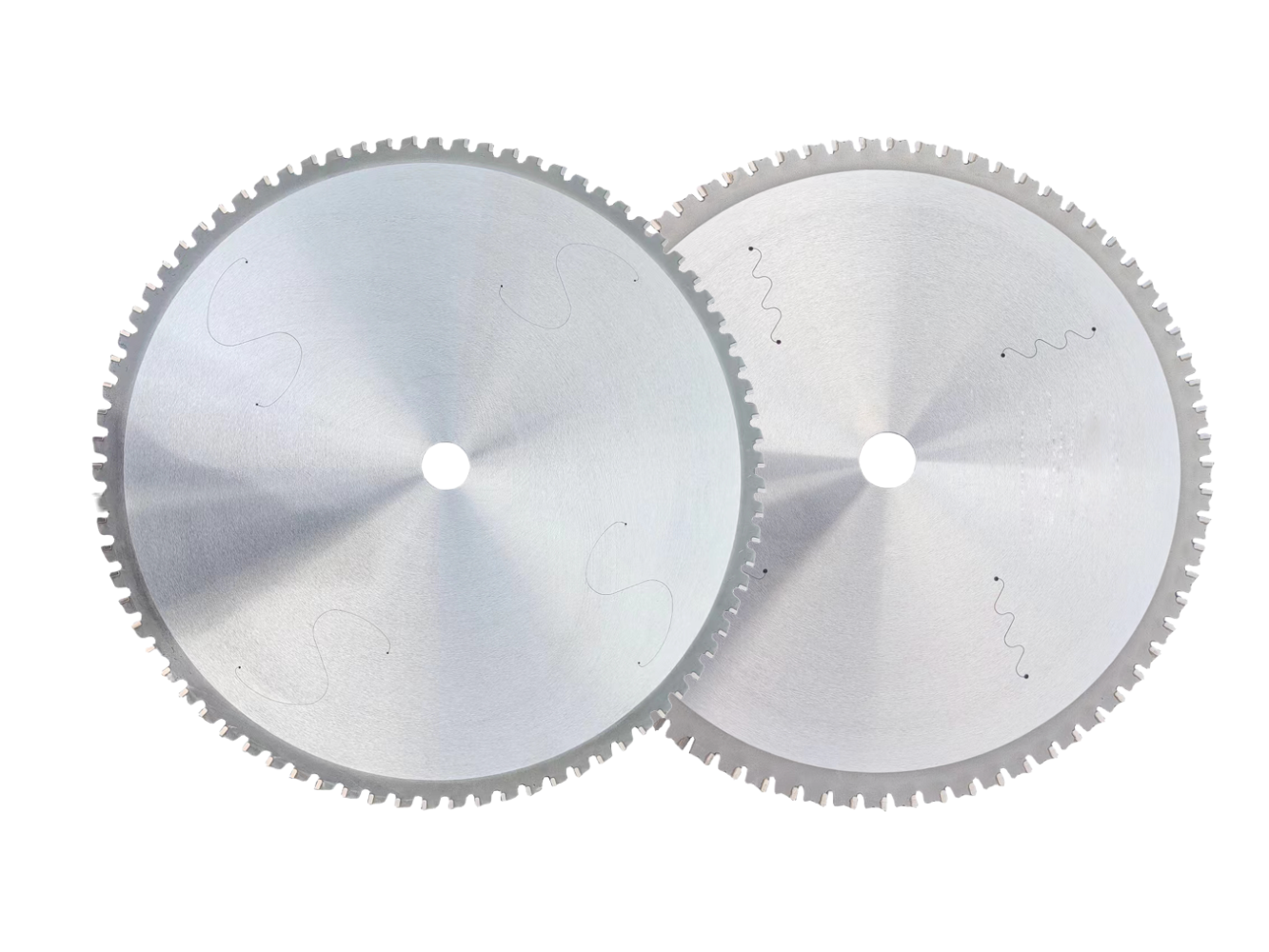

A high tooth count blade with a fine-tooth configuration works best for cutting particle board. These blades reduce the risk of damaging the material, providing a clean and precise cut.

Why Fine Teeth Matter for Particle Board

Particle board is a composite material, made of compressed wood fibers and resin, which can easily chip if not cut properly. For this reason, a circular saw blade1 with a higher tooth count (around 80 to 100 teeth for 7 1/4-inch blades) is ideal for clean cuts. A fine-tooth blade ensures that each cut is smooth without splintering the edges.

Blade Type Considerations

- Carbide-Tipped Blades: These are ideal for particle board. The carbide tips resist wear and maintain their sharpness longer than standard steel blades.

- ATB (Alternate Top Bevel): This tooth geometry ensures smooth cuts in materials like particle board by offering a fine cut while minimizing edge damage.

Choosing the right blade for particle board can make all the difference in the final outcome of your project. With the right saw blade, you’ll achieve the precision and quality you’re after.

Can You Cut Aluminum with a Wood Blade?

Cutting aluminum with a wood blade may seem like an easy shortcut, but it’s not ideal.

While a wood blade can technically cut aluminum, it isn’t the best tool for the job. A dedicated aluminum-cutting blade is designed with specific features to handle the softness and heat buildup that comes with cutting metal.

The Issues with Cutting Aluminum Using a Wood Blade

A wood blade is made with teeth designed for cutting through wood, and using it to cut metal like aluminum2 presents several challenges. Wood blades are typically made with standard carbide or steel teeth, which are not optimal for cutting metal. As you cut aluminum, you’ll notice the blade struggling to make smooth cuts, and it may overheat or dull much quicker.

Aluminum is softer than wood, but the material still requires a specialized blade to avoid excessive wear and potential damage to both the blade and the material. Using the wrong blade may cause the metal to bend or melt at the edges due to friction, leading to a poor-quality cut.

How to Properly Cut Aluminum

To cut aluminum properly, use a blade designed for the purpose. Aluminum-cutting blades feature a higher tooth count, often with a special tooth geometry that’s optimized for metal cutting. These blades are usually made with more durable materials, such as carbide, to withstand the unique demands of cutting metal.

Is it Ok to Cut Aluminum with a Miter Saw?

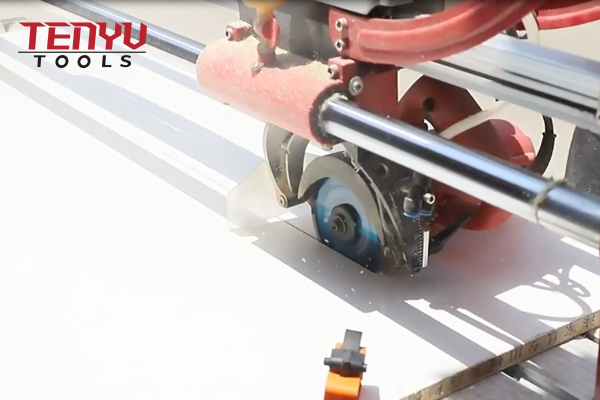

When cutting aluminum, using the right saw is just as important as using the right blade. A miter saw can indeed be used for cutting aluminum, but there are some important things to keep in mind.

It is okay to cut aluminum with a miter saw, but you must ensure you are using the correct blade and settings. Miter saws offer excellent precision for cutting aluminum at various angles, but using a wood blade could lead to unsatisfactory results.

Things to Consider When Using a Miter Saw for Aluminum

When using a miter saw to cut aluminum, it’s essential to make sure the blade is specifically designed for metal. The wrong blade will not only result in a poor cut but could also damage your saw. A dedicated aluminum blade typically has fewer teeth than a wood blade, but they are wider and have a tougher material, like carbide, for durability.

The RPM of the saw3 should also be adjusted when cutting metal. A miter saw typically runs faster for wood cutting, so reducing the speed when cutting aluminum will help reduce heat and friction buildup, which can lead to blade damage or a poor cut quality.

Recommended Blades for Miter Saws

- Carbide-Tipped Blades: These blades have a durable edge that’s perfect for cutting through metals like aluminum.

- Triple Chip Grind (TCG): This tooth configuration provides clean, sharp cuts in aluminum by reducing heat buildup.

Safety Considerations

Cutting aluminum can generate small metal shards or sharp edges, so it’s important to wear proper safety gear, including goggles, gloves, and a mask.

Cutting Aluminum on a Table Saw?

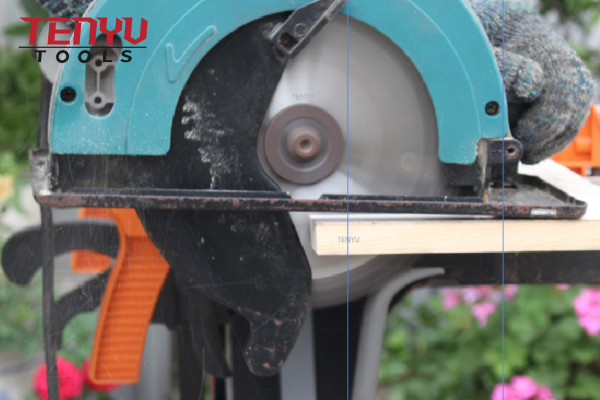

Just like a miter saw, a table saw can also be used to cut aluminum, but there are specific precautions and settings to keep in mind.

A table saw can cut aluminum, but you must use a blade made specifically for metal, and adjust the saw’s speed and feed rate. Cutting aluminum on a table saw without these precautions can lead to overheating, poor cuts, and even damage to both the material and the saw itself.

Why the Right Blade Matters for Cutting Aluminum

For aluminum, a table saw blade needs to be designed with tougher materials like carbide4. You also want the teeth to be set at the right angle for a clean cut through the metal. Using a wood blade could result in overheating, while a specialized aluminum blade ensures smooth cutting action and minimizes heat buildup.

Blade Features for Aluminum Cutting

When cutting aluminum on a table saw, you want a blade with the following features:

- Carbide-Tipped Teeth: Carbide tips resist heat and maintain sharpness longer than standard steel blades.

- Low Teeth Count: Blades designed for cutting metal typically have fewer teeth than wood blades. A lower tooth count helps to reduce heat buildup and prevents the blade from getting bogged down by the softness of the material.

Tips for Cutting Aluminum on a Table Saw

- Feed Rate: Don’t force the material through the blade. Allow the blade to cut at its own pace.

- Lubrication: Using a lubricant can help reduce friction and keep the blade cool.

- Adjusting Blade Height: Set the blade so it only cuts through the thickness of the aluminum. Don’t expose too much of the blade, as this can cause unnecessary friction and heat.

Conclusion

Choosing the right circular saw blade, and using the correct equipment for cutting aluminum or particle board, is key to achieving the best results. Understanding the importance of blade type, teeth count, and cutting technique ensures smooth, precise cuts every time.

-

"circular saw blade" is directly related to choosing the right blade for cutting particle board without splintering. ↩

-

"aluminum", points to the core issue of using a wood blade on aluminum. ↩

-

"RPM of the saw" deserves a link because it’s a critical aspect of proper technique when using a miter saw to cut metal. ↩

-

This link connects to information about why carbide is specifically used in table saw blades. ↩