Have you ever needed a perfect square hole but struggled with standard drill bits?

Yes, there are specialized drill bits designed to cut square holes efficiently and accurately.

Square holes can be challenging, but the right tools make all the difference. Let’s explore how you can achieve precise square holes in your projects.

How Do You Drill a Perfect Square Hole?

Ever struggled to get sharp corners with round holes?

Drilling a perfect square hole involves using specialized bits that combine drilling and chiseling actions to shape the hole accurately.

Creating a perfect square hole requires more than just a standard drill bit. It involves a combination of drilling and chiseling to achieve the desired shape. First, a round hole is drilled using an auger bit, which removes the bulk of the material. Then, a square chisel is used to cut the corners of the hole, transforming it into a square shape. This process ensures that the edges are clean and precise, which is essential for tasks like creating mortise and tenon joints in woodworking.

Step-by-Step Process

- Drill the Round Hole: Start by drilling a round hole with an auger bit1 to the desired depth.

- Chisel the Corners: Use a square chisel to carefully cut the corners of the round hole.

- Refine the Shape: Smooth out any rough edges to ensure the hole is perfectly square.

Tips for Success

- Use a Drill Press: For better alignment and stability.

- Secure the Workpiece: Prevents movement during drilling and chiseling.

- Regular Maintenance: Keep your bits sharp and clean for the best results.

By following these steps, you can achieve a perfect square hole that meets your project’s requirements.

What are Square Drill Bits Called?

Confused by the different names of drill bits?

Square drill bits are commonly referred to as mortise drill bits or square hole drill bits.

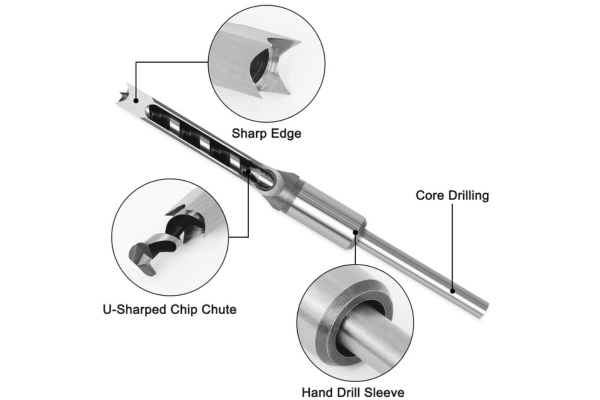

Square drill bits come in various types, each designed for specific applications. The most common type is the mortise drill bit, which consists of an auger bit and a square chisel. These bits are primarily used in woodworking for creating precise square holes needed in mortise and tenon joints. Another name you might encounter is the square hole drill bit, which emphasizes its ability to produce square-shaped holes. Understanding the terminology can help you select the right tool for your project and communicate effectively with suppliers or colleagues.

Types of Square Drill Bits

| Type | Description | Common Use |

|---|---|---|

| Mortise Drill Bit | Combines an auger bit with a square chisel | Mortise and tenon joints |

| Square Hole Bit | Specifically designed to create square-shaped holes | Precision woodworking projects |

Choosing the Right Bit

When selecting a square drill bit2, consider the size and the material you are working with. Mortise drill bits are versatile and suitable for most woodworking tasks, while specialized square hole bits may be better for intricate designs. Always ensure that the bit is compatible with your drilling equipment to achieve the best results.

Can I Use a Mortising Bit In a Drill Press?

Wondering if your drill press can handle a mortising bit?

Yes, mortising bits are designed to be used with drill presses, providing the stability needed for accurate square holes.

Using a mortising bit in a drill press is highly recommended for achieving precise square holes. Drill presses offer the necessary stability and alignment, ensuring that the mortising bit operates correctly without wobbling or misalignment. This setup allows the auger bit and square chisel to work together seamlessly, cutting clean and accurate square holes. When using a drill press, it’s essential to secure your workpiece firmly and adjust the press to the correct depth to prevent overdrilling or chisel jamming. Additionally, regular maintenance of both the drill press and the mortising bit will ensure consistent performance and longevity of your tools.

Advantages of Using a Drill Press

- Stability: Reduces the risk of misalignment3.

- Precision: Allows for accurate depth control.

- Ease of Use: Simplifies the drilling and chiseling process.

Best Practices

- Secure the Workpiece: Use clamps to hold the material steady.

- Adjust Depth Settings: Prevents overdrilling and ensures consistent hole depth.

- Maintain Equipment: Keep the drill press and bits clean and sharp.

By utilizing a drill press with a mortising bit, you can achieve professional-quality square holes with ease and efficiency.

Can You Use a Square Hole Drill Bit In a Hand Drill?

Thinking of using a square hole drill bit with your hand drill?

While possible, using a square hole drill bit in a hand drill is not recommended due to alignment and stability issues.

Square hole drill bits, such as mortising bits, require precise alignment and stability to function correctly. Hand drills lack the rigidity and consistent control provided by drill presses or mortising machines. This instability can lead to misaligned holes, chisel jamming, and uneven cuts, making it difficult to achieve the desired square shape. Additionally, hand drilling does not offer the same depth control, increasing the risk of overdrilling or damaging the workpiece. For best results, it’s advisable to use a drill press or a mortising machine when working with square hole drill bits. If a hand drill is your only option, ensure that you have a steady hand and consider using guides to improve alignment, though the outcome may still fall short of the precision achieved with more stable equipment.

Challenges with Hand Drills

- Lack of Stability: Increases the risk of misalignment.

- Inconsistent Depth Control4: Makes it harder to achieve uniform hole depth.

- Increased Effort: Requires more physical effort to maintain control.

Possible Solutions

- Use a Drill Guide: Helps maintain alignment.

- Secure the Workpiece: Prevents movement during drilling.

- Go Slow: Reduces the chance of chisel jamming.

While using a hand drill for square holes is possible, the limitations make it less ideal compared to using specialized equipment.

How to Drill a Straight Hole?

Struggling to keep your holes straight and true?

Drilling a straight hole requires proper alignment, the right tools, and steady hands to ensure accuracy.

Drilling a straight hole is essential for many woodworking and construction projects. To achieve a straight hole, start by marking the exact spot where you want to drill. Use a drill guide or a jig to help maintain the correct angle and alignment. A drill press is ideal for this task, as it provides stability and precise control over the drilling angle. If using a hand drill, ensure that you hold it firmly and perpendicular to the workpiece. Additionally, using sharp drill bits and maintaining a steady speed can help prevent the bit from wandering, resulting in a cleaner and straighter hole. Practicing on scrap material before working on your actual project can also help improve your technique and ensure better results.

Tools for Drilling Straight Holes

- Drill Press5: Offers the most control and precision.

- Drill Guides: Assist in maintaining the correct angle.

- Hand Drill with Steady Grip: Necessary if a drill press is unavailable.

Techniques for Precision

- Marking the Spot: Ensures accurate placement.

- Using a Center Punch: Creates a guide for the drill bit.

- Maintaining Consistent Pressure: Prevents the drill bit from bending.

By implementing these strategies, you can consistently drill straight holes that meet your project’s requirements.

How to Drill a Hole Square Without a Drill Press?

Need to drill a square hole but don’t have a drill press?

You can drill a square hole without a drill press by using a mortising machine or handheld jigs to guide the square chisel accurately.

Drilling a square hole without a drill press is challenging but achievable with the right tools and techniques. One method is to use a mortising machine, which provides the necessary stability and alignment similar to a drill press. If a mortising machine is not available, handheld jigs can be used to guide the square chisel, helping to maintain the correct angle and prevent misalignment. Another option is to use a drill guide to stabilize the hand drill, allowing for more precise control over the drilling process. Additionally, securing the workpiece firmly and working slowly can help reduce the risk of chisel jamming and ensure a cleaner, more accurate square hole. While these methods may require more effort and practice, they can produce satisfactory results for projects that do not demand the highest level of precision.

Alternative Tools and Methods

- Mortising Machine: Provides stability and precision.

- Handheld Jigs: Assist in guiding the chisel.

- Drill Guides6: Improve alignment for handheld drills.

Tips for Success

- Secure Your Workpiece: Prevents movement during drilling.

- Use Sharp Bits and Chisels: Ensures cleaner cuts.

- Take Your Time: Reduces the risk of errors and misalignment.

With patience and the right approach, you can effectively drill square holes without a drill press.

Which Tool can Make a Square Hole in Wood?

Looking for the perfect tool to make square holes in wood?

A mortising machine or a specialized square hole drill bit used with a drill press is the best tool for making square holes in wood.

To create square holes in wood, the most effective tools are mortising machines and drill presses equipped with square hole drill bits. A mortising machine combines the functionality of an auger bit and a square chisel, allowing for precise and efficient cutting of square holes. Drill presses, when paired with square hole drill bits, provide the necessary stability and alignment to achieve clean and accurate shapes. These tools are essential for tasks such as creating mortise and tenon joints, installing hardware, and other woodworking applications that require square holes. Additionally, some handheld jigs and drill guides can be used with specialized bits to create square holes, though they may not offer the same level of precision as dedicated machines.

Recommended Tools

- Mortising Machine7: Ideal for high-precision square holes.

- Drill Press with Square Hole Bit: Versatile and reliable.

- Handheld Jigs and Guides: Suitable for smaller projects or when specialized equipment is unavailable.

Choosing the Right Tool

Consider the scale and precision required for your project when selecting a tool. For professional-grade work, a mortising machine or drill press is recommended. For DIY projects or occasional use, handheld jigs and guides can be effective alternatives.

By selecting the appropriate tool, you can efficiently create square holes that meet your woodworking needs.

Conclusion

Square hole drill bits are essential for precise woodworking projects, offering efficiency and consistency.

-

refers to a specific tool used in drilling round holes. ↩

-

a specific type of drill bit that creates square-shaped holes. ↩

-

cause issues in various engineering processes. ↩

-

a key concept in precision machining and manufacturing. ↩

-

relevant to precision drilling. ↩

-

provides further details about how these tools assist in achieving better alignment when using handheld drills. ↩

-

relates to a specific woodworking tool designed to create square or rectangular holes, often for joining pieces of wood. ↩