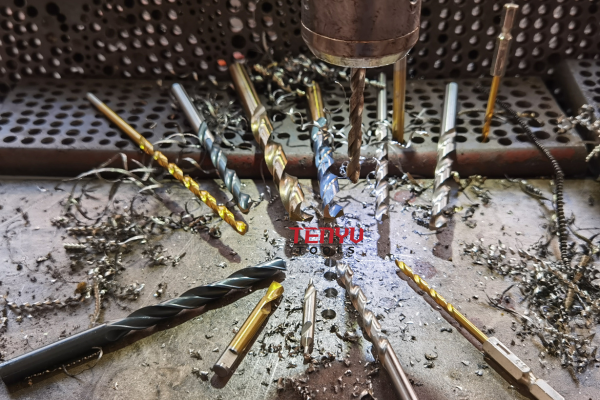

Have you ever wondered what makes drill bits so effective? The materials they’re made of play a crucial role.

Drill bits are primarily made from high-speed steel (HSS), cobalt, or carbide, each offering unique strengths and applications.

Understanding these materials can help you choose the right drill bit for your needs.

What Is the Difference Between HSS and Carbide Tools?

Struggling to decide between HSS and carbide tools? You’re not alone.

HSS tools are more flexible and less brittle, while carbide tools are harder and more wear-resistant, making them suitable for tougher materials.

Choosing between them depends on the specific requirements of your project.

HSS vs Carbide: Key Differences

When selecting between High-Speed Steel (HSS) and carbide tools, it’s essential to understand their distinct properties:

| Feature | High-Speed Steel (HSS) | Carbide |

|---|---|---|

| Hardness | Moderately hard | Extremely hard |

| Flexibility | High | Low |

| Wear Resistance | Moderate | Very high |

| Cost | Generally cheaper | More expensive |

| Applications | General purpose | High-precision and heavy-duty tasks |

HSS tools are favored for their flexibility, making them less likely to break under stress. This property is particularly useful when drilling into materials that require some give, such as wood or certain metals. On the other hand, carbide tools1 excel in cutting through very hard materials like stainless steel or hardened alloys due to their superior hardness and wear resistance. However, this makes them more brittle and prone to chipping if not used correctly. Cost is another factor; HSS tools are generally more affordable, making them a popular choice for everyday use, while carbide tools are a better investment for specialized tasks that demand high precision and durability.

Choosing the right material for your drill bits can significantly impact the efficiency and quality of your work. HSS offers versatility and affordability, making it suitable for a wide range of applications. Carbide, although pricier, provides unmatched performance in demanding environments where longevity and precision are paramount. Assessing the nature of your projects will guide you in selecting the most appropriate drill bit material.

Is Carbon steel Better Than High-Speed Steel for Drill Bits?

Confused about carbon steel versus high-speed steel for drill bits? It’s a common dilemma.

High-Speed Steel (HSS) outperforms carbon steel in terms of hardness, heat resistance, and durability, making it the preferred choice for drill bits.

Understanding their differences can help you make informed decisions for your tools.

Carbon Steel vs High-Speed Steel: A Comparison

Carbon steel and High-Speed Steel (HSS) are two prevalent materials used in manufacturing drill bits, each with its advantages and limitations.

| Feature | Carbon Steel | High-Speed Steel (HSS) |

|---|---|---|

| Hardness | Lower than HSS | Higher |

| Heat Resistance | Poor | Excellent |

| Durability | Less durable | More durable |

| Cost | Generally cheaper | Slightly more expensive |

| Applications | Light-duty tasks | Heavy-duty and high-precision tasks |

Carbon steel drill bits are typically used for light-duty applications where extreme hardness and heat resistance are not required. They are more affordable but lack the durability and performance of HSS drill bits2. Carbon steel is prone to wear and deformation under high temperatures, making it unsuitable for drilling hard materials or prolonged use.

High-Speed Steel, on the other hand, is renowned for its superior hardness and excellent heat resistance. These properties make HSS drill bits ideal for drilling into tougher materials like metal, stainless steel, and other hard substances. The enhanced durability of HSS ensures a longer lifespan and consistent performance, even under demanding conditions. While HSS drill bits are slightly more expensive than their carbon steel counterparts, the investment pays off through their extended usability and efficiency in various applications.

When deciding between carbon steel and HSS drill bits, consider the nature of your projects. For occasional, light-duty tasks, carbon steel may suffice. However, for frequent use, especially involving hard materials, HSS is the superior choice due to its durability and performance.

Difference Between HSS and Cobalt Drill Bits

Can’t decide between HSS and cobalt drill bits? It’s a tough choice many face.

Cobalt drill bits contain a higher percentage of cobalt, enhancing their heat resistance and durability compared to standard HSS bits, making them ideal for drilling harder materials.

Let’s explore their unique characteristics and applications.

HSS vs Cobalt: Detailed Insights

High-Speed Steel (HSS) and cobalt drill bits are both popular choices, each offering distinct advantages for different drilling needs.

| Feature | High-Speed Steel (HSS) | Cobalt Drill Bits |

|---|---|---|

| Cobalt Content | 0% | 5-8% |

| Heat Resistance | Good | Excellent |

| Durability | High | Very high |

| Flexibility | More flexible | Less flexible |

| Cost | Moderate | Higher |

| Best For | General-purpose drilling | Harder materials like stainless steel and titanium |

Cobalt drill bits are essentially an enhanced version of HSS bits, with added cobalt content. This addition significantly improves their heat resistance, allowing them to maintain their hardness and cutting ability at higher temperatures. As a result, cobalt drill bits are exceptionally durable and suitable for drilling into harder materials such as stainless steel, titanium3, and other alloys that would quickly wear out standard HSS bits.

While HSS drill bits are versatile and cost-effective for a wide range of applications, cobalt drill bits excel in specialized tasks that demand higher performance and longevity. The increased brittleness of cobalt bits compared to HSS means they are less flexible, which can be a drawback in certain drilling scenarios but is often outweighed by their superior durability and heat resistance in heavy-duty applications.

Investing in cobalt drill bits is beneficial for professionals and enthusiasts who frequently work with challenging materials. The initial higher cost is offset by their extended lifespan and consistent performance, reducing the need for frequent replacements and ensuring high-quality results in demanding projects.

HSS vs Cobalt vs Carbide Drill Bits: What To Choose

Overwhelmed by the choices between HSS, cobalt, and carbide drill bits? You’re not alone.

HSS offers versatility, cobalt provides enhanced durability for hard materials, and carbide delivers maximum hardness for the toughest drilling tasks. Choose based on your specific material and project requirements.

Let’s break down which option suits your needs best.

Comparing HSS, Cobalt, and Carbide Drill Bits

Selecting the right drill bit material is crucial for achieving optimal performance and longevity. Here’s a comprehensive comparison of HSS, cobalt, and carbide drill bits:

| Feature | High-Speed Steel (HSS) | Cobalt Drill Bits | Carbide Drill Bits |

|---|---|---|---|

| Hardness | Moderate | High | Very High |

| Heat Resistance | Good | Excellent | Excellent |

| Durability | High | Very High | Extremely High |

| Flexibility | More flexible | Less flexible | Least flexible |

| Cost | Most affordable | Mid-range | Most expensive |

| Best For | General-purpose drilling | Hard metals like stainless steel | Extremely hard materials and precision tasks |

| Longevity | Good | Very Good | Excellent |

High-Speed Steel (HSS) drill bits are ideal for general-purpose drilling4. They offer a good balance between performance and cost, making them suitable for a wide range of materials including wood, plastic, and some metals. Their versatility makes them a staple in both professional and DIY toolkits.

Cobalt drill bits take durability a step further with added cobalt content, enhancing their ability to withstand higher temperatures and resist wear when drilling into tougher materials like stainless steel and titanium. While they are more expensive than HSS, their extended lifespan and superior performance in challenging applications justify the investment for users who frequently work with hard materials.

Carbide drill bits represent the pinnacle of hardness and precision. They are designed for the most demanding drilling tasks, such as machining extremely hard materials like carbide itself, ceramics, and hardened steel. The exceptional hardness of carbide makes these bits incredibly durable and capable of maintaining sharpness over extended use. However, their brittleness requires careful handling to avoid chipping or breaking, and they come at a higher cost compared to HSS and cobalt bits.

When choosing between these options, consider the specific demands of your projects. For everyday tasks and a broad range of materials, HSS drill bits are a reliable choice. If you often work with tougher metals and need enhanced durability, cobalt drill bits are worth the extra investment. For specialized applications that require maximum hardness and precision, carbide drill bits are the best option despite their higher cost and fragility.

Cobalt Drill Bits vs High Speed Steel (HSS) Drill Bits

Not sure whether to go with cobalt or HSS drill bits? It’s a common question.

Cobalt drill bits are designed for high-temperature applications and harder materials, while HSS drill bits are versatile and cost-effective for general use.

Let’s delve into their specific advantages and use cases.

In-Depth Look: Cobalt vs High-Speed Steel Drill Bits

When choosing between cobalt and High-Speed Steel (HSS) drill bits, it’s essential to understand their distinct properties and applications.

| Aspect | Cobalt Drill Bits | High-Speed Steel (HSS) Drill Bits |

|---|---|---|

| Material Composition | HSS with 5-8% cobalt added | Pure High-Speed Steel |

| Hardness | Higher | Moderate |

| Heat Resistance | Superior | Good |

| Durability | Exceptional for hard materials | Good for general purposes |

| Flexibility | Less flexible | More flexible |

| Cost | Higher | Lower |

| Best Applications | Stainless steel, titanium, cast iron | Wood, plastic, general metal drilling |

Cobalt drill bits incorporate a small percentage of cobalt into the HSS, significantly enhancing their hardness and heat resistance. This makes them exceptionally suitable for drilling into hard metals like stainless steel5 and titanium, where standard HSS bits would wear out quickly. The added cobalt allows these bits to maintain their edge and performance even under high-temperature conditions generated by friction during drilling.

On the other hand, High-Speed Steel (HSS) drill bits are made from a pure steel alloy that offers a good balance of hardness and toughness. They are highly versatile and perform well across a variety of materials, including wood, plastic, and general metal drilling. HSS bits are more flexible compared to cobalt bits, reducing the risk of breakage during use. Their affordability makes them a popular choice for everyday drilling tasks where extreme hardness and heat resistance are not required.

However, when it comes to specialized applications involving very hard materials, cobalt drill bits are the superior choice despite their higher cost. The investment in cobalt bits pays off through their extended lifespan and consistent performance in challenging drilling environments. For users who frequently encounter hard metals in their projects, cobalt bits offer unmatched durability and efficiency.

In summary, if your drilling tasks involve a wide range of materials with occasional hard metals, HSS drill bits are a reliable and cost-effective option. Conversely, if your work predominantly involves hard metals and you require drill bits that can withstand high temperatures and resist wear, investing in cobalt drill bits is the better choice.

Conclusion

Choosing the right drill bit material enhances your drilling efficiency and project quality.

-

are highlighted for their superior performance in tough materials. ↩

-

offer increased durability and heat resistance, making them suitable for high-stress applications. ↩

-

is another tough material that cobalt drill bits are well-suited for. ↩

-

refers to the broad category of drilling tasks that High-Speed Steel drill bits are suitable for. ↩

-

specifically mentioned as one of the metals that cobalt drill bits are effective for. ↩