Are your drill bits not performing as they should? It might be time to consider the sharpening angles.

Choosing the right sharpening angle can significantly enhance the performance and lifespan of your drill bits.

Understanding the correct angles ensures efficient drilling and reduces wear and tear.

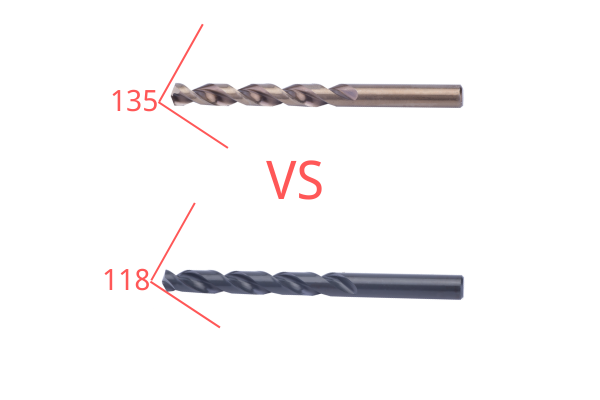

118 vs 135 Drill Bits: Does it matter?

Are you confused about whether to use 118 or 135 drill bits? This decision impacts your drilling efficiency.

Yes, the angle difference between 118 and 135 degrees affects their suitability for different materials and tasks.

Choosing the right angle ensures optimal performance and durability of your drill bits.

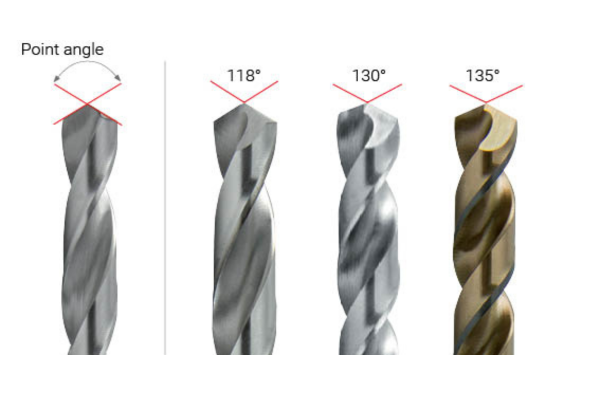

When selecting between 118 and 135-degree drill bits, it’s essential to consider the material you’re working with. The 118-degree bits are standard for most materials, offering a balance between cutting efficiency and durability. They are ideal for drilling into wood, plastics, and metals like aluminum and soft steels. On the other hand, 135-degree drill bits are designed for harder materials, such as stainless steel and cast iron. The steeper angle provides a sharper point, reducing the risk of the bit walking or slipping during drilling. Additionally, the 135-degree angle helps in distributing the cutting forces more evenly, which can prolong the life of the drill bit. For precision tasks, where a clean and accurate hole is crucial, opting for the appropriate angle can make a significant difference. It’s also worth noting that using the wrong angle can lead to increased wear, overheating, and even breakage of the drill bit. Therefore, understanding the specific requirements of your project and the materials involved is key to making an informed decision between 118 and 135-degree drill bits.

Comparison Table

| Feature | 118-Degree Drill Bits | 135-Degree Drill Bits |

|---|---|---|

| Suitable Materials | Wood, Plastics, Soft Metals | Stainless Steel1, Cast Iron |

| Cutting Efficiency | Moderate | High |

| Durability | Good | Excellent |

| Point Sharpness | Standard | Sharper |

| Application Precision | Good | Excellent |

Do You Know the Angle of HSS Drill Bits?

Are you aware of the angles used in High-Speed Steel (HSS) drill bits? Knowing this can improve your drilling tasks.

HSS drill bits typically have angles of 118 or 135 degrees, tailored for specific materials and applications.

Selecting the correct HSS drill bit angle ensures efficient drilling and extends the tool’s lifespan.

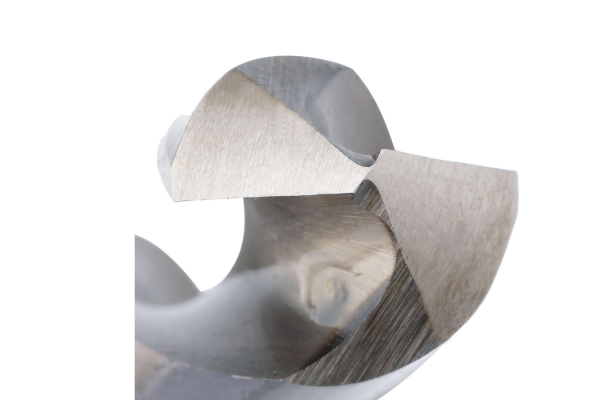

High-Speed Steel (HSS) drill bits are renowned for their versatility and durability, making them a staple in both professional and DIY toolkits. The angle of an HSS drill bit plays a crucial role in determining its performance and suitability for various tasks. The most common angles are 118 degrees and 135 degrees. The 118-degree angle is the standard, making these bits suitable for drilling into softer materials like wood, plastics, and soft metals. This angle offers a good balance between cutting speed and durability. On the other hand, 135-degree HSS drill bits are designed for harder materials such as stainless steel and cast iron. The steeper angle provides a sharper point, reducing the likelihood of the bit wandering or causing inaccuracies during drilling. Additionally, the 135-degree angle helps in distributing the cutting forces more evenly, which enhances the bit’s durability and reduces wear. For specialized applications, there are also HSS drill bits with other angles, such as 90 degrees for creating countersinks or flat-bottomed holes. Understanding the angle of your HSS drill bits and matching them to your specific drilling needs can significantly improve both the quality of your work and the efficiency of your drilling process.

Key Considerations

- Material Type: Choose the angle based on the hardness of the material.

- Drilling Precision2: Steeper angles offer more precision for harder materials.

- Bit Durability: Proper angle selection enhances the lifespan of the drill bit.

- Application Specifics: Specialized angles are available for specific tasks like countersinking.

Which Drill Point Angle Should I Use?

Not sure which drill point angle to choose? The right angle can make your drilling more effective and precise.

The choice of drill point angle depends on the material and the specific drilling requirements of your project.

Selecting the appropriate drill point angle ensures efficient drilling and reduces the risk of damaging materials or the drill bit.

Choosing the correct drill point angle is fundamental to achieving efficient and accurate drilling results. The angle determines how the drill bit interacts with the material, affecting both the speed and quality of the hole. For general-purpose drilling, a 118-degree angle is often recommended. This angle provides a good balance, making it versatile for drilling into wood, plastic, and softer metals. If you’re working with harder materials like stainless steel or cast iron, a 135-degree angle is more suitable. The steeper angle allows for a sharper point, which can penetrate harder surfaces more easily and reduce the likelihood of the bit slipping or walking. Additionally, the type of hole you need to create can influence your choice. For example, if you’re aiming for a countersink or a flat-bottomed hole, you might opt for a drill bit with a specific angle designed for that purpose. It’s also important to consider the speed and feed rate when selecting the angle. A steeper angle may require a slower feed rate to prevent overheating and ensure a clean cut, while a shallower angle might allow for faster drilling but with less precision. Ultimately, understanding the relationship between drill point angle and material properties will help you make informed decisions, leading to better drilling performance and longer-lasting drill bits.

Practical Tips

- Match Angle to Material: Use 118 degrees for softer materials and 135 degrees for harder ones.

- Consider Hole Type3: Choose angles based on whether you need a standard hole or a countersink.

- Adjust Speed and Feed Rate: Steeper angles may require slower drilling speeds.

- Invest in Quality Bits: Higher quality bits maintain their angle better, ensuring consistent performance.

Why Standard Tip Angle Is 118 Degrees?

Ever wondered why the standard drill bit tip angle is 118 degrees? There’s a practical reason behind it.

The 118-degree angle is standard because it offers a balance between cutting efficiency and durability for a wide range of materials.

Understanding why 118 degrees is standard helps in selecting the right drill bit for various applications.

The standard tip angle of 118 degrees has become the industry norm for a reason. This angle provides an optimal balance between cutting performance and durability, making it versatile for a wide range of drilling tasks. A 118-degree angle allows the drill bit to penetrate materials efficiently without excessive force, reducing the risk of the bit overheating or wearing out quickly. This angle is particularly effective for drilling into softer materials like wood, plastics, and soft metals, where a sharper angle might cause the bit to wear out too quickly, and a steeper angle might not provide enough cutting efficiency. Additionally, the 118-degree angle offers better stability and reduces the likelihood of the drill bit wandering or walking during the initial stages of drilling, which is crucial for maintaining accuracy. The widespread adoption of this angle also means that manufacturers can produce drill bits that are compatible with a vast array of tools and applications, ensuring consistency and reliability across different brands and types of drill bits. For professionals and hobbyists alike, the 118-degree standard simplifies the selection process, allowing for easy identification of drill bits suitable for general-purpose use. While there are specialized angles available for specific tasks, the 118-degree angle remains the go-to choice for most drilling needs due to its proven effectiveness and versatility.

Benefits of 118-Degree Angle

- Versatility: Suitable for a wide range of materials.

- Durability: Balances cutting efficiency with bit lifespan.

- Stability4: Reduces bit wandering during drilling.

- Compatibility: Standardized across most tools and applications.

- Ease of Use: Simplifies selection for general-purpose drilling.

When Not to Use 135 Degree Split Points?

Are there situations where a 135-degree split point isn’t the best choice? Knowing when to avoid it can save you time and resources.

Avoid using 135-degree split points when working with softer materials or when precision is paramount, as the angle may cause excessive wear or reduced accuracy.

Understanding the limitations of 135-degree split points ensures you choose the right tool for each task.

While 135-degree split point drill bits offer advantages in drilling hard materials and providing greater accuracy, there are specific scenarios where they may not be the best choice. For instance, when working with softer materials like wood, plastics, or soft metals, the steeper angle can lead to excessive wear on the drill bit. The sharper point of a 135-degree angle might not penetrate these materials as efficiently, resulting in slower drilling speeds and increased heat generation, which can damage both the bit and the material. Additionally, in applications where precision is critical, such as in fine woodworking or detailed metalwork, the 135-degree angle might not provide the level of control needed. The steeper angle can cause the bit to dig too aggressively into the material, leading to inaccuracies in hole placement or depth. Furthermore, 135-degree split points are typically more brittle than their 118-degree counterparts, making them less suitable for tasks that involve impact or side loads, as they are more prone to chipping or breaking under stress. In such cases, a standard 118-degree drill bit would offer better durability and flexibility. It’s also important to consider the type of drill being used; high-speed drills may not provide the necessary torque for 135-degree bits, leading to inefficient drilling and potential damage to the bit. Therefore, while 135-degree split points are excellent for specific applications, recognizing when they are not the ideal choice can help you maintain the quality and efficiency of your projects.

Situations to Avoid 135-Degree Split Points

- Soft Materials5: Less efficient and prone to excessive wear.

- High-Precision Tasks: May cause inaccuracies due to aggressive cutting.

- Impact or Side Loads: Higher risk of chipping or breaking.

- High-Speed Drilling: May not provide sufficient torque, leading to inefficiency.

- General-Purpose Use: Lack of versatility compared to standard angles.

Conclusion

Choosing the right drill bit angle enhances your drilling efficiency and project quality.

-

Stainless steel requires specific types of drill bits due to its hardness. ↩

-

Drilling precision is critical for achieving accurate holes in materials, especially harder ones. ↩

-

The hole type significantly impacts the angle selection, making this a key concept to explore further. ↩

-

Stability is a technical aspect that influences performance in drilling. ↩

-

This keyword is linked because understanding how soft materials behave in manufacturing processes, especially regarding wear and efficiency. ↩