Drilling stainless steel can be challenging. Choosing the right drill bits makes all the difference.

Selecting the best drill bits for stainless steel ensures efficiency and longevity in your projects.

Keep reading to discover the top options and tips for drilling through tough materials.

Can You Put Oil in a Stainless Steel Drill Bit?

Lubrication is key when drilling stainless steel.

Yes, applying oil to a stainless steel drill bit reduces friction and prevents overheating.

Understanding lubrication can enhance your drilling performance.

Using oil when drilling stainless steel is essential for several reasons. Firstly, lubrication reduces the friction between the drill bit and the metal, which helps prevent the bit from overheating. Overheating can cause the drill bit to lose its temper, making it dull more quickly and reducing its effectiveness. Additionally, oil helps to remove metal shavings from the drilling area, which can clog the bit and make drilling more difficult. Applying a suitable cutting oil or lubricant ensures smoother drilling and extends the life of your drill bits. It’s important to choose the right type of oil; for instance, cutting oils specifically designed for metalworking are ideal as they provide better lubrication and cooling compared to general-purpose oils. Regularly applying oil during the drilling process can also improve the accuracy of your holes, as the reduced friction allows for more controlled drilling. In summary, using oil is a simple yet effective way to enhance the performance and longevity of your stainless steel drill bits.

Types of Lubricants

| Lubricant Type | Benefits | Best For |

|---|---|---|

| Cutting Oil | Excellent cooling and lubrication | Heavy-duty drilling |

| WD-40 | Easy to apply, readily available | Light to medium drilling |

| Synthetic Oil1 | Long-lasting lubrication | Precision drilling |

Can You Cut Hardened Steel with a Drill Bit?

Cutting hardened steel requires the right tools and techniques.

Yes, with the appropriate drill bits, you can cut through hardened steel effectively.

Learn how to tackle hardened steel with the best drill bits available.

Drilling into hardened steel is a demanding task that necessitates high-quality drill bits. Hardened steel has a higher resistance to drilling due to its increased hardness and strength, making it essential to use drill bits designed to withstand such materials. Carbide-tipped drill bits are among the best choices for this purpose, as they offer superior hardness and durability compared to standard bits. Additionally, cobalt drill bits are highly recommended because they are specifically engineered to handle tough metals like hardened steel. These bits contain a higher percentage of cobalt, which enhances their heat resistance and toughness, allowing them to maintain their cutting edges longer under high-stress conditions. When drilling hardened steel, it’s crucial to maintain a steady speed and apply consistent pressure to avoid overheating and potential damage to the drill bit. Using cutting fluids or lubricants can further aid in dissipating heat and reducing friction, thereby prolonging the life of your drill bits. Proper technique combined with the right equipment ensures efficient and effective drilling through even the most challenging hardened steel surfaces.

Recommended Drill Bits for Hardened Steel

| Drill Bit Type | Material | Key Feature |

|---|---|---|

| Cobalt Bits2 | High-speed steel with cobalt | Enhanced heat resistance |

| Carbide-Tipped | Carbide coating | Superior hardness and durability |

| Titanium-Coated | Titanium coating | Reduced friction and longer life |

How to Drill Through Hardened Steel Wrenches?

Drilling through hardened steel wrenches demands precision and the right tools.

To drill through hardened steel wrenches, use carbide or cobalt drill bits with proper lubrication and steady pressure.

Follow these steps to successfully drill through hardened steel wrenches.

Drilling through hardened steel wrenches involves several critical steps to ensure a clean and accurate hole without damaging the tool or the drill bit. Start by selecting the appropriate drill bit, such as a carbide-tipped or cobalt drill bit, which can withstand the hardness of the steel. Before you begin drilling, mark the exact spot where the hole is needed to maintain precision. Secure the wrench firmly using a vise or clamp to prevent any movement during the drilling process, which can lead to inaccurate holes or potential injury. Apply a generous amount of cutting fluid or lubricant to the drill bit to reduce friction and dissipate heat, which helps in maintaining the integrity of both the bit and the steel. Begin drilling at a slow speed to create a small indentation, which acts as a guide and prevents the bit from wandering. Gradually increase the speed while applying steady, moderate pressure to allow the drill bit to penetrate the steel smoothly. It is essential to periodically withdraw the bit to clear away metal shavings and reapply lubricant, ensuring continuous cooling and lubrication. Maintaining a consistent drilling speed and pressure will result in a clean hole with minimal wear on the drill bit, making the process efficient and effective.

Drilling Tips for Hardened Steel

- Mark the Spot: Use a center punch3 to create an indentation.

- Secure the Workpiece: Clamp the wrench tightly to prevent movement.

- Use Cutting Fluid: Apply regularly to keep the bit cool.

- Start Slow: Begin at a low speed to guide the bit.

- Increase Speed Gradually: Once the bit is established, speed up.

- Clear Shavings: Periodically remove the bit to clear debris.

- Maintain Steady Pressure: Avoid excessive force to prevent damage.

What Is the Best Angle to Cut Steel With a Drill Bit?

The cutting angle is crucial for effective drilling in steel.

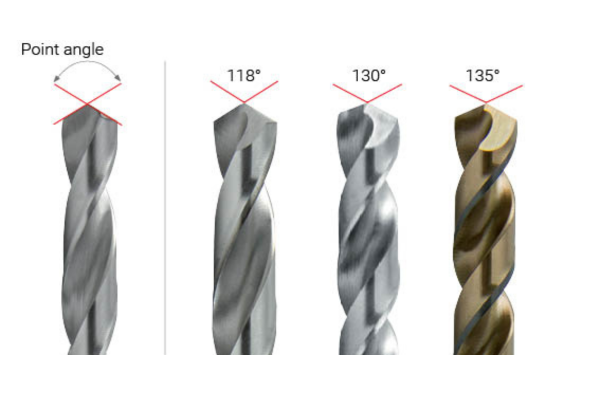

The optimal angle for cutting steel with a drill bit is typically between 118 to 135 degrees, depending on the bit type and steel hardness.

Discover how the cutting angle affects drilling performance and results.

Choosing the right cutting angle when drilling steel significantly impacts the efficiency and quality of the hole. The cutting angle, also known as the lip angle, determines how the drill bit engages with the material. For general-purpose drilling in steel, a standard 118-degree angle is commonly used as it provides a good balance between cutting efficiency and durability. However, when dealing with harder steels or requiring more precision, a higher angle of 135 degrees can be more effective. The steeper angle allows for a sharper cutting edge, which can slice through tougher materials with less effort and generate cleaner holes. Additionally, different types of drill bits may have specific recommended angles; for instance, cobalt and carbide bits often benefit from steeper angles to maximize their hardness and heat resistance properties. Adjusting the cutting angle according to the steel’s hardness and the specific application ensures that the drill bit maintains its cutting edge longer and reduces the likelihood of bit breakage or material deformation. Properly aligning the drill bit at the optimal angle also enhances the accuracy of the hole, making it easier to achieve the desired specifications without excessive wear on the tools.

Optimal Cutting Angles for Different Drill Bits

| Drill Bit Type | Recommended Angle | Best For |

|---|---|---|

| Standard HSS4 | 118 degrees | General-purpose drilling |

| Cobalt Bits | 135 degrees | Harder steels and precision |

| Carbide-Tipped | 135 degrees | Extremely hard materials |

How do I Drill Through 1/2" Steel?

Drilling through 1/2" steel requires power and the right technique.

To drill through 1/2" steel, use a high-quality cobalt or carbide drill bit, apply cutting fluid, and maintain a steady speed and pressure.

Follow these steps for successful drilling through thick steel.

Drilling through 1/2" steel is a task that demands careful preparation and the appropriate tools to ensure success. Begin by selecting a high-quality cobalt or carbide drill bit, as these materials are designed to handle the toughness of thick steel. Before you start drilling, secure the steel piece firmly using a vise or clamps to prevent any movement that could lead to inaccurate drilling or potential accidents. Next, mark the exact location where you need to drill to maintain precision. Apply a generous amount of cutting fluid or lubricant to the drill bit and the drilling area to reduce friction and heat buildup, which can dull the bit and compromise the integrity of the steel. Start drilling at a low speed to create a small pilot hole, which helps guide the bit and prevents it from slipping. Gradually increase the speed while applying steady, moderate pressure to allow the bit to penetrate the steel smoothly. It’s important to periodically withdraw the drill bit to clear away metal shavings and reapply lubricant, ensuring continuous cooling and lubrication throughout the process. Using a drill press with adjustable speed settings can also enhance control and accuracy when drilling through thick steel. By following these steps and maintaining patience, you can effectively drill through 1/2" steel with minimal effort and maximum precision.

Steps to Drill Through 1/2" Steel

- Select the Right Drill Bit5: Cobalt or carbide-tipped.

- Secure the Steel: Use a vise or clamps.

- Mark the Drill Spot: Ensure accuracy with a center punch.

- Apply Cutting Fluid: Lubricate the drilling area.

- Start at Low Speed: Create a pilot hole.

- Increase Speed Gradually: Enhance drilling efficiency.

- Maintain Steady Pressure: Avoid overheating and bit wear.

- Clear Shavings Regularly: Prevent clogging and overheating.

Which Drill do You Use to Drill In Stainless Steel?

Choosing the right drill is essential for effective drilling in stainless steel.

For drilling stainless steel, a drill press or a high-torque cordless drill paired with cobalt or carbide drill bits is ideal.

Learn which drills offer the best performance for stainless steel projects.

When it comes to drilling in stainless steel, the choice of drill plays a pivotal role in achieving precise and clean results. A drill press is often the preferred option for such tasks due to its stability, adjustable speed settings, and ability to maintain a consistent drilling angle. This stability is crucial when working with hard materials like stainless steel, as it minimizes vibrations and ensures a straight, accurate hole. For those who require more flexibility or need to work in various locations, a high-torque cordless drill is a suitable alternative. These drills offer the power needed to penetrate stainless steel, especially when paired with the right type of drill bits. Cobalt and carbide drill bits are highly recommended for stainless steel due to their superior hardness and heat resistance, which prevent dulling and breakage during the drilling process. Additionally, using a drill with a variable speed setting allows for better control over the drilling process, reducing the risk of overheating and extending the lifespan of both the drill and the bits. Whether you choose a drill press or a high-torque cordless drill, ensuring that it is compatible with the high demands of stainless steel drilling will result in more efficient and effective outcomes for your projects.

Recommended Drills for Stainless Steel

| Drill Type | Features | Best For |

|---|---|---|

| Drill Press6 | Stable base, adjustable speeds | Precision and heavy-duty tasks |

| High-Torque Cordless | Portability, high power | Versatile and on-the-go projects |

| Hammer Drill | Percussion action (for some models) | Drilling into tough materials |

Conclusion

Choosing the right drill bits and techniques ensures successful drilling in stainless steel.

-

often used in precision drilling due to its long-lasting lubrication. ↩

-

known for their enhanced heat resistance due to the cobalt alloy mixed with high-speed steel. ↩

-

refers to a tool used to create a small indentation, typically to guide a drill bit. ↩

-

refers to High-Speed Steel drill bits, which are widely used for general-purpose drilling. ↩

-

Carbide-tipped drill bits are often recommended for drilling hard metals. ↩

-

refers to a specific type of power tool that is particularly known for its precision and stability in heavy-duty tasks. ↩