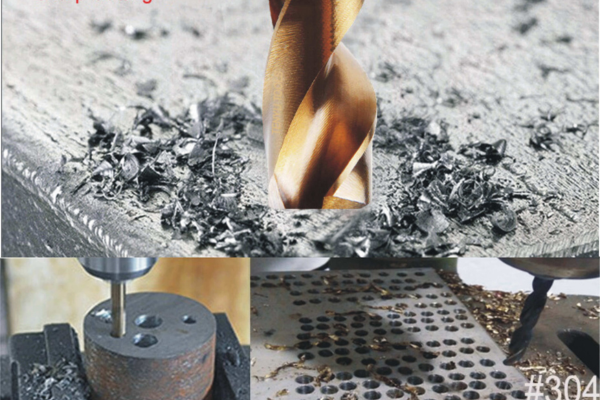

Struggling to find the right drill bit? Titanium drill bits might be the solution you need.

Titanium drill bits are used for drilling into tough materials like metal, wood, and plastic, offering enhanced durability and longer life.

Keep reading to discover why these drill bits are a favorite among professionals and DIY enthusiasts alike.

What are Titanium Drill Bits Used for?

Ever hit a wall with your drill bit? Titanium drill bits can change that.

Titanium drill bits are versatile tools designed for drilling into various materials, including metal, wood, and plastic, with ease and precision.

Understanding the specific uses of titanium drill bits can help you choose the right tool for your projects.

Versatility in Materials

Titanium drill bits are renowned for their ability to handle different materials. Whether you’re working with hard metals like stainless steel or softer materials like wood and plastic, these bits maintain their sharpness and efficiency. Their titanium coating1 reduces friction, allowing for smoother drilling and less wear and tear on the bit itself.

Durability and Longevity

One of the standout features of titanium drill bits is their durability. The titanium coating enhances the bit’s hardness, making it more resistant to heat and corrosion. This means that titanium bits last longer than their standard counterparts, providing better value for your investment. For frequent use in demanding environments, titanium drill bits are a reliable choice.

Precision and Efficiency

Precision is crucial in any drilling task. Titanium drill bits offer superior accuracy, ensuring clean and precise holes every time. The reduced friction from the titanium coating also means less effort is required to drill, making your work faster and more efficient. This is especially important in professional settings where time and accuracy are paramount.

Common Applications

- Metalworking: Ideal for drilling into various metals without dulling.

- Woodworking: Perfect for creating clean holes in wood for screws and dowels.

- Plastics: Effective for drilling plastics without cracking or melting.

- Construction: Used in heavy-duty construction projects for precise and reliable drilling.

Table: Comparison of Drill Bit Types

| Feature | Standard Drill Bits | Titanium Drill Bits | Cobalt Drill Bits |

|---|---|---|---|

| Material Compatibility | Wood, Plastic | Metal, Wood, Plastic | Metal, Hard Metals |

| Durability | Moderate | High | Very High |

| Cost | Low | Medium | High |

| Heat Resistance | Low | High | Very High |

| Lifespan | Short | Long | Very Long |

Understanding these aspects can help you determine when and where to use titanium drill bits for maximum effectiveness.

Are Titanium Drill Bits Better?

Confused about which drill bit to choose? Titanium drill bits might be the better option.

Titanium drill bits offer superior durability, longer lifespan, and better performance compared to standard drill bits, making them a better choice for many applications.

But are they always the best option? Let’s explore their advantages and potential drawbacks.

Enhanced Durability

Titanium drill bits are coated with titanium nitride2, which significantly increases their hardness and resistance to wear and tear. This makes them more durable than standard high-speed steel (HSS) drill bits. For tasks that involve drilling into tough materials, titanium bits maintain their sharpness longer, reducing the need for frequent replacements.

Extended Lifespan

The longevity of titanium drill bits is one of their main benefits. The titanium coating not only enhances durability but also provides better heat dissipation. This means that the bits can withstand higher temperatures without losing their edge, allowing for longer use periods and fewer interruptions in your work.

Improved Performance

Titanium drill bits offer improved performance in terms of speed and efficiency. The reduced friction from the titanium coating allows for faster drilling with less effort. This is particularly beneficial in professional settings where time is of the essence. Additionally, the precision offered by titanium bits ensures cleaner and more accurate holes, enhancing the overall quality of your projects.

Cost vs. Value

While titanium drill bits are more expensive upfront compared to standard bits, their extended lifespan and superior performance offer better value in the long run. For frequent use and demanding tasks, the investment in titanium bits pays off through reduced replacement costs and increased productivity.

Potential Drawbacks

Despite their many advantages, titanium drill bits may not be the best choice for every situation. For example, in applications where drilling is infrequent or involves only soft materials, the higher cost may not be justified. Additionally, titanium bits can be more brittle than some other types, making them susceptible to breakage if used improperly.

Conclusion

Titanium drill bits are generally better than standard bits for a wide range of applications due to their durability, lifespan, and performance. However, it’s important to consider the specific needs of your projects to determine if they are the right choice for you.

How Can You Tell if a Drill Bit is For Metal?

Not sure if your drill bit is right for metal? Here’s how to identify it.

Metal drill bits typically have a specific design and material composition, such as cobalt or titanium coatings, to handle the hardness of metals effectively.

Identifying the right drill bit for metal ensures efficient and accurate drilling without damaging your tools or materials.

Material and Coating

Metal drill bits are usually made from high-speed steel (HSS) or cobalt steel. Cobalt drill bits3 have a higher cobalt content, making them harder and more heat-resistant. Titanium-coated drill bits also fall into this category, as the coating provides additional strength and durability for drilling metal.

Tip Design

The tip of a metal drill bit is typically sharper and more pointed compared to bits designed for wood or plastic. This design helps in piercing through tough metal surfaces with ease. Look for a two-flute or three-flute design, which allows for better chip removal and reduces the risk of the bit getting stuck.

Packaging and Labeling

Manufacturers often label their drill bits according to their intended use. Look for packaging that specifies "metal," "HSS," "cobalt," or "titanium." These labels indicate that the drill bit is designed to handle metal drilling tasks effectively.

Testing the Drill Bit

If you’re still unsure, you can perform a simple test. Try drilling into a piece of metal with the bit. If it cuts smoothly without excessive heat or resistance, it’s likely designed for metal. However, ensure you use proper safety measures when performing this test.

Table: Drill Bit Identification

| Feature | Metal Drill Bits | Wood Drill Bits | Plastic Drill Bits |

|---|---|---|---|

| Material | HSS, Cobalt, Titanium-coated | HSS, Carbide | HSS, High-Speed Plastic |

| Tip Design | Sharp, pointed, multi-flute | Blunt, single-flute | Sharp, specialized |

| Appearance | Reddish or golden tint | Shiny or silver | Colorful or standard |

| Packaging Label | "Metal," "HSS," "Cobalt," "Titanium" | "Wood," "Carbide" | "Plastic," "Specialty" |

| Performance Test | Smooth drilling in metal | Easy drilling in wood | Clean cuts in plastic |

Understanding these characteristics can help you select the right drill bit for your metalworking projects.

Safety Considerations

When using metal drill bits, it’s essential to prioritize safety. Metal drilling generates more heat and friction, which can lead to tool damage or personal injury if not handled properly. Always wear appropriate safety gear, such as gloves and eye protection, and ensure your drill is set to the correct speed for the material you’re working with. Proper lubrication can also help reduce heat buildup and extend the life of your drill bit.

Maintenance Tips

To keep your metal drill bits in good condition, regular maintenance is key. After each use, clean the bits thoroughly to remove any metal shavings or debris. Sharpening the tips periodically will ensure they remain effective and precise. Storing your drill bits in a dry, organized space will prevent rust and damage, ensuring they are ready for your next project.

Conclusion

Identifying the right drill bit for metal involves understanding the material, tip design, and specific features that make a bit suitable for metalworking. By paying attention to these factors, you can ensure efficient and accurate drilling, enhancing the quality of your work.

Can I Use a Metal Drill Bit on Wood?

Thinking of using a metal bit for wood? Here’s what you need to know.

While it’s possible to use a metal drill bit on wood, it’s not always the best choice due to differences in design and performance requirements.

Using the right drill bit for the material ensures cleaner holes and extends the life of your tools.

Differences in Design

Metal drill bits are designed to handle hard materials, featuring sharper points and more robust construction. Wood drill bits4, on the other hand, have flatter tips and wider flutes to accommodate wood fibers. Using a metal bit on wood can result in splintered edges and rough holes, as the bit is not optimized for the softer, fibrous nature of wood.

Performance Issues

When using a metal drill bit on wood, you might encounter several performance issues. The sharper tip of a metal bit can cause the wood to tear rather than cut cleanly, leading to splintering. Additionally, metal bits may generate more heat when drilling into wood, which can burn the material and dull the bit more quickly.

Advantages of Using Metal Bits on Wood

Despite the drawbacks, there are scenarios where using a metal drill bit on wood can be beneficial. For instance, if you need to drill through wood and then into metal without changing bits, a metal bit can handle both tasks. This can save time and reduce the need for multiple tools. Additionally, metal bits are generally more durable, making them suitable for heavy-duty wood drilling where precision is less critical.

When to Use Metal Bits on Wood

- Heavy-Duty Projects: For large-scale woodworking projects where speed and durability are more important than precision.

- Multi-Material Drilling: When you need to drill through wood and then into metal, using one bit for both materials can be convenient.

- Larger Holes: Metal bits can handle drilling larger holes in wood without breaking, provided they are used carefully.

Potential Drawbacks

Using metal drill bits on wood can lead to several issues:

- Splintering: The aggressive cutting action can cause wood to splinter and tear.

- Heat Buildup: Increased friction can burn the wood and dull the bit faster.

- Reduced Precision: Metal bits are not designed for the finer, cleaner holes often required in woodworking.

Tips for Using Metal Bits on Wood

If you decide to use a metal drill bit on wood, here are some tips to improve your results:

- Use Lower Speed: Reduce the drill speed to minimize heat buildup and control the drilling process.

- Apply Light Pressure: Avoid pressing too hard, which can cause splintering and bit damage.

- Use Lubrication: Applying a bit of oil can help reduce friction and heat, leading to a cleaner cut.

- Support the Wood: Ensure the wood is properly supported to prevent movement and splintering during drilling.

Table: Drill Bit Comparison for Wood and Metal

| Feature | Metal Drill Bits | Wood Drill Bits |

|---|---|---|

| Tip Design | Sharp, pointed | Flatter, wider flutes |

| Material | HSS, Cobalt, Titanium-coated | HSS, Carbide |

| Performance | High durability, less splintering | Cleaner cuts, less heat |

| Best For | Metal, multi-material projects | Wood, precision drilling |

| Heat Generation | Higher | Lower |

Conclusion

While you can use a metal drill bit on wood, it’s important to understand the potential drawbacks and adjust your technique accordingly. For the best results, choose the drill bit designed specifically for the material you are working with.

Conclusion

Titanium drill bits enhance your drilling tasks with durability and precision.

-

"titanium coating" is critical to understanding the benefits of the material. ↩

-

Titanium nitride is a critical material used to coat drill bits, improving their hardness and wear resistance. ↩

-

Cobalt steel drill bits have specific benefits, like enhanced hardness and heat resistance. ↩

-

"Wood drill bits" are mentioned in the context of differences between metal and wood drill bits. ↩