What is a Carbide Saw Blade?

A carbide saw blade can dramatically improve your cutting efficiency, but what exactly makes it different from other types? If you’re in the market for a saw blade or just curious, you’ve come to the right place.

A carbide saw blade features tungsten carbide tips on its teeth, providing strength and durability, making it ideal for cutting through tough materials like wood, metal, and plastic.

A carbide blade is equipped with teeth that have tungsten carbide tips. These tips make the blade last longer, as tungsten carbide is known for its hardness and wear resistance. But, there’s a lot more to these blades. Let’s dive into the details.

Best Blade for Circular Saw to Cut Wood?

Looking to cut wood with precision and ease? The best circular saw blade for this task is a tungsten carbide-tipped blade. The carbide tips will ensure that the teeth stay sharp longer, even when cutting through dense wood.

A quality carbide blade can provide smoother cuts and longer life compared to standard steel blades, which wear down quickly when cutting through wood. But what are the other factors to consider when choosing a blade for wood?

Dive Deeper

When it comes to selecting a blade for your circular saw, there are several factors to consider. Firstly, the number of teeth on the blade. More teeth typically result in smoother cuts, especially on softer woods. However, blades with fewer teeth are better for quicker cuts through thicker or denser wood.

Another key factor is the blade’s tooth design. A combination blade, for example, has teeth designed for both crosscutting and ripping, making it versatile for various woodcutting tasks. On the other hand, a specialized ripping blade has fewer teeth, designed for fast, rough cuts along the grain.

Size Matters: Most circular saws are compatible with 7 1/4-inch blades, but there are variations. Ensure that you choose the right size blade that fits your specific circular saw model. This will ensure maximum efficiency and safety.

Here’s a quick guide to help you select the best blade for different wood types:

| Wood Type | Recommended Teeth Count | Ideal Blade Type |

|---|---|---|

| Softwood (Pine) | 24-40 teeth | Combination or Ripping Blade |

| Hardwood (Oak) | 60-80 teeth | Fine Tooth Blade |

| Pressure-treated | 24-40 teeth | Ripping Blade |

By considering the type of wood and the required cutting speed, you can choose the best tungsten carbide blade1 to get the job done quickly and effectively.

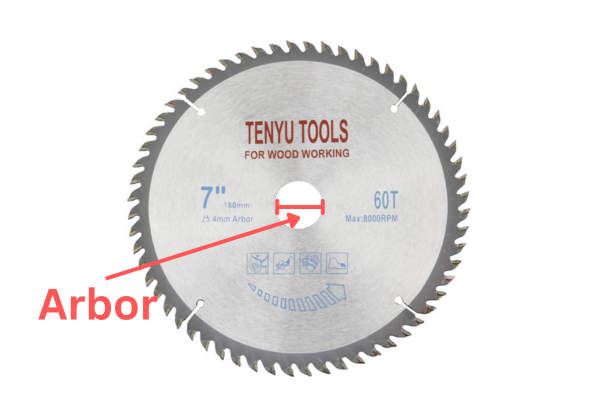

What does Arbor Mean on a Saw Blade?

The term "arbor" on a saw blade might sound technical, but it’s essential to understand. The arbor is the central hole of the blade that fits onto the shaft of the saw.

The arbor is the central part of the saw blade that connects the blade to the saw’s motor. It helps keep the blade in place while the saw operates.

The diameter of the arbor must match the specifications of the saw. This ensures proper fitment and stability while cutting. If the arbor size is too small or too large for your saw, it can cause safety hazards or inefficient cutting performance.

Dive Deeper

The arbor size is typically measured in inches, and it can vary depending on the type of saw. The most common sizes are 5/8 inches and 1 inch, but there are also smaller or larger options depending on the saw’s design.

When choosing a blade, always check the arbor size to ensure compatibility with your saw. If you use the wrong size, you could risk damaging the saw or the blade. For example, a blade with a larger arbor hole will require an adapter to fit onto a saw with a smaller arbor size.

In some cases, the arbor hole2 may be tapered to fit a variety of saw models. This adaptability can make it easier to switch blades between different saws. However, it’s crucial to double-check the blade specifications before installation to ensure everything fits securely.

Additionally, the arbor should be checked for any debris or buildup before use. This helps maintain smooth operation and reduces the risk of accidents caused by a loose or unevenly installed blade.

How Long Does a Circular Saw Blade Last?

You might be wondering how long your circular saw blade will last. The lifespan of a circular saw blade depends on the material it’s cutting, how frequently it’s used, and the quality of the blade itself.

A tungsten carbide-tipped blade can last much longer than regular steel blades, typically 3 to 4 times longer, due to its resistance to wear and heat.

In general, a carbide saw blade can last anywhere from 6 months to several years, depending on the intensity and type of use. Regular maintenance, such as cleaning the blade after use, can further extend its life.

Dive Deeper

Several factors influence the lifespan of a circular saw blade, starting with the material being cut. For example, cutting through hardwood or metal will wear out the blade faster than cutting softwoods or plastic. Even cutting through pressure-treated wood can cause the teeth to dull more quickly due to the added chemicals in the wood.

The frequency of use also plays a significant role. A blade used daily in a professional setting will wear out faster than one used occasionally for DIY projects. However, with the right care, a high-quality tungsten carbide saw blade can provide extended service, even under heavy use.

One way to keep the blade sharp is by having it professionally sharpened when it becomes dull. This can extend the blade’s life, especially for those used in more demanding tasks. Some users also choose to replace the blade when its performance drops, rather than continually maintaining it.

Here’s a general guide to the expected lifespan of a circular saw blade:

| Blade Type | Material Cut | Lifespan Estimate |

|---|---|---|

| Tungsten Carbide-Tipped | Softwood/Hardwood | 1-3 years (with proper care) |

| Tungsten Carbide-Tipped 3 | Metal/Plastic | 6-12 months (with proper care) |

| Steel Blade | Softwood | 6 months-1 year |

To maximize the lifespan, always use the saw blade according to its designed purpose, and avoid using it on inappropriate materials like metal unless it’s a metal-cutting blade.

What is the Best Tool to Use When Cutting Plywood?

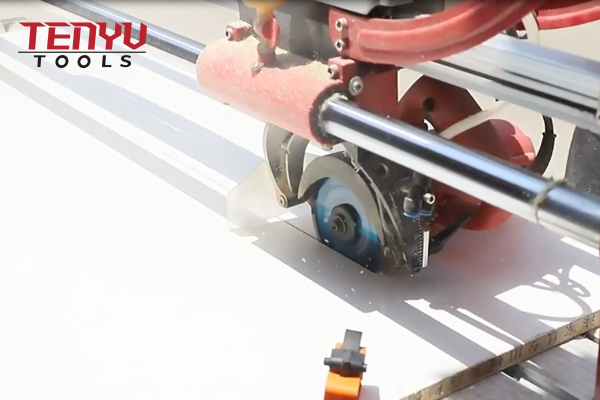

When cutting plywood, choosing the right tool is crucial to ensure clean cuts without splintering. A circular saw is often the best tool for cutting plywood, especially if fitted with a fine-tooth blade.

A circular saw with a fine-tooth tungsten carbide blade can give you precise cuts on plywood with minimal splintering.

The quality of the blade plays a huge role in achieving smooth cuts, and a tungsten carbide-tipped blade will last longer and provide cleaner results than a regular steel blade.

Dive Deeper

Plywood is often a challenge for many saw blades because of its layers. A rough cut can cause the wood to splinter, making the piece less visually appealing and possibly unusable. To avoid this, it’s essential to choose a circular saw with a fine-toothed blade designed for cutting plywood.

A finer-toothed blade reduces the amount of pressure required for cutting, which helps maintain a clean cut while minimizing splintering along the edges. Tungsten carbide-tipped blades, in particular, are ideal because they hold their sharpness for longer, ensuring clean, smooth cuts over an extended period.

Additionally, it’s important to consider the thickness of the plywood4. A thicker sheet will require a saw with higher power and a blade with more teeth to ensure a smooth, accurate cut. For thinner plywood, a blade with fewer teeth can cut faster and more efficiently.

It’s also a good idea to use a sacrificial board (like a scrap piece of plywood) underneath the piece you’re cutting. This helps prevent the bottom layer from splintering during the cut.

Here are some tips for cutting plywood with a circular saw:

| Tip | Description |

|---|---|

| Blade Selection | Use a fine-tooth tungsten carbide blade for smoother cuts |

| Saw Speed | Use moderate speed to avoid splintering |

| Support the Plywood | Place the plywood on a flat surface and support it fully to prevent bowing |

| Protective Gear | Always wear safety glasses and a dust mask when cutting |

With the right technique and blade, you can cut plywood cleanly and efficiently, reducing the need for sanding or trimming after the cut.

Conclusion

Choosing the right tungsten carbide saw blade can make a huge difference in your cutting projects, whether you’re working with wood, plywood, or other materials. By understanding the key features and selecting the right blade, you’ll ensure cleaner cuts, longer tool life, and better results.

-

Tungsten carbide blades are known for their durability and effectiveness in cutting through tough materials. ↩

-

The arbor hole’s design can influence which blades are compatible with a particular saw, especially regarding the need for adapters or tapered holes. ↩

-

Users looking for specialized saw blades will benefit from understanding the durability and benefits of tungsten carbide saw blades. ↩

-

Plywood thickness directly impacts the choice of saw and blade. ↩