What is a HSS Drill Bit?

Drilling issues? Discover the solution with HSS drill bits.

A HSS drill bit is made from high-speed steel, ideal for drilling metal and other tough materials efficiently.

Keep reading to explore everything you need to know about HSS drill bits.

What Is a HSS Drill Bit and When Would You Use It?

Struggling with tough drilling tasks? HSS drill bits can help.

HSS drill bits are crafted from high-speed steel, perfect for drilling through hard materials like metal, wood, and plastics.

Choosing the right tool makes all the difference in your projects. Let’s dive into when and why you should use HSS drill bits.

Understanding HSS Drill Bits

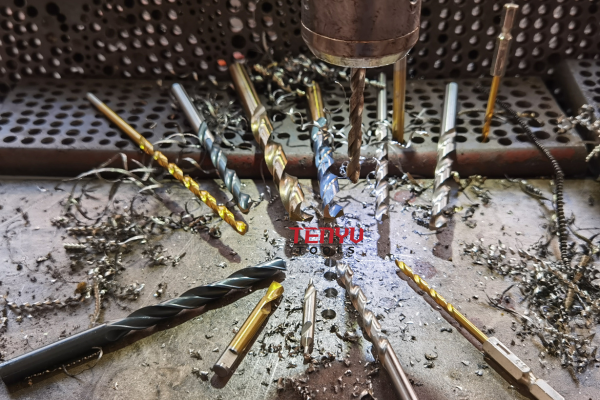

High-Speed Steel (HSS) drill bits are designed to withstand high temperatures without losing their hardness. This makes them ideal for tasks that involve rapid drilling or extended use. Whether you’re working on metal fabrication1, woodworking, or plastic materials, HSS drill bits provide the durability and precision needed for a clean and efficient drill.

Applications of HSS Drill Bits

HSS drill bits are versatile and can be used in various applications:

- Metalworking: Perfect for drilling through steel, aluminum, and other metals.

- Woodworking: While twist drill bits can be used for wood, brad point bits are more suitable for creating clean and precise holes.

- Plastics: Efficient in drilling through plastic materials without cracking.

- DIY Projects: Great for home improvement tasks, from assembling furniture to installing fixtures.

Advantages of Using HSS Drill Bits

- Durability: Resistant to wear and can maintain sharpness over time.

- Heat Resistance: Can operate at higher speeds without degrading.

- Versatility: Suitable for multiple materials and applications.

- Cost-Effective: Long-lasting, reducing the need for frequent replacements.

Choosing the Right HSS Drill Bit

When selecting an HSS drill bit, consider the material you’ll be drilling, the size of the hole required, and the specific application. Investing in high-quality HSS drill bits ensures better performance and longer lifespan, making your projects smoother and more efficient.

How to Identify HSS Drill Bits?

Confused by drill bit types? Identifying HSS bits is simple.

HSS drill bits show high-speed steel composition.

Let’s explore how you can easily recognize HSS drill bits among other types.

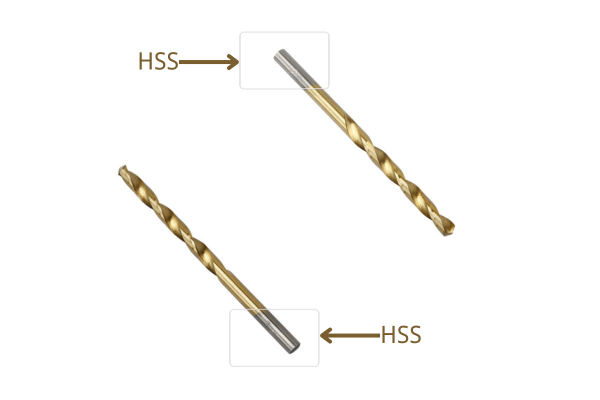

Markings and Labels

Manufacturers often stamp HSS drill bits with specific markings that indicate their material and quality. Look for labels like "HSS" or "High-Speed Steel" engraved on the shank or body of the bit. These markings help differentiate them from cobalt2, carbide, or titanium-coated drill bits.

Shank Design

The shank of an HSS drill bit is typically uniform and may feature a straight or reduced shank design. This design ensures a secure fit in the drill chuck, providing stability during use. Some HSS bits also have hex shanks for quick and easy bit changes.

Testing for HSS Drill Bits

If you’re unsure about a drill bit’s material, a simple test can help. HSS drill bits are harder and more resilient than standard carbon steel bits. You can perform a scratch test using a file or another hard tool. HSS bits will resist scratching better, confirming their high-speed steel composition.

The Beginner’s Guide to High-Speed Steel (HSS) Drill Bits

New to drilling? HSS drill bits are your best start.

High-Speed Steel (HSS) drill bits are essential tools for beginners, offering reliability and ease of use across various materials.

Let’s explore the basics of HSS drill bits to help you get started with confidence.

What is High-Speed Steel?

High-Speed Steel is a subset of tool steels3 known for their ability to retain hardness at elevated temperatures. This property makes HSS drill bits ideal for high-speed drilling operations without losing their cutting edge. HSS is alloyed with elements like tungsten, molybdenum, and chromium, enhancing its strength and durability.

Benefits for Beginners

For those new to drilling, HSS drill bits offer several advantages:

- Ease of Use: They are forgiving and work well with standard drill machines.

- Versatility: Suitable for a wide range of materials, reducing the need for multiple bits.

- Cost-Effective: Provide excellent performance without a hefty price tag, making them ideal for budget-conscious users.

- Availability: Widely available in various sizes and shapes, making it easy to find the right bit for your project.

Types of HSS Drill Bits

There are several types of HSS drill bits, each designed for specific tasks:

- Twist Drill Bits: The most common type, suitable for general-purpose drilling in various materials.

- Brad Point Bits: Specifically designed for woodworking, providing clean and precise holes with minimal splintering.

- Step Bits: Ideal for drilling multiple hole sizes without changing bits.

- Countersink Bits: Used to create a conical hole for screw heads to sit flush.

Maintenance Tips

To ensure the longevity of your HSS drill bits:

- Keep Them Sharp: Regularly sharpen the tips to maintain efficiency.

- Proper Storage: Store in a dry place to prevent rusting.

- Use Correct Speed: Match the drill speed to the material to avoid overheating.

- Clean After Use: Remove any debris or residue after drilling to prevent buildup.

Safety Considerations

Always wear appropriate safety gear, such as goggles and gloves, when using HSS drill bits. Ensure the drill bit is securely fastened in the chuck and check for any damage before use. Proper handling and maintenance not only extend the life of your bits but also ensure safe operation.

How do You Choose the Right Drill Bit for the Job?

Overwhelmed by choices? Picking the right drill bit is easier than you think.

Choosing the right drill bit depends on the material, hole size, and specific application to ensure efficiency and accuracy.

Let’s break down the factors to consider when selecting the perfect drill bit for your project.

Material Considerations

Different materials require different types of drill bits. For instance:

- Wood: While twist drill bits can be used for wood, brad point bits are more suitable for creating clean and precise holes.

- Metal: High-Speed Steel (HSS) 4or cobalt bits are ideal.

- Masonry: Carbide-tipped bits are necessary for drilling into concrete or brick.

- Plastic: Standard HSS bits work well without causing cracks.

Hole Size and Depth

Determine the size and depth of the hole you need. Using a drill bit that matches the required diameter ensures precision. For deeper holes, consider using a bit with a longer shank or a step bit to reach the desired depth without frequent bit changes.

Application Specifics

Consider the purpose of the hole:

- Precision: For tasks requiring high accuracy, such as cabinetry, use sharp and finely ground bits like brad point bits.

- Speed: For rapid drilling, choose bits that can handle high RPMs without overheating.

- Finish: If a smooth finish is essential, opt for bits designed to reduce splintering and rough edges.

Compatibility with Drill

Ensure the drill bit is compatible with your drill. Check the shank size and type to match your drill’s chuck. Hex shanks are useful for quick changes, while round shanks offer versatility across different drill types.

Budget and Quality

Balance your budget with the quality needed for your projects. While high-quality bits might cost more upfront, their durability and performance can save money in the long run by reducing the need for replacements and improving efficiency.

Recommended Drill Bits

TENYU TOOLS offer reliable performance. Look for well-reviewed products that meet your specific needs, ensuring you get the best value for your investment.

What is the History of Drill Bits?

Curious about drill bits? Their history is fascinating and rich.

Drill bits have evolved from simple hand tools to advanced, specialized bits, revolutionizing construction and manufacturing over centuries.

Let’s journey through the history of drill bits and see how they have transformed over time.

Early Beginnings

The concept of drilling dates back to ancient civilizations. Early drill bits5 were made from flint, bone, or wood, used primarily for creating holes in materials like wood and leather. These primitive tools were slow and required significant manual effort.

The Invention of Metal Drill Bits

With the advancement of metallurgy, metal drill bits began to emerge. By the Middle Ages, blacksmiths crafted drill bits from iron, improving durability and efficiency. These metal bits allowed for faster and more precise drilling, essential for woodworking and metalworking.

The Industrial Revolution

The Industrial Revolution marked a significant leap in drill bit technology. The introduction of high-speed steel (HSS) in the late 19th century revolutionized drilling. HSS drill bits could withstand higher temperatures and maintain their hardness, making them ideal for mass production and industrial applications.

Advancements in Design

Throughout the 20th century, drill bits saw numerous design improvements:

- Twist Drill Bits: Invented in the late 19th century, these became the standard for general-purpose drilling.

- Cobalt Drill Bits: Developed to handle harder materials like stainless steel.

- Carbide-Tipped Bits: Created for drilling into masonry and other tough surfaces.

- Specialized Bits: Such as step bits and brad point bits, designed for specific tasks and materials.

Modern Innovations

Today, drill bits incorporate advanced materials and coatings to enhance performance. Titanium coatings, for example, extend the life of HSS bits by reducing friction and heat buildup. Computer-aided design (CAD) and manufacturing (CAM) have also allowed for more precise and efficient drill bit geometries, catering to a wide range of industrial and DIY applications.

The Future of Drill Bits

The future holds continued innovation in drill bit technology. Developments in materials science and manufacturing techniques promise even more durable, efficient, and specialized drill bits. Automation and smart technology may also integrate with drill bits, offering features like real-time performance monitoring and adaptive drilling capabilities.

What are Some Good Drill Bits?

Looking for quality? Here are some top drill bits you can trust.

High-quality drill bits ensure precision, durability, and efficiency, making your projects smoother and more reliable.

Let’s explore some of the best drill bits available to meet your various needs.

High-Speed Steel (HSS) Drill Bits

HSS drill bits are a staple for many projects due to their versatility and durability. They perform well on materials like wood, metal6, and plastic, making them ideal for both professional and DIY use. Brands like TENYU TOOLS offers reliable HSS bits known for their sharpness and longevity.

Cobalt Drill Bits

For tougher materials such as stainless steel and other hard metals, cobalt drill bits are an excellent choice. They are more expensive but provide superior heat resistance and durability. Milwaukee and Irwin are renowned for their high-quality cobalt bits that deliver consistent performance. TENYU TOOLS also can provide it.

Carbide-Tipped Drill Bits

When drilling into masonry, concrete, or other extremely hard materials, carbide-tipped drill bits are essential. These bits maintain their edge and withstand the abrasive nature of these surfaces. Brands like Makita and Hilti offer top-notch carbide-tipped bits trusted by professionals in construction and masonry.

Titanium-Coated Drill Bits

Titanium-coated drill bits offer enhanced performance by reducing friction and extending the bit’s life. They are ideal for drilling into metal and other tough materials while maintaining sharpness. Craftsman and Stanley provide excellent titanium-coated options that balance performance and affordability.

Step Drill Bits

Step drill bits are perfect for tasks requiring multiple hole sizes without changing bits. They are commonly used in metalworking and electrical installations. Brands like Irwin and Milwaukee offer durable step bits that provide precision and efficiency for varied applications.

Brad Point Drill Bits

For woodworking projects, brad point drill bits are the best choice. Although twist drill bits can be used for wood, brad point bits create cleaner and more precise holes with minimal splintering, making them ideal for cabinetry and furniture making. Popular options include those from Frearson and Bosch, known for their sharp points and reliable performance.

Masonry Drill Bits

Specialized for drilling into brick, stone, and concrete, masonry drill bits are built to handle tough materials. They often feature a carbide tip for maximum durability. Brands like DeWalt and Bosch offer high-quality masonry bits that ensure efficient and accurate drilling in construction projects.

Choosing the Right Brand

Selecting the right brand can make a significant difference in performance and longevity. Reputable brands invest in quality materials and advanced manufacturing processes, ensuring their drill bits meet high standards. Reading reviews and seeking recommendations can help you choose the best drill bits for your specific needs.

How to Choose the Right Size Drill Bit?

Unsure about sizes? Picking the right drill bit size is crucial.

Choosing the right size drill bit ensures accurate holes and prevents material damage, enhancing your project’s success.

Let’s break down how to select the appropriate drill bit size for your tasks.

Determining Hole Diameter

The first step is to identify the required hole diameter. This depends on the application:

- Screws and Bolts: Match the drill bit size7 to the screw or bolt diameter for a snug fit.

- Wiring and Cabling: Ensure the hole is large enough to accommodate cables without strain.

- Plumbing: Choose sizes that fit pipes and fittings precisely.

Measuring Techniques

Accurate measurement is key to selecting the correct drill bit size:

- Use a Caliper: Measure the exact diameter of the screw, bolt, or object that needs to fit through the hole.

- Gauge Block: Utilize a gauge block to compare different drill bit sizes until you find the perfect match.

- Drill Bit Set: Refer to a drill bit size chart to match the required diameter with standard bit sizes.

Considering Material Thickness

The thickness of the material affects the drill bit size selection. Thicker materials may require longer drill bits or bits with more robust construction to penetrate effectively without breaking.

Application-Specific Requirements

Different applications have unique size requirements:

- Precision Work: Requires exact sizes to ensure proper fit and alignment.

- General Drilling: May allow for slight variations in hole size without affecting functionality.

- Heavy-Duty Tasks: Necessitate larger bits for substantial holes and robust performance.

Using Drill Guides and Templates

For projects requiring multiple holes of the same size, using drill guides or templates ensures consistency and accuracy. These tools help maintain the correct drill bit size and alignment throughout the project.

Common Drill Bit Sizes and Uses

Here’s a quick reference table for common drill bit sizes and their typical applications:

| Drill Bit Size | Common Use |

|---|---|

| #1 to #3 | Small screws and pilot holes |

| #4 to #8 | Medium screws and bolt holes |

| #9 to #12 | Larger bolts and plumbing applications |

| 1/8" to 1/2" | Wiring, cables, and plumbing |

| 3/4" and up | Large pipes and heavy-duty tasks |

Adjusting for Material Type

Harder materials may require slightly larger drill bits to account for increased resistance and prevent bit breakage. Conversely, softer materials might allow for smaller bits without compromising hole integrity.

Testing and Verification

Before committing to a project, perform a test drill on a scrap piece of material. This practice helps verify the drill bit size and ensures it meets the project’s requirements without damaging the workpiece.

Conclusion

Choosing TENYU TOOLS HSS drill bits enhances your drilling efficiency and project quality.

-

directly relates to a common industry where HSS drill bits are used. ↩

-

refers to a specific type of drill bit made from cobalt alloys. ↩

-

a broad category of materials, and linking to an authoritative resource. ↩

-

explain the advantages of using HSS or cobalt bits for metal drilling. ↩

-

are an essential part of drilling technology, and providing more detailed information about their development. ↩

-

directly targets the performance of HSS drill bits on metal, and it’s a crucial aspect of their functionality. ↩

-

provide additional insights into selecting the right drill bit size based on the material being drilled. ↩