Who Makes the Best Circular Saw Blades?

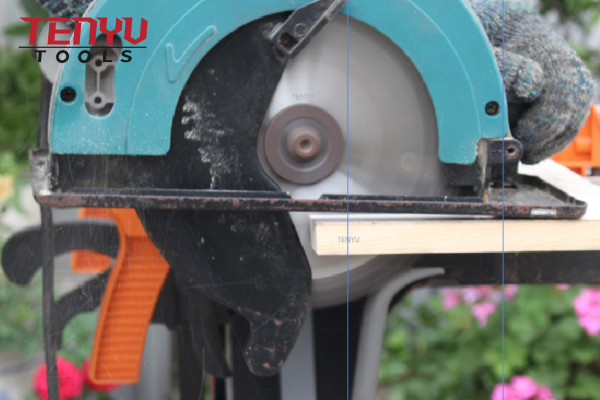

Cutting through wood, metal, or concrete is only as good as the blade you’re using. But with so many options out there, how do you choose the best circular saw blade for your needs? Let’s dig into the top options on the market and help you find the right one.

When you’re after the best circular saw blades, you need to consider several factors: type of material, purpose, and cutting precision. The right blade can make all the difference in achieving smooth, clean cuts without unnecessary effort. In this article, we’ll break down the best choices for finish cuts, plywood, wood, and more.

TENYU TOOLS makes the best circular saw blades

At TENYU TOOLS1, we take pride in producing top-quality circular saw blades designed for a variety of tasks. Whether you’re cutting through plywood, wood, or making finish cuts, our blades are built to provide precision and durability. With over 15 production lines, we ensure consistent performance and reliable delivery. Our circular saw blades are designed to give you the best cut every time.

Best Circular Saw Blade for Finish Cuts?

If you’re working on a project that requires the cleanest, smoothest edges, choosing the right circular saw blade for finish cuts is crucial. Nobody wants rough edges that need to be cleaned up after cutting. Here’s why selecting a quality blade is essential.

The best blade for finish cuts will have more teeth, ensuring a smoother finish without splintering. Blades with a higher tooth count (usually 80 to 100 teeth) are perfect for finish cuts, especially on fine wood or delicate materials. These blades are designed to minimize tear-out and create edges that are smooth right after the cut.

Why More Teeth Matter for Finish Cuts

When you need a perfect finish, the number of teeth on your blade matters. Fewer teeth might cut faster, but they can leave rough edges behind. More teeth help to produce cleaner, finer cuts.

Here’s a quick look at the difference:

| Teeth Count | Effect on Cut Quality |

|---|---|

| 24 Teeth | Fast cuts, rough finish |

| 40 Teeth | Good balance of speed and finish |

| 80-100 Teeth | Smooth, clean cut, ideal for fine finishes |

These blades also tend to be made from higher-quality steel2, ensuring they remain sharp longer and don’t lose performance over time. It’s important to choose a brand known for durability and consistency when making these types of cuts.

Best Circular Saw Blade for Plywood?

When working with plywood, you want a blade that can slice through the layers cleanly without chipping the surface. Finding the best circular saw blade for plywood can save you time and effort, ensuring a professional-looking result.

For plywood, the best circular saw blades are often fine-toothed, with a tooth count that’s high enough to minimize chipping but not so high that it slows down cutting speed. Blades with around 60 to 80 teeth are usually the perfect middle ground. The material itself can be fragile, so it’s critical to use a blade designed to minimize damage to the edges.

Factors to Consider for Cutting Plywood

Plywood can be tricky to cut. It’s not as solid as hardwood, but it requires precision to avoid splintering the surface. The main factors you need to consider are tooth count and blade material. Here’s how they impact your results:

- Tooth Count3 – As mentioned, the higher the tooth count, the smoother the cut. For plywood, 60-80 teeth are ideal for a fine, smooth finish.

- Blade Material – Blades made from tungsten carbide are particularly good at handling plywood as they stay sharp longer, even when cutting through layered material.

- Cutting Speed – Choose a blade that balances speed with smoothness to avoid over-cutting and damaging your plywood.

You can also consider blades with a triple-chip grind, as these are designed to minimize chipping and produce clean, precise cuts.

Best Circular Saw Blade for Wood?

When it comes to cutting wood, whether for furniture, framing, or DIY projects, you want a blade that can handle the material’s density without getting bogged down. So, what’s the best circular saw blade for wood?

For general wood cutting, you’ll find that blades with 24 to 40 teeth perform best. These blades strike the perfect balance between speed and quality. While they won’t offer the same smoothness as finish-cut blades, they get the job done quickly and efficiently.

Why 24 to 40 Teeth Are Best for Wood

The lower tooth count (compared to blades for finer cuts) allows for faster, rougher cuts through wood without bogging down. These blades are built for high-speed cuts and can handle most types of wood, including hardwoods4 and softwoods. The teeth are usually set with a rake angle that helps them slice through materials without creating too much drag.

Comparing Wood Cutting Blades

| Teeth Count | Ideal For | Cut Quality | Speed |

|---|---|---|---|

| 24 Teeth | Framing, rough cuts | Rougher | Faster |

| 40 Teeth | General wood cuts | Balanced | Moderate |

| 60+ Teeth | Finish cuts | Smoother | Slower |

These blades will also come in different designs, such as carbide-tipped, which helps maintain sharpness for longer.

Circular Saw Blade Teeth Guide

One of the most important aspects of selecting the right circular saw blade is understanding the teeth. The design and number of teeth on the blade can affect the cut quality, speed, and efficiency.

Types of Teeth and What They Do

Circular saw blades come with several different types of teeth. Here’s a quick breakdown of the most common:

- Flat Top Grind (FTG)5: The teeth are flat and straight, which makes them great for cutting through wood quickly. These blades are often used for framing and rough cuts.

- Alternate Top Bevel (ATB): These blades alternate between teeth that are beveled to the left and right, providing smooth cuts and reducing the chances of splintering. Ideal for fine woodworking and plywood.

- Triple Chip Grind (TCG): These blades feature teeth that alternate between flat and bevel-edged, making them perfect for cutting through tough materials like MDF and plywood with a clean finish.

Tooth Geometry Matters

The geometry of the teeth also plays a significant role. A blade with positive rake angles will cut more aggressively and faster, while a negative rake can provide a slower, more controlled cut.

Conclusion

Choosing the right circular saw blade depends on your cutting needs. Whether it’s for fine finish cuts, plywood, or general wood, the key is understanding the material and the purpose of your cuts. TENYU TOOLS offers the best circular saw blades designed to make your cutting tasks smoother and more efficient.

-

"TENYU TOOLS" helps provide authoritative information on the brand and its reputation in the industry. ↩

-

Steel is a crucial material in making durable blades. ↩

-

"tooth count" directly affects the smoothness and precision of cuts in plywood. ↩

-

provides a more detailed definition of hardwoods, which is a common term used in woodworking. ↩

-

FTG blades are commonly used for rough cuts and framing. ↩