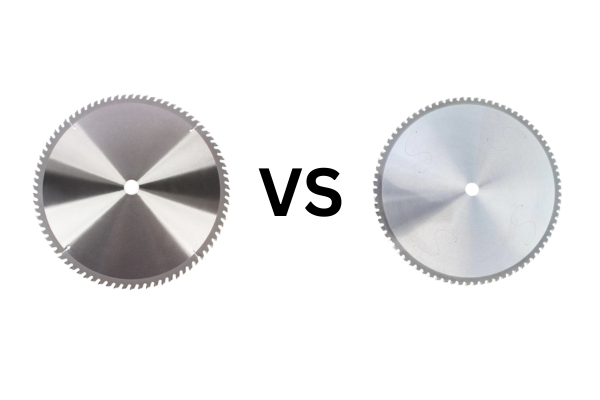

Wood Blade vs Metal Blade: Which One Should You Choose?

If you’ve ever found yourself standing in the tool aisle, wondering whether to pick a wood blade or a metal blade for your project, you’re not alone. Choosing the right blade for the job can be tricky, but it’s crucial for achieving clean, precise cuts. In this article, I’ll help clear up the confusion and guide you through the differences, so you can make the right choice for your next cutting task.

Knowing the difference between wood blades and metal blades is essential for choosing the right tool for your project. In this article, I will compare wood and metal blades, explain how to use them, and answer some common questions to help you make an informed decision.

Are you ready to dive in? Let’s take a look at how these two blades differ and which one works best for your needs.

What Kind of Saw Cuts Through Metal?

Cutting through metal might seem daunting, but with the right tools, it’s completely achievable. A saw designed to cut through metal usually comes with a specific blade made from durable, high-strength materials.

A metal-cutting saw typically uses blades made from hardened steel or carbide-tipped teeth. These blades are designed to withstand the high friction and heat that come with cutting tough materials like steel, aluminum, or iron. Regular wood blades are not designed for these conditions and may wear out quickly or even break.

Types of Saws for Metal Cutting

There are several types of saws that can handle metal, each designed to offer different benefits based on the material you’re working with:

- Circular Saws: Circular saws equipped with metal-cutting blades are a popular choice for cutting metal sheets and pipes.

- Miter Saws1: A miter saw with a carbide-tipped blade can make precise cuts on metal, especially for angled cuts.

- Band Saws: These are useful for cutting both small and large metal pieces, providing smooth cuts.

- Reciprocating Saws: Ideal for demolition or cutting through thick metal pipes or steel frames.

Tip: Always make sure that the saw and blade you are using are rated for the type of metal you are cutting. This helps avoid damage to your tools and ensures the best results.

Common Metal-Cutting Blades

A few of the most common types of blades used for metal cutting include:

| Blade Type | Material | Ideal Use Case |

|---|---|---|

| Carbide-Tipped | Tungsten Carbide | Heavy-duty metal cutting |

| Bi-Metal | Steel & High-Speed Steel | Versatile, cuts through various metals |

| Cobalt | Cobalt Alloy | Tougher metals like stainless steel |

| Abrasive Wheels | Ceramic or Aluminum Oxide | Cutting thin metals or pipes |

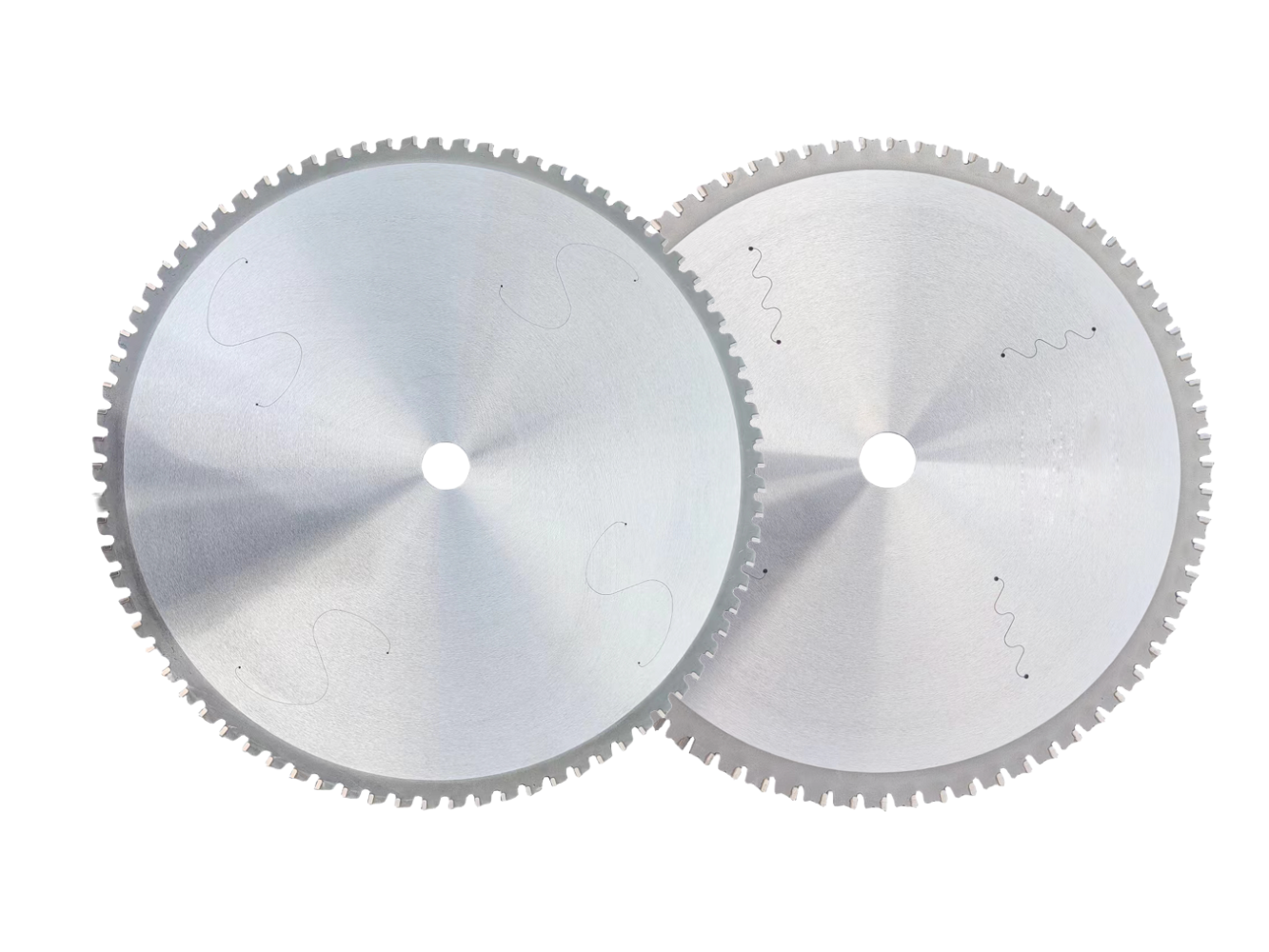

What is TCT Saw Blade? How is it Useful for Metal Cutting?

When you’re cutting metal, using the right type of saw blade can make all the difference in terms of performance, durability, and safety. One blade type that stands out is the TCT (Tungsten Carbide Tipped) saw blade.

TCT saw blades are designed with tungsten carbide tips to help cut through harder materials like metal. These blades are durable and maintain their sharpness much longer than standard steel blades, making them ideal for metal cutting.

Advantages of TCT Blades for Metal Cutting

- Durability: Tungsten carbide is a hard material that resists wear and tear, making TCT blades suitable for cutting tough metals like stainless steel2 or cast iron.

- Precision: The teeth of TCT blades maintain their sharpness longer, which leads to smoother, more precise cuts.

- Longer Blade Life: These blades tend to last much longer compared to standard metal-cutting blades.

- High Cutting Efficiency: TCT blades can handle large volumes of cutting, making them ideal for industrial settings where productivity is key.

Common Uses for TCT Blades

TCT saw blades are commonly used for:

- Cutting thick steel: Ideal for industrial applications, TCT blades can handle thicker pieces of steel with ease.

- Wood and metal cutting: Some TCT blades are designed to cut both wood and metal, making them versatile for various projects.

- Construction: Contractors often use TCT blades for cutting pipes, beams, or rebar in construction projects.

TCT blades are incredibly versatile and valuable for metal cutting tasks, providing a high level of efficiency and a long lifespan.

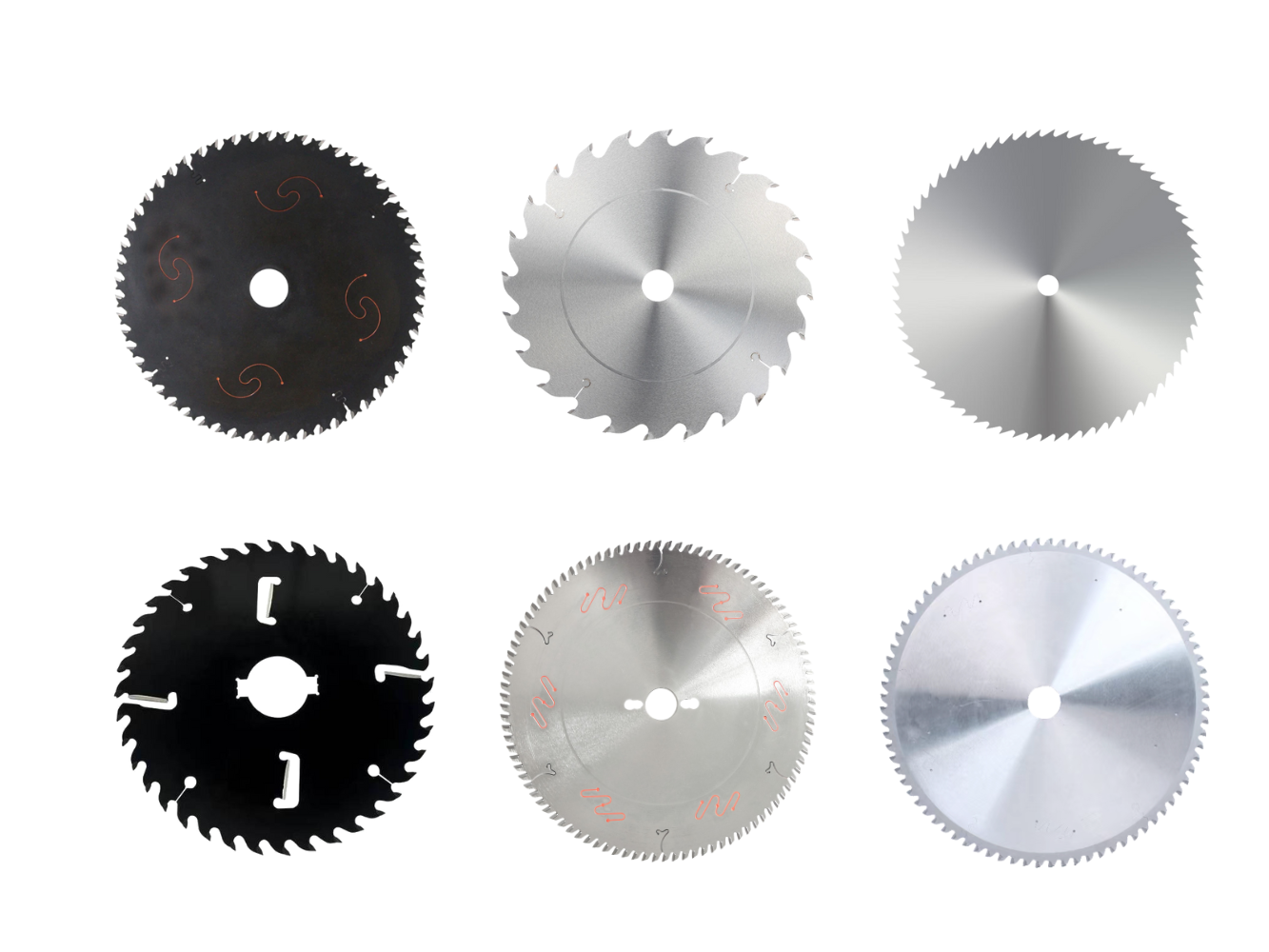

Best Circular Saw Blade for Cutting Wood?

Choosing the best circular saw blade for wood can be just as important as choosing a blade for metal. After all, different types of wood and cuts demand different types of blades.

The best circular saw blade for cutting wood typically has teeth designed for smooth, efficient cutting without causing splintering or rough edges. It is important to choose a blade that matches the type of wood you are working with.

Types of Circular Saw Blades for Wood

There are several types of circular saw blades designed for different woodcutting needs:

- Crosscut Blades: These blades have more teeth and are ideal for cutting across the grain of wood. They produce a smooth cut and are commonly used for trim work and finish cuts.

- Rip Blades3: These blades are designed with fewer teeth and are used for cutting along the grain of the wood. Rip blades cut faster but can leave rough edges.

- Combination Blades: These blades offer a mix of crosscut and rip features, making them ideal for general woodworking tasks.

Features to Look for in a Wood Blade

- Tooth Count: A higher tooth count results in a smoother cut, while fewer teeth allow for faster cuts.

- Blade Material: Carbide-tipped blades tend to last longer and stay sharper, especially for hardwoods.

- Size: Circular saw blades come in various diameters. Ensure the blade fits your saw and is appropriate for the thickness of the wood.

Recommended Wood Blades for Different Types of Wood

| Wood Type | Blade Type | Tooth Count | Best Use Case |

|---|---|---|---|

| Softwood | Crosscut Blade | 40-80 teeth | General cutting |

| Hardwood | Combination Blade | 60-100 teeth | Precision cuts |

| Plywood | Fine Tooth Blade | 100+ teeth | Smooth cuts |

| MDF or Particle Board | Fine Tooth Blade | 80-100 teeth | Smooth, clean edges |

Can I Use a Metal-Cutting Blade on Wood?

This is a common question, especially for DIY enthusiasts who want to make do with the tools they already have. While it might be tempting to use a metal-cutting blade for wood, it’s important to understand the potential downsides.

Technically, you can use a metal-cutting blade on wood, but it’s not recommended for several reasons. Metal-cutting blades are designed to handle tougher materials, and using them on wood can lead to rough cuts, excessive heat buildup, and potential damage to both the blade and the wood.

Why You Should Avoid Using a Metal-Cutting Blade on Wood

- Teeth Design4: Metal blades have fewer, larger teeth, which are designed to cut through tough metal. This makes them inefficient at cutting wood and can lead to rough, jagged edges.

- Heat Buildup: Metal blades generate more heat when cutting wood. This can cause the wood to burn, producing unpleasant odors and potentially damaging the wood.

- Blade Damage: Metal blades are harder and more brittle than wood blades, and they may crack or dull faster when used on wood.

- Safety Issues: Since metal blades are designed to withstand tougher materials, using them on wood could cause them to break or shatter, potentially causing injury.

When to Use a Metal-Cutting Blade on Wood

If you’re in a pinch and only have a metal-cutting blade available, it’s possible to use it for some rough cuts, but only on softer woods or for non-finish cuts. Just be sure to keep the saw at a slower speed and allow for extra cooling time to avoid overheating.

Conclusion

Choosing between wood and metal blades comes down to understanding their specific uses and limitations. Always match the blade to the material you’re cutting for the best results. Whether you’re working with wood or metal, having the right blade will make a huge difference in the quality of your work.

-

This link provides valuable insights into the specific advantages of using carbide-tipped blades with miter saws. ↩

-

providing more detailed information on the material’s hardness and challenges in cutting it effectively. ↩

-

offering users an in-depth understanding of their unique purposes and applications in woodcutting. ↩

-

The teeth design of metal blades is a critical factor in their performance on different materials. ↩