Drilling glass can be tricky. You want precision without cracks or breaks.

Drilling a hole in glass is achievable with the right techniques and tools, ensuring a clean and safe outcome.

Stay with me as we explore the best methods to achieve flawless results.

Avoiding Cracks and Shatters: How to Drill Holes in Glass?

Drilling glass without causing damage seems daunting, doesn’t it?

Yes, it is possible to drill holes in glass by following proper techniques and using the right tools.

Let’s dive into the steps to prevent cracks and shatters.

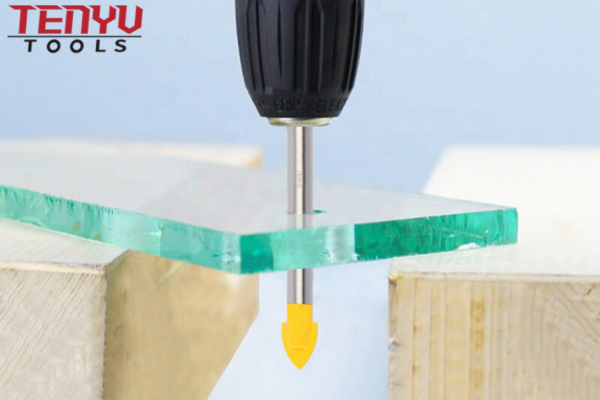

When drilling glass, the key is to minimize stress and heat. Start by marking the spot where you want the hole. Use a non-permanent marker to avoid slipping. Secure the glass firmly on a stable surface to prevent movement. Applying consistent, gentle pressure is crucial. Avoid forcing the drill; let the tool do the work. Lubricate the drilling area with water to reduce friction and heat buildup. This helps prevent cracks caused by overheating. Choose a slow drill speed to maintain control and precision. Patience is your ally here; rushing can lead to mistakes and breakage. Additionally, using tape over the drilling spot can provide extra stability and prevent the drill from slipping. Remember, safety first: wear protective gear like gloves and goggles to safeguard against any accidental shards. By following these steps, you can achieve a clean hole in the glass without damaging it.

Steps to Prevent Cracks and Shatters

- Mark the Spot: Use a non-permanent marker1 for precision.

- Secure the Glass: Ensure the glass is stable and won’t move.

- Use Gentle Pressure: Let the drill do the work without forcing it.

- Lubricate with Water: Keeps the drilling area cool and reduces friction.

- Slow Drill Speed: Maintains control and precision.

- Apply Tape: Provides extra stability and prevents slipping.

- Wear Protective Gear: Safety is paramount.

By meticulously following these steps, you reduce the risk of cracking or shattering the glass during the drilling process.

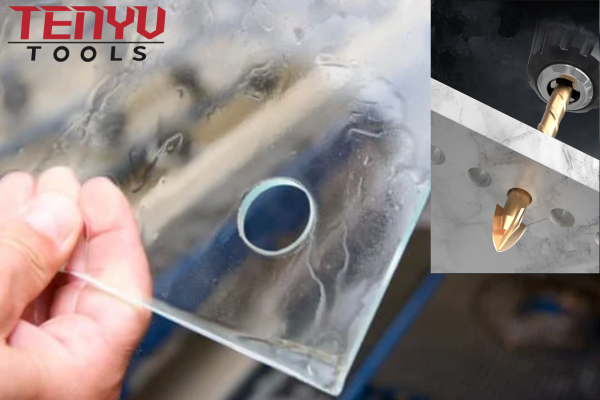

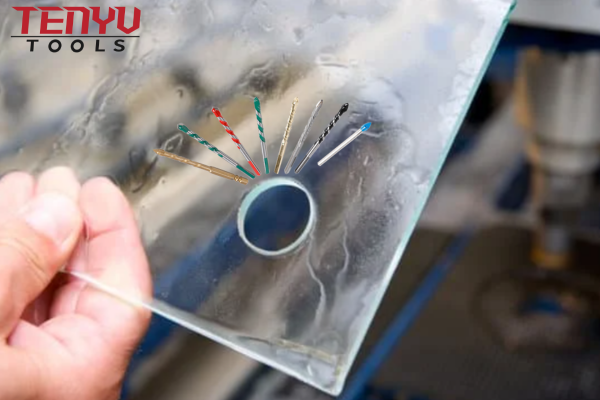

Best Bits to Use for Drilling Glass?

What are the ideal drill bits for glass?

Carbide tip drill bits are the best choice for drilling glass due to their durability and precision.

Choosing the right bit is essential for a successful drilling experience.

When it comes to drilling glass, the choice of drill bit can make or break your project. Carbide tip drill bits stand out as the top choice. These bits are engineered to handle the hardness and brittleness of glass without causing damage. The carbide tip provides the necessary sharpness and durability to penetrate the glass smoothly. Unlike standard bits, carbide tip bits reduce the risk of slipping and wandering, ensuring that the hole is drilled accurately where you want it. Additionally, these bits generate less heat, which is crucial for preventing cracks caused by thermal stress. It’s also advisable to use a diamond-coated drill bit for added precision and longevity. These specialized bits maintain their sharpness longer and provide a cleaner cut. Investing in high-quality drill bits not only enhances the quality of your work but also extends the lifespan of the tools. Proper maintenance, such as cleaning the bits after use and storing them in a dry place, will keep them in optimal condition for future projects. By selecting the right drill bit, you set the foundation for a successful and safe drilling process.

Advantages of Carbide Tip Drill Bits

- Durability: Last longer without dulling.

- Precision: Ensures accurate hole placement.

- Heat Reduction2: Minimizes the risk of cracking due to heat.

- Stability: Prevents slipping and wandering during drilling.

- Efficiency: Drills through glass smoothly and effectively.

Choosing carbide tip drill bits over standard options significantly enhances your ability to drill glass cleanly and safely.

How Can I Properly Drill a Glass Bottle?

Drilling a glass bottle correctly requires careful handling, right?

Absolutely. Using the right technique and tools ensures a clean hole without breaking the bottle.

Let me guide you through the process step by step.

Drilling a glass bottle might seem intimidating, but with the proper approach, it’s entirely manageable. Start by selecting a suitable drill bit, preferably a carbide tip or diamond-coated bit, to ensure smooth drilling. Clean the bottle thoroughly and mark the exact spot where you want the hole. Applying masking tape over the mark can help prevent the drill bit from slipping. Secure the bottle firmly in a vise or use clamps to hold it steady, ensuring it doesn’t move during the drilling process. Begin drilling at a low speed, applying gentle pressure to avoid cracking the glass. It’s crucial to keep the drill bit perpendicular to the bottle’s surface to maintain an even hole. Continuously lubricate the drilling area with water to dissipate heat and reduce friction. This not only prevents thermal stress but also keeps the drill bit cool. Take your time, allowing the bit to gradually penetrate the glass without forcing it. Once the hole is drilled, smooth any rough edges with fine-grit sandpaper to prevent injury and enhance the bottle’s appearance. Finally, clean the bottle again to remove any debris or residue from the drilling process. By following these steps, you can successfully drill a hole in a glass bottle without causing damage.

Tips for Drilling a Glass Bottle

- Choose the Right Bit: Use carbide tip or diamond-coated bits3.

- Mark Precisely: Use masking tape to prevent slipping.

- Secure the Bottle: Ensure it doesn’t move during drilling.

- Drill Slowly: Apply gentle pressure at a low speed.

- Lubricate Continuously: Use water to cool the drill bit.

- Maintain Perpendicular Angle: Keeps the hole even.

- Smooth Edges: Use sandpaper for a clean finish.

Proper preparation and careful execution are key to drilling glass bottles effectively and safely.

Is It Possible to Drill Through Glass?

Is drilling all the way through glass feasible?

Yes, it is entirely possible to drill through glass with the right methods and tools.

Let’s explore how you can achieve this successfully.

Drilling through glass is a task that requires precision and the appropriate tools. The process is similar to drilling on any other hard surface but demands extra caution to prevent damage. Begin by selecting a high-quality drill bit, such as a carbide tip or diamond-coated bit, which can handle the hardness of glass. Mark the drilling spot clearly and apply masking tape to provide stability and prevent the drill bit from slipping. Secure the glass firmly using a vise or clamps to keep it steady during drilling. Start with a low drill speed to maintain control and reduce heat generation, which can cause the glass to crack. It’s essential to apply steady, even pressure without forcing the drill, allowing the bit to do the work naturally. Keep the drilling area lubricated with water to cool the bit and the glass, minimizing the risk of thermal stress and cracks. As you drill, periodically check the progress and adjust as needed to ensure a straight and clean hole. Once you have drilled through the glass, remove any sharp edges with fine-grit sandpaper to finish the process safely. With patience and the right approach, drilling through glass can be accomplished effectively without causing breakage.

Essential Considerations for Drilling Through Glass

- Tool Selection: Use carbide tip4 or diamond-coated drill bits.

- Marking and Taping: Ensure accurate placement and prevent slipping.

- Stability: Secure the glass firmly to avoid movement.

- Drill Speed: Maintain a low speed for better control.

- Pressure Application: Use steady, gentle pressure.

- Lubrication: Keep the area cool with water to prevent cracking.

- Edge Finishing: Smooth out any rough edges post-drilling.

Understanding and implementing these considerations will enable you to drill through glass successfully and safely.

Conclusion

Drilling glass is achievable with the right tools and techniques.

-

This link helps the reader understand the role of a non-permanent marker in marking precise points for drilling. ↩

-

Heat reduction is crucial to prevent cracking, especially when drilling through materials like glass. ↩

-

Diamond-coated bits are specifically designed for materials like glass or ceramics. ↩

-

Carbide tips are widely recognized for their durability and hardness, which makes them suitable for drilling tough materials like glass. ↩