Drilling glass can seem daunting, but with the right tools and techniques, it’s achievable.

Drilling glass requires the correct RPM, specialized drill bits, and careful handling to prevent cracks and breaks.

Don’t let the fear of breaking your glass stop you from creating perfect holes for your projects.

How Many RPM for Drilling Glass?

Drilling glass at the wrong RPM can lead to cracks and breakage.

The optimal RPM for drilling glass is between 500 to 1000 RPM to ensure smooth and precise holes without damage.

Understanding the right speed is crucial for successful glass drilling projects.

Choosing the Right Speed

Selecting the correct RPM1 is vital. Too high a speed can generate excessive heat, causing the glass to crack. Conversely, too low a speed may result in inefficient drilling and increased pressure on the glass.

Factors Affecting RPM Selection

- Glass Thickness: Thicker glass may require a slightly higher RPM within the safe range.

- Drill Bit Type: Carbide tip drill bits perform best within specific RPM ranges.

- Drill Power: More powerful drills can handle higher RPMs without compromising control.

Practical Tips for Maintaining Optimal RPM

- Use a Variable Speed Drill: This allows precise control over the drilling speed.

- Start Slow: Begin at a lower RPM and gradually increase as needed.

- Monitor the Process: Keep an eye on the drilling to adjust speed promptly if necessary.

RPM and Drill Bit Longevity

Maintaining the appropriate RPM not only protects the glass but also extends the life of your drill bits. Overheating from excessive speeds can dull carbide tips, reducing their effectiveness.

Table: Recommended RPM Settings

| Glass Thickness | Recommended RPM |

|---|---|

| Up to 1/4 inch | 500 – 700 RPM |

| 1/4 to 1/2 inch | 700 – 900 RPM |

| Over 1/2 inch | 900 – 1000 RPM |

How to Drill Holes in Glass: Easy Guide

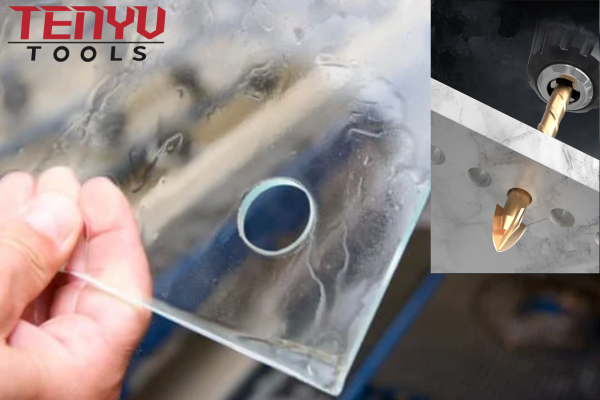

Drilling holes in glass is easier with the right steps and precautions.

Follow a step-by-step guide using proper tools and techniques to drill clean and precise holes in glass.

Mastering these steps will make your glass drilling projects successful and hassle-free.

Preparing Your Workspace

Before you begin, ensure your workspace2 is clean and free from any debris that could interfere with the drilling process. A stable surface is essential to maintain control over the drill and prevent accidents.

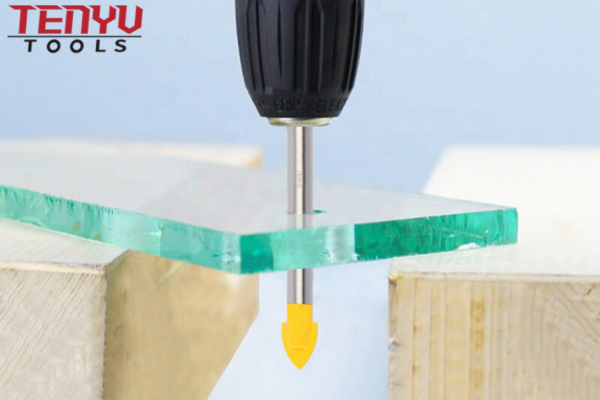

Selecting the Right Drill Bit

Using a carbide tip drill bit is crucial for drilling glass. These bits are designed to handle the hardness of glass without causing damage. Ensure your drill bit is sharp and in good condition to achieve the best results.

Marking the Drilling Spot

Accurately mark the spot where you want to drill. Using a marker or a piece of tape can help guide your drill and prevent slipping, which can cause cracks.

Applying Lubrication

Lubrication is essential to reduce heat buildup and minimize friction. You can use water or a specialized drilling lubricant to keep the drill bit cool and prolong its lifespan.

Drilling Technique

Start drilling at a low speed, applying gentle and consistent pressure. Let the drill bit do the work without forcing it, which can lead to breakage. Periodically lift the drill to allow cooling and prevent overheating.

Finishing the Hole

Once the hole is drilled, gently smooth the edges with a fine-grit sandpaper to remove any sharp edges. This step ensures the hole is clean and safe for your intended use.

Common Mistakes to Avoid

- Using the Wrong Drill Bit: Avoid standard bits; always use carbide tip bits for glass.

- Applying Too Much Pressure: Excessive force can crack the glass.

- Neglecting Lubrication: Failing to lubricate can cause overheating and damage.

Table: Step-by-Step Drilling Process

| Step | Description |

|---|---|

| 1. Prepare Workspace | Ensure a clean and stable surface |

| 2. Select Drill Bit | Use a carbide tip drill bit |

| 3. Mark Spot | Accurately mark the drilling location |

| 4. Apply Lubrication | Use water or drilling lubricant |

| 5. Start Drilling | Drill at low speed with gentle pressure |

| 6. Finish Hole | Smooth edges with fine-grit sandpaper |

| 7. Inspect | Check the hole for cleanliness and precision |

Which Drill Bit is Best for Drilling Glass?

Choosing the right drill bit is essential for successful glass drilling.

Carbide tip drill bits are the best choice for drilling glass due to their hardness and precision.

Selecting the right bit ensures clean holes and prevents damage to your glass projects.

Why Carbide Tip Drill Bits?

Carbide tip drill bits are specifically designed to handle hard materials like glass3. Their durability and precision make them ideal for creating clean and accurate holes without causing cracks or chips.

Features of Carbide Tip Drill Bits

- Hardness: Carbide is one of the hardest materials, allowing the bit to penetrate glass effortlessly.

- Precision: The sharp tips ensure accurate drilling, reducing the risk of slipping.

- Durability: These bits maintain their edge longer, providing consistent performance over multiple uses.

Comparing Carbide Tip Bits to Other Types

| Drill Bit Type | Suitability for Glass | Durability | Precision |

|---|---|---|---|

| Carbide Tip | Excellent | High | High |

| Diamond Core | Good | Moderate | Moderate |

| Standard Twist Bits | Poor | Low | Low |

How to Choose the Right Carbide Tip Drill Bit

When selecting a carbide tip drill bit, consider the following:

- Size: Choose the appropriate size for your hole requirements.

- Quality: Invest in high-quality bits to ensure longevity and performance.

- Compatibility: Ensure the bit is compatible with your drill for optimal results.

Maintaining Your Drill Bits

Proper maintenance extends the life of your carbide tip drill bits. Clean the bits after each use, store them in a dry place, and inspect for any signs of wear or damage regularly.

Table: Carbide Tip Drill Bit Specifications

| Specification | Description |

|---|---|

| Material | Carbide |

| Tip Angle | Typically 60 degrees for optimal drilling |

| Coating | Often coated for increased durability and reduced friction |

| Sizes Available | Range from small precision bits to larger sizes for bigger holes |

Practical Tips for Using Carbide Tip Drill Bits

- Start Slowly: Begin drilling at a low speed to ensure precision.

- Use Steady Pressure: Apply consistent pressure without forcing the drill.

- Keep It Cool: Regularly lubricate to prevent overheating and maintain bit integrity.

Can a Drill Bit Go Through Glass?

Yes, with the right tools and techniques, a drill bit can successfully go through glass.

Using the proper drill bit and careful drilling techniques ensures that the bit penetrates the glass without causing damage.

Achieving a clean hole in glass is possible when you follow the correct procedures and use the appropriate equipment.

Understanding Glass Composition

Glass is a brittle material composed mainly of silica, which makes it challenging to drill4. However, with the right approach, drilling through glass can be accomplished efficiently.

Selecting the Appropriate Drill Bit

As mentioned earlier, carbide tip drill bits are ideal for drilling glass. Their hardness allows them to penetrate the material without breaking.

Drilling Process

The drilling process involves several steps to ensure success:

- Mark the Spot: Clearly mark where you want to drill.

- Secure the Glass: Use clamps or a stable base to hold the glass firmly.

- Lubricate: Apply water or lubricant to keep the bit cool.

- Begin Drilling: Start at a low speed, applying steady pressure.

- Monitor Progress: Keep an eye on the drilling to adjust speed and pressure as needed.

- Finish Carefully: Once through, smooth the edges to prevent any sharpness.

Common Challenges and Solutions

- Cracking: Avoid excessive pressure and maintain a steady speed to prevent cracks.

- Slipping: Use a guide or tape to keep the drill bit in place.

- Overheating: Ensure adequate lubrication and avoid prolonged drilling without breaks.

Safety Precautions

Drilling glass requires attention to safety to prevent accidents:

- Wear Protective Gear: Safety glasses and gloves protect against shards.

- Work in a Controlled Environment: Ensure your workspace is clean and free from distractions.

- Handle Glass Carefully: Transport and position the glass gently to avoid unintended breaks.

Table: Troubleshooting Common Issues

| Issue | Cause | Solution |

|---|---|---|

| Cracking | Excessive pressure or speed | Reduce pressure and lower the RPM |

| Slipping | Unmarked or uneven drilling spot | Use a guide or tape to stabilize the bit |

| Overheating | Lack of lubrication | Apply water or lubricant regularly |

| Incomplete Hole | Insufficient drilling time | Continue drilling with steady pressure |

Final Thoughts on Drilling Through Glass

Successfully drilling through glass requires patience, the right tools, and careful technique. By following the proper steps and using carbide tip drill bits, you can achieve clean and precise holes for your glass projects.

Conclusion

Drilling glass is manageable with the right tools and techniques, ensuring precise and damage-free results.

-

RPM (Revolutions Per Minute) is a key concept in drilling and machining. ↩

-

"Workspace" is a critical element in the context of any manual task, and specifically, it’s vital when working with tools like drills. ↩

-

"glass" refers to a specific material that the carbide tip drill bits are designed to handle. ↩

-

"drilling tools" refers to specific tools needed for the task of drilling glass. ↩