Have you ever needed to make a hole in a glass bottle but didn’t have a drill?

You can make a hole in a glass bottle without a drill using Carbide Tip Drill bits and simple techniques.

Don’t worry if you lack specialized tools. Keep reading to discover effective methods.

How to Make a Hole In a Glass Bottle Without a Drill?

Have you found yourself needing to make a hole in a glass bottle but don’t have a drill?

You can successfully create a hole using Carbide Tip Drill bits and careful techniques.

Stay with me to learn the step-by-step process.

Making a Hole with Carbide Tip Drill Bits

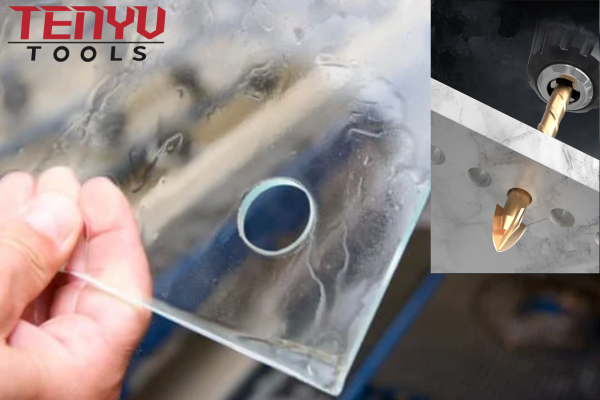

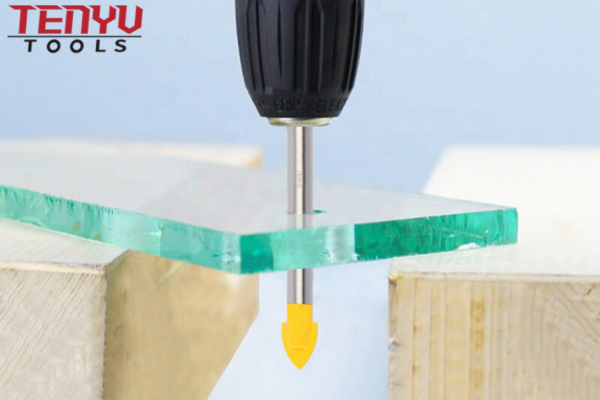

Creating a hole in a glass bottle without a traditional drill might seem challenging, but using Carbide Tip1 Drill bits makes it achievable. I remember the first time I needed to make a hole in a glass bottle for a DIY project. Without a drill, I felt stuck until I discovered Carbide Tip Drill bits. These bits are specifically designed to handle tough materials like glass. To start, gather your materials: a glass bottle, Carbide Tip Drill bits, masking tape, a marker, safety gloves, and eyewear. Begin by marking the spot where you want the hole with the marker. Apply masking tape over the mark to prevent the drill bit from slipping. Wearing your safety gear, carefully drill at a low speed, applying gentle pressure. The Carbide Tip ensures that the glass doesn’t crack or shatter under pressure. As you drill, keep the bottle wet to reduce heat and friction. Patience is key; rushing can lead to mistakes. Once the hole is made, smooth the edges with sandpaper for a clean finish. This method not only provides precision but also ensures safety throughout the process. Carbide Tip Drill bits are a reliable solution for glass projects, making them a valuable tool in any DIY enthusiast’s arsenal.

How are People Able to Cut Glass Without Shattering It?

Ever wondered how glass can be cut cleanly without breaking?

Experts use Carbide Tip Drill bits and precise techniques to make smooth cuts without shattering the glass.

Let’s explore the methods that ensure clean glass cuts every time.

Techniques for Cutting Glass Smoothly

Cutting glass without causing it to shatter involves understanding the properties of glass and using the right tools, like Carbide Tip Drill bits2. Glass is a brittle material, meaning it can break easily under stress. To cut it cleanly, one must minimize stress concentrations and apply even pressure. One effective method is scoring the glass. With a Carbide Tip Drill bit, you can create a precise score line. Start by marking the desired cut line using a marker. Place masking tape along the line to provide additional support. Using the Carbide Tip, gently drill along the marked line at a low speed. The carbide tip helps to create a controlled weakness in the glass without causing cracks to propagate uncontrollably. After scoring, carefully bend the glass along the line. The score acts as a guide, allowing the glass to break cleanly. Another technique involves using Carbide Tip Drill bits to make multiple small holes along the cut line. These holes help to distribute the stress evenly, preventing shattering. Additionally, maintaining a steady hand and consistent speed while drilling is crucial. Keeping the glass wet during the process helps to reduce heat buildup and friction, further preventing cracks. By using Carbide Tip Drill bits and these precise techniques, you can achieve smooth and clean cuts in glass without the risk of shattering.

Advantages of Using Carbide Tip Drill Bits

Using Carbide Tip Drill bits offers several advantages when working with glass. Firstly, the hardness of carbide allows it to effectively cut through glass without dulling quickly. This ensures that each drill bit remains sharp and effective for multiple uses. Secondly, Carbide Tip Drill bits provide greater precision. The pointed carbide tip can create more accurate holes, which is essential for projects requiring exact measurements. Additionally, these drill bits generate less heat compared to standard bits, reducing the risk of glass cracking due to thermal stress. The durability of carbide means that the drill bits can withstand the abrasive nature of glass, making them a cost-effective choice in the long run. Moreover, Carbide Tip Drill bits are versatile. They can be used not only for drilling but also for scoring and cutting glass, making them a multifunctional tool in your workshop. Their ability to maintain sharpness and precision over time makes them indispensable for both amateur DIYers and professional glassworkers. Investing in Carbide Tip Drill bits can significantly improve the quality and safety of your glass projects.

Comparison Table: Carbide Tip vs. Other Drill Bits

| Feature | Carbide Tip Drill Bits | Standard High-Speed Steel (HSS) Bits | Diamond-Tipped Bits |

|---|---|---|---|

| Durability | Very high | Moderate | High |

| Precision | Excellent | Good | Excellent |

| Heat Resistance | High | Low | High |

| Material Compatibility | Glass, ceramic, metal | Primarily metal | Glass, ceramic |

| Cost | Moderate | Low | High |

| Lifespan | Long | Short | Long |

How to Cut Glass Without a Glass Cutter and Without a Laser?

Need to cut glass but don’t have a cutter or laser?

You can cut glass using Carbide Tip Drill bits and alternative household items with the right techniques.

Discover easy and effective methods to achieve precise glass cuts.

Alternative Methods for Cutting Glass

Cutting glass without a traditional glass cutter or laser is possible with the help of Carbide Tip Drill bits and some ingenuity. One method involves creating a score line using a Carbide Tip Drill bit. Begin by marking the desired cut line on the glass with a marker. Apply masking tape along the line to prevent slipping. Using the Carbide Tip Drill bit, gently drill along the marked line at a low speed. The carbide tip helps to create a controlled score without causing the glass to shatter. After scoring, place the glass on a flat surface with the scored line aligned over the edge. Apply gentle pressure to snap the glass along the score. Another technique uses a string or dental floss3 soaked in rubbing alcohol. Lay the string along the cut line and use the Carbide Tip Drill bit to make small holes along the string. Gradually, the string will weaken the glass, allowing you to snap it cleanly. Additionally, heating the glass along the cut line with a candle and then cooling it rapidly can create a thermal shock that breaks the glass along the desired line. However, this method requires caution to prevent accidental breaks. Throughout these processes, using Carbide Tip Drill bits ensures that the glass is cut accurately and safely. Always wear protective gloves and eyewear to guard against any accidental shards. These alternative methods, combined with Carbide Tip Drill bits, provide effective solutions for cutting glass without specialized tools.

Step-by-Step Guide to Using Carbide Tip Drill Bits

Using Carbide Tip Drill bits for cutting glass without specialized tools involves several careful steps. Here’s a detailed guide to help you through the process:

-

Gather Materials: You will need a glass bottle or sheet, Carbide Tip Drill bits, masking tape, a marker, safety gloves, and eyewear.

-

Mark the Cut Line: Use the marker to clearly indicate where you want to make the hole or cut.

-

Apply Masking Tape: Place masking tape along the marked line. This helps prevent the drill bit from slipping and provides additional support to the glass.

-

Prepare the Drill: Insert the Carbide Tip Drill bit into your drill. Set the drill to a low speed to maintain control and reduce heat buildup.

-

Start Drilling: Begin drilling at the marked spot, applying gentle and steady pressure. Keep the drill perpendicular to the glass surface to ensure a straight hole.

-

Maintain Lubrication: Continuously apply water to the drilling area. This acts as a lubricant and helps dissipate heat, reducing the risk of cracking.

-

Create the Score Line: For cutting, make a shallow score along the desired cut line using the Carbide Tip Drill bit. Ensure the score is consistent and even.

-

Snap the Glass: Once the score line is established, place the glass on a flat surface with the score aligned over the edge. Apply gentle pressure to snap the glass along the score.

-

Smooth the Edges: After making the hole or cut, use fine-grit sandpaper to smooth any rough edges for a clean finish.

-

Safety Check: Inspect the glass for any remaining sharp edges or cracks. Ensure that the hole or cut is clean and safe to handle.

By following these steps and utilizing Carbide Tip Drill bits, you can achieve precise and clean holes or cuts in glass without the need for specialized tools. This method is not only effective but also ensures safety and durability in your glass projects.

Personal Experience with Carbide Tip Drill Bits

When I first started working on glass projects, I struggled with finding the right tools to make clean cuts and holes. Traditional drill bits often left the glass cracked or shattered, making the process frustrating and time-consuming. It wasn’t until I discovered Carbide Tip Drill bits that everything changed. I decided to create a decorative glass vase with intricate holes without a drill. Using Carbide Tip Drill bits, I was able to drill precise holes without damaging the glass. The carbide tips provided the necessary precision and durability, allowing me to work efficiently and safely. The process was smooth, and the results were exactly what I envisioned. This experience taught me the value of using the right tools for glasswork. Carbide Tip Drill bits not only improved the quality of my projects but also gave me the confidence to tackle more complex designs. Whether you’re a DIY enthusiast or a professional, investing in Carbide Tip Drill bits can make a significant difference in your glass cutting and drilling tasks.

Common Mistakes to Avoid

When using Carbide Tip Drill bits for cutting or drilling glass, certain mistakes can lead to poor results or even accidents. Here are some common pitfalls and how to avoid them:

-

Using High Speed: Drilling glass at high speeds generates excessive heat, which can cause the glass to crack or shatter. Always use a low-speed setting to maintain control and reduce heat buildup.

-

Applying Excessive Pressure: Pressing too hard on the drill can lead to uneven cuts and increase the risk of breaking the glass. Apply gentle, steady pressure to allow the Carbide Tip Drill bit to do the work.

-

Skipping Lubrication: Failing to keep the drilling area wet can cause friction and heat, damaging both the glass and the drill bit. Continuously apply water to lubricate and cool the glass during the process.

-

Incorrect Alignment: Drilling at an angle can result in crooked holes and weaken the glass structure. Ensure the drill is perpendicular to the glass surface for straight and precise holes.

-

Neglecting Safety Gear: Not wearing protective gloves and eyewear exposes you to potential glass shards and sharp edges. Always wear appropriate safety gear to protect yourself.

-

Poor Marking: Inaccurate marking of the cut or drill location can lead to mistakes and uneven results. Use a clear marker and masking tape to ensure precise placement.

-

Not Securing the Glass: Allowing the glass to move during drilling can cause slips and uneven cuts. Secure the glass firmly on a stable surface to maintain control throughout the process.

-

Overlooking Edge Finishing: Ignoring the smoothing of drilled or cut edges can leave sharp, dangerous points. Always finish the edges with sandpaper to ensure they are safe to handle.

By being aware of these common mistakes and taking steps to avoid them, you can ensure a successful and safe glass cutting or drilling experience using Carbide Tip Drill bits.

Tips on Drilling Through Glass!

Looking to drill through glass without causing damage?

Proper techniques and Carbide Tip Drill bits can help you drill through glass smoothly and safely.

Learn essential tips to achieve successful glass drilling.

Essential Tips for Drilling Through Glass

Drilling through glass requires careful preparation and the right techniques to prevent cracking or shattering. One of the most effective tools for this task is the Carbide Tip Drill bit. Here’s how to use it successfully:

-

Choose the Right Drill Bit: Carbide Tip Drill bits are ideal for glass as they provide the necessary precision and durability. Their hard carbide tips can penetrate glass without dulling quickly, ensuring clean holes every time.

-

Prepare the Glass: Start by cleaning the glass surface to remove any dirt or debris that could interfere with the drilling process. Mark the exact spot where you want to drill using a marker for accuracy.

-

Secure the Glass: Place the glass on a stable, flat surface. Use clamps or a vise to secure it firmly, ensuring it doesn’t move during drilling. Stability is crucial to prevent accidental slips.

-

Apply Lubrication: Wet the drilling area with water. Lubrication helps reduce friction and heat buildup, which can cause the glass to crack. You can also use a mixture of water and a few drops of dish soap for better lubrication.

-

Start Drilling: Insert the Carbide Tip Drill bit into your drill. Set the drill to a low speed to maintain control. Begin drilling at a slight angle to create a starting point, then gradually bring the drill perpendicular to the glass surface.

-

Maintain Steady Pressure: Apply gentle, steady pressure as you drill. Let the Carbide Tip do the work without forcing the drill. Consistent pressure helps create a clean hole and minimizes the risk of cracking.

-

Cool the Glass: Periodically pause to add more water to the drilling area. This helps keep the glass cool and reduces the chances of thermal stress, which can lead to cracks.

-

Finish the Hole: Once you’ve drilled through the glass, carefully remove the drill bit. Smooth any rough edges around the hole with fine-grit sandpaper to ensure safety and a professional finish.

-

Safety First: Always wear protective gloves and eyewear when drilling glass. Glass shards and sharp edges can pose serious hazards, so safety gear4 is essential.

-

Practice Patience: Drilling glass takes time and patience. Rushing the process can lead to mistakes and damaged glass. Take your time to ensure each step is done correctly.

By following these tips and using Carbide Tip Drill bits, you can drill through glass smoothly and safely, achieving professional results in your projects.

Maintaining Your Carbide Tip Drill Bits

To ensure your Carbide Tip Drill bits remain effective and last longer, proper maintenance is essential. Here are some tips to keep your drill bits in top condition:

-

Clean After Use: After drilling, clean the Carbide Tip Drill bits thoroughly to remove any glass residue or debris. Use a soft brush and mild detergent to gently scrub the bits, then rinse with water and let them dry completely.

-

Store Properly: Store your drill bits in a dry, clean place to prevent rust and damage. Using a protective case or holder can keep them organized and easily accessible.

-

Inspect Regularly: Before each use, inspect your drill bits for any signs of wear or damage. Look for chips, cracks, or dull tips. Damaged bits should be replaced immediately to ensure safe and effective drilling.

-

Sharpen When Necessary: Over time, Carbide Tip Drill bits may become dull. Sharpen them using a carbide sharpening stone or take them to a professional sharpening service. Keeping the tips sharp ensures precise drilling and reduces the risk of glass damage.

-

Avoid Overheating: Excessive heat can dull the carbide tips. Always use lubrication and drill at low speeds to minimize heat buildup. Allow the drill bits to cool down between uses if they become hot during drilling.

-

Use Proper Technique: Applying the correct drilling technique reduces wear on the drill bits. Avoid applying excessive pressure and maintain a steady speed to prolong the life of your Carbide Tip Drill bits.

-

Rotate Drill Bits: If you notice uneven wear on the drill bits, rotate them regularly to ensure even usage. This can extend the lifespan of each bit and maintain their effectiveness.

-

Handle with Care: Treat your drill bits gently to avoid bending or breaking the carbide tips. Dropping or mishandling the bits can cause irreversible damage, rendering them unusable.

-

Limit Use on Hard Materials: While Carbide Tip Drill bits are durable, excessive use on extremely hard materials beyond their intended purpose can cause wear. Use them primarily for glass and similar materials to maintain their integrity.

-

Regular Replacement: Even with proper maintenance, Carbide Tip Drill bits will eventually wear out. Keep a set of spare bits on hand to ensure you can continue your projects without interruption.

By maintaining your Carbide Tip Drill bits properly, you ensure they remain effective and safe for all your glass drilling needs. Proper care not only extends the life of the bits but also guarantees consistent, high-quality results in your projects.

Safety Precautions When Drilling Glass

Drilling glass can be hazardous if proper safety measures are not followed. Here are essential safety precautions to keep in mind:

-

Wear Protective Gear:

- Gloves: Protect your hands from sharp edges and accidental glass shards.

- Safety Glasses: Shield your eyes from flying debris and fragments.

- Long Sleeves: Wear long sleeves to protect your arms from potential splinters.

-

Secure the Glass Properly:

- Use clamps or a vise to hold the glass firmly in place. This prevents movement that can lead to slips and accidents.

-

Work in a Well-Ventilated Area:

- Drilling can produce dust and small glass particles. Ensure you’re in a space with good airflow to avoid inhaling these particles.

-

Use Masking Tape:

- Apply masking tape to the drilling spot to provide additional grip for the drill bit and reduce the risk of slipping.

-

Keep the Drilling Area Wet:

- Continuously apply water to the drilling area to minimize heat buildup and reduce the risk of cracking. Wet drilling also helps control dust.

-

Maintain a Low-Speed Setting:

- High speeds can generate excessive heat and cause the glass to crack. Use a low-speed setting to maintain control and reduce heat.

-

Avoid Overloading the Drill:

- Let the Carbide Tip Drill bit do the work without applying too much pressure. Overloading can damage the glass and the drill bit.

-

Inspect Your Tools:

- Before starting, check the Carbide Tip Drill bit for any signs of damage or wear. A damaged bit can lead to poor performance and increased risk of accidents.

-

Work Slowly and Steadily:

- Rushing the drilling process increases the likelihood of mistakes and accidents. Take your time to ensure each step is done correctly.

-

Have a First Aid Kit Nearby:

- In case of minor injuries, having a first aid kit within reach can provide immediate assistance.

-

Dispose of Glass Waste Properly:

- Collect any glass shards and dispose of them safely to prevent injury to yourself and others.

-

Stay Focused:

- Avoid distractions while drilling. Staying focused helps maintain control and reduces the risk of accidents.

-

Use a Stable Surface:

- Ensure the surface you’re working on is stable and level to prevent the glass from slipping or tipping over during drilling.

-

Check for Hidden Cracks:

- Inspect the glass for any pre-existing cracks that could worsen during drilling. Using undamaged glass ensures better results and safety.

-

Take Breaks if Needed:

- If you feel fatigued, take a break to maintain concentration and reduce the risk of mistakes.

By adhering to these safety precautions, you can minimize risks and ensure a safe and successful glass drilling experience using Carbide Tip Drill bits. Safety should always be your top priority when working with glass and power tools.

Troubleshooting Common Issues

Even with the best tools and techniques, you might encounter some issues while drilling glass. Here are common problems and how to troubleshoot them:

-

Drill Bit Skipping or Sliding:

- Solution: Ensure the drill bit is sharp and properly secured in the drill. Use masking tape to mark the drilling spot and provide grip for the drill bit.

-

Glass Cracking During Drilling:

- Solution: Reduce the drilling speed and apply less pressure. Make sure the glass is well-lubricated with water to minimize heat and friction.

-

Uneven Holes:

- Solution: Keep the drill perpendicular to the glass surface and maintain steady pressure. Use a guide or jig to help keep the drill straight.

-

Drill Bit Overheating:

- Solution: Pause periodically to cool the drill bit and add more water to the drilling area. Ensure you’re using a low-speed setting.

-

Difficulty Starting the Hole:

- Solution: Begin drilling at a slight angle to create a groove, then gradually straighten the drill as the bit penetrates the glass.

-

Glass Shattering After Drilling:

- Solution: Ensure the glass is properly secured and stabilized. Use Carbide Tip Drill bits to create a controlled score and reduce stress on the glass.

-

Inconsistent Hole Sizes:

- Solution: Maintain consistent speed and pressure throughout the drilling process. Ensure the drill bit is aligned correctly from start to finish.

-

Excessive Noise or Vibration:

- Solution: Check that the drill bit is properly secured and not damaged. Ensure the glass is stable and not moving during drilling.

-

Drill Bit Getting Stuck in the Glass:

- Solution: Stop drilling and gently wiggle the drill bit to free it. Add more water to the drilling area to reduce friction.

-

Rough or Jagged Edges:

- Solution: After drilling, use fine-grit sandpaper or a glass file to smooth out any rough edges for a clean finish.

-

Hole Not Completely Through:

- Solution: Continue drilling gently until the hole is fully penetrated. Ensure the drill bit remains steady and aligned.

-

Difficulty Removing the Drill Bit:

- Solution: Pause drilling and apply more lubrication. Gently wiggle the drill bit to loosen it from the glass.

By understanding these common issues and their solutions, you can effectively troubleshoot problems that arise while drilling glass. This ensures a smoother process and better results when using Carbide Tip Drill bits for your glass projects.

Choosing the Right Carbide Tip Drill Bit

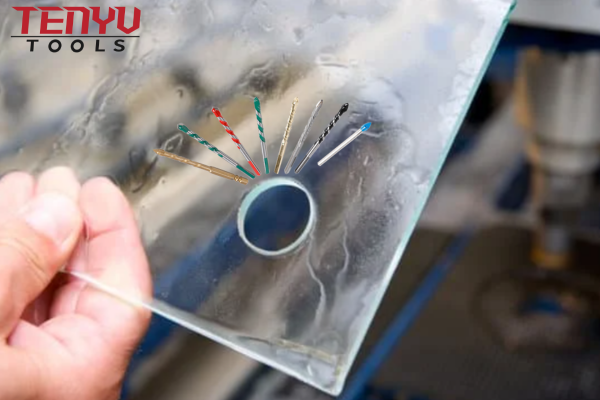

Selecting the appropriate Carbide Tip Drill bit is crucial for the success of your glass drilling projects. Here are factors to consider when choosing the right bit:

-

Size of the Hole:

- Consideration: Determine the diameter of the hole you need. Carbide Tip Drill bits come in various sizes, so choose one that matches your project requirements.

- Tip: For larger holes, consider using a step drill bit or a bit with a wider carbide tip to ensure smooth drilling.

-

Type of Glass:

- Consideration: Different types of glass may require different drill bits. Tempered glass, for example, is more resistant and may need a more robust Carbide Tip Drill bit.

- Tip: For regular glass bottles or sheets, standard Carbide Tip Drill bits are sufficient. For specialized glass, consult with a supplier for the best option.

-

Drilling Purpose:

- Consideration: The intended use of the hole affects the type of drill bit you choose. Decorative holes may require more precision, while functional holes need durability.

- Tip: For decorative purposes, opt for finer Carbide Tip Drill bits that offer higher precision and cleaner finishes.

-

Drill Compatibility:

- Consideration: Ensure the Carbide Tip Drill bit is compatible with your drill. Check the shank size and type to match your drill’s chuck.

- Tip: Most Carbide Tip Drill bits are designed to fit standard drills, but verifying compatibility can prevent issues during drilling.

-

Bit Length:

- Consideration: The length of the drill bit should match the thickness of the glass you’re working with. Longer bits are needed for thicker glass.

- Tip: Measure the glass thickness before selecting a drill bit to ensure it can penetrate without issues.

-

Quality of the Carbide Tip:

- Consideration: Higher quality Carbide Tip Drill bits offer better performance and longevity.

- Tip: Invest in reputable brands that guarantee the hardness and durability of their Carbide Tip Drill bits.

-

Cost and Budget:

- Consideration: Carbide Tip Drill bits vary in price based on quality and size.

- Tip: While higher quality bits may cost more, they offer better performance and last longer, providing better value in the long run.

-

Special Features:

- Consideration: Some Carbide Tip Drill bits come with additional features like self-lubricating coatings or specific geometries for improved performance.

- Tip: Look for features that enhance drilling efficiency and safety, such as spiral flutes for better debris removal.

-

Supplier Reputation:

- Consideration: Purchase Carbide Tip Drill bits from reputable suppliers to ensure quality and reliability.

- Tip: Check reviews and seek recommendations from other glassworking professionals to find trusted suppliers.

-

Availability of Replacement Parts:

- Consideration: Ensure that replacement Carbide Tip Drill bits are readily available for future projects.

- Tip: Choose suppliers that offer a wide range of sizes and types to accommodate different drilling needs.

By carefully considering these factors, you can select the right Carbide Tip Drill bit for your glass drilling projects, ensuring efficiency, precision, and safety in your work.

Enhancing Efficiency with Carbide Tip Drill Bits

Maximizing efficiency when drilling glass can save time and improve the quality of your projects. Here are strategies to enhance your efficiency using Carbide Tip Drill bits:

-

Organize Your Workspace:

- Strategy: Keep your tools and materials organized and within easy reach. A clutter-free workspace minimizes the time spent searching for tools and reduces the risk of accidents.

- Benefit: Streamlines the drilling process and allows you to focus on precision.

-

Use a Drill Press:

- Strategy: Invest in a drill press for more controlled and consistent drilling. A drill press maintains a steady angle and speed, enhancing accuracy.

- Benefit: Reduces hand fatigue and increases drilling precision, especially for repetitive tasks.

-

Pre-Mark Multiple Drill Points:

- Strategy: If you need to drill multiple holes, mark all the points beforehand. This allows you to work systematically without stopping to measure each time.

- Benefit: Saves time and ensures consistent spacing between holes.

-

Maintain Drill Bits Regularly:

- Strategy: Keep your Carbide Tip Drill bits clean and sharp. Regular maintenance prevents slow drilling and ensures clean holes.

- Benefit: Extends the lifespan of your drill bits and maintains drilling efficiency.

-

Use Templates for Repetitive Designs:

- Strategy: Create or purchase templates for designs that require multiple holes. Templates guide the drill bit, ensuring uniformity.

- Benefit: Enhances consistency and speeds up the drilling process for complex or repetitive patterns.

-

Implement a Water Cooling System:

- Strategy: Use a drip system or a spray bottle to continuously apply water to the drilling area. Consistent lubrication reduces heat and friction.

- Benefit: Prevents glass cracking and extends the life of your Carbide Tip Drill bits, allowing for longer drilling sessions without interruptions.

-

Batch Processing:

- Strategy: Group similar drilling tasks together. Complete all drilling for one project before moving to the next.

- Benefit: Increases focus and reduces the time lost in switching between different tasks or projects.

-

Use Proper Lighting:

- Strategy: Ensure your workspace is well-lit. Good lighting helps you see markings and align the drill accurately.

- Benefit: Reduces errors and improves the quality of your drilling work.

-

Develop a Drilling Routine:

- Strategy: Establish a consistent routine for setting up and drilling. This can include steps like cleaning the glass, applying tape, and lubricating.

- Benefit: Creates a streamlined process that enhances efficiency and reduces the likelihood of missing steps.

-

Train and Practice:

- Strategy: Regularly practice drilling techniques to improve your speed and accuracy. Training yourself to handle Carbide Tip Drill bits effectively can make a significant difference.

- Benefit: Increases proficiency, allowing you to complete projects faster without compromising quality.

-

Use Multi-functional Tools:

- Strategy: Incorporate tools that serve multiple purposes, such as drill bit sharpeners or adjustable clamps.

- Benefit: Reduces the need for multiple tools, saving space and time.

-

Plan Your Projects:

- Strategy: Before starting, plan the sequence of drilling and identify any potential challenges. Having a clear plan helps in executing tasks efficiently.

- Benefit: Prevents delays and ensures a smooth workflow throughout the project.

-

Optimize Drill Settings:

- Strategy: Experiment with different drill speeds and settings to find the most efficient combination for your specific glass type and thickness.

- Benefit: Enhances drilling speed and reduces the risk of errors, improving overall efficiency.

-

Leverage Technology:

- Strategy: Use digital markers or laser guides to enhance precision and speed in marking and drilling.

- Benefit: Increases accuracy and reduces the time spent on manual alignment.

-

Stay Organized with Inventory Management:

- Strategy: Keep track of your Carbide Tip Drill bits and other supplies. Use labels or inventory software to monitor stock levels.

- Benefit: Ensures you have the necessary tools on hand, preventing project delays due to missing or worn-out bits.

By implementing these strategies, you can significantly enhance your efficiency when drilling glass with Carbide Tip Drill bits. Efficient workflows not only save time but also improve the quality and consistency of your glass projects.

Environmental Impact

Using Carbide Tip Drill bits also has positive implications for the environment:

-

Reduced Waste:

- Impact: Longer-lasting drill bits mean fewer replacements, leading to less manufacturing waste.

- Benefit: Lower environmental footprint due to reduced material consumption.

-

Energy Efficiency:

- Impact: Efficient drilling reduces energy consumption, contributing to lower carbon emissions.

- Benefit: More sustainable operations with reduced energy usage.

-

Durable Materials:

- Impact: Carbide is a durable material that can be recycled.

- Benefit: Promotes recycling and reduces landfill waste when drill bits reach the end of their lifespan.

-

Minimized Glass Waste:

- Impact: Precise drilling reduces the amount of broken or wasted glass.

- Benefit: Conserves resources and decreases the need for additional glass production.

-

Longer Product Life:

- Impact: High-quality projects last longer, reducing the need for frequent replacements.

- Benefit: Promotes sustainability by extending the lifecycle of products.

By choosing Carbide Tip Drill bits, you contribute to environmentally friendly practices through reduced waste, energy efficiency, and sustainable material usage. This aligns with broader goals of sustainability and responsible resource management, making Carbide Tip Drill bits not only a cost-effective choice but also an environmentally conscious one.

Conclusion

Creating holes in glass bottles without specialized tools is achievable with Carbide Tip Drill bits and the right techniques.

-

Carbide Tip Drill bits are the key tool for drilling into tough materials like glass. ↩

-

Carbide Tip Drill bits are mentioned as the key tool in cutting glass without shattering. ↩

-

The use of string or dental floss is an unconventional method for cutting glass. ↩

-

Safety is emphasized in the article, so linking to a source that covers the importance and types of protective equipment ↩