Have you ever struggled to find reliable HSS drill bits for your metalworking projects?

Discover the top 10 HSS drill bit factories in America that deliver quality and precision for all your drilling needs.

Keep reading to explore the best manufacturers and enhance your metalworking efficiency.

TENYU TOOLS

As a leading manufacturer in China, TENYU TOOLS stands out in the American market for its exceptional HSS drill bits.

TENYU TOOLS offers a wide range of high-quality drill bits, customizable to meet specific client needs with competitive pricing.

Their commitment to excellence ensures that businesses receive reliable and precise tools for all their drilling applications.

Product Range and Features

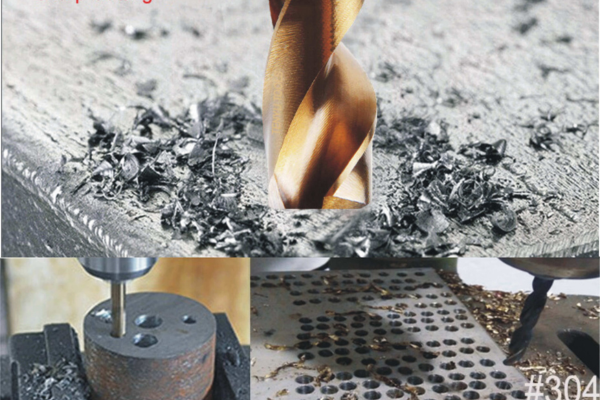

TENYU TOOLS specializes in various drill bits1, including twist, step, and cobalt variants, all designed for durability and performance. Their products are crafted using premium materials, ensuring longevity even under heavy use.

H3: Customization Options

Clients can customize drill bits with their logos, making TENYU TOOLS a preferred partner for businesses looking to brand their tools. This feature not only enhances brand visibility but also strengthens client relationships by providing personalized products.

H3: Quality Assurance

With ISO and CE certifications, TENYU TOOLS guarantees that each drill bit meets stringent quality standards. Their 15 production lines are equipped with advanced machinery, ensuring consistency and precision in every batch.

Customer Support and Services

TENYU TOOLS offers excellent customer support, assisting clients with product selection, customization, and after-sales service. Their dedication to customer satisfaction makes them a trusted supplier in the B2B market.

Chicago Latrobe

Chicago Latrobe is renowned for its robust and reliable HSS drill bits, catering to various industrial needs across America.

Chicago Latrobe’s drill bits are engineered for precision and durability, making them a top choice for professionals in the metalworking industry.

Their extensive product lineup and commitment to quality set them apart in a competitive market.

Product Innovations

Chicago Latrobe continuously innovates to improve the efficiency and performance of their drill bits. Their R&D team focuses on developing advanced coatings2 and geometries that enhance cutting speed and reduce wear.

H3: Specialized Drill Bits

They offer specialized drill bits for specific applications, such as high-speed drilling and deep hole drilling, ensuring that clients have the right tool for every task.

H3: Sustainable Practices

Chicago Latrobe integrates sustainable manufacturing practices, minimizing waste and reducing environmental impact while maintaining high product standards.

Market Presence

With a strong presence in North America, Chicago Latrobe partners with major distributors and suppliers, ensuring widespread availability of their products and reliable delivery schedules.

Dormer Pramet

Dormer Pramet is a global leader in precision drill bits, offering a diverse range of HSS products tailored to meet various industrial demands.

Dormer Pramet’s HSS drill bits are synonymous with quality and precision, trusted by industries worldwide for their performance and reliability.

Their innovative designs and extensive product offerings make them a preferred supplier for many large companies and hardware distributors.

Advanced Manufacturing

Dormer Pramet utilizes state-of-the-art manufacturing processes to produce drill bits that meet the highest standards of quality and performance. Their commitment to innovation3 ensures that their products remain at the forefront of the industry.

H3: Product Customization

They offer extensive customization options, allowing clients to specify dimensions, coatings, and other features to suit their unique requirements.

H3: Comprehensive Product Line

Dormer Pramet provides a wide array of drill bits, including specialized types for high-precision tasks, ensuring that clients have access to the best tools for their specific applications.

Global Reach

With a strong international presence, Dormer Pramet serves clients across North America, Japan, and Singapore, ensuring timely delivery and excellent customer service worldwide.

Guhring

Guhring is renowned for its high-performance HSS drill bits, catering to the needs of professionals in the metalworking and manufacturing sectors.

Guhring’s drill bits are engineered for maximum efficiency and longevity, making them a top choice for demanding drilling applications.

Their focus on quality and innovation ensures that their products consistently meet the highest industry standards.

Technology and Innovation

Guhring invests heavily in research and development to create advanced drill bit designs that enhance performance and extend tool life. Their innovative approach results in products that offer superior cutting speeds4 and reduced wear.

H3: Precision Engineering

Each drill bit undergoes rigorous testing and quality control to ensure precision and reliability, making them ideal for high-stakes industrial applications.

H3: Versatile Applications

Guhring’s extensive product range includes drill bits for various materials, including hardened steel and stainless steel, providing versatility for different project requirements.

Customer Commitment

Guhring is committed to providing exceptional customer service, offering technical support and guidance to help clients select the right drill bits for their specific needs.

KnKut

KnKut is a trusted name in the hardware industry, known for its durable and high-quality HSS drill bits.

KnKut’ HSS drill bits are built to withstand tough conditions, offering reliability and performance for both professional and DIY projects.

Their reputation for quality makes them a preferred choice among hardware distributors and large company buyers.

Durable Construction

KnKut uses high-grade materials5 and precise manufacturing processes to produce drill bits that are both strong and long-lasting. Their products are designed to handle heavy use without compromising on performance.

H3: Comprehensive Selection

They offer a wide selection of drill bits, including standard, brad, and cobalt types, catering to various drilling needs and applications.

H3: Ergonomic Design

KnKut incorporates ergonomic designs in their drill bits, ensuring ease of use and reducing user fatigue during extended drilling sessions.

Strong Distribution Network

With a robust distribution network, KnKut ensures that their HSS drill bits are readily available to customers across North America and beyond, providing reliable access to their high-quality products.

OSG

OSG is a global leader in cutting tools, offering a wide range of HSS drill bits known for their precision and durability.

OSG’s HSS drill bits are engineered for high-performance drilling, making them a top choice for industrial applications and heavy-duty projects.

Their commitment to quality and innovation ensures that their products meet the diverse needs of their global clientele.

Precision Manufacturing

OSG employs advanced manufacturing techniques to produce drill bits6 with exact specifications and superior tolerances. This precision ensures consistent performance and reliability across all their products.

H3: Specialized Coatings

OSG offers drill bits with specialized coatings that enhance hardness, reduce friction, and extend tool life, providing superior performance in demanding drilling conditions.

H3: Diverse Product Range

Their extensive product range includes various types of HSS drill bits, each designed to meet specific drilling requirements and applications, ensuring that clients have access to the right tool for every task.

Global Presence

With a strong presence in major markets like North America, Japan, and Singapore, OSG ensures that their high-quality drill bits are accessible to customers worldwide, supported by efficient distribution and excellent customer service.

YG-1

YG-1 is a reputable manufacturer of HSS drill bits, known for their high quality and competitive pricing in the American market.

YG-1’s drill bits offer exceptional performance and durability, making them a reliable choice for both industrial and commercial drilling applications.

Their focus on quality and customer satisfaction sets them apart in a crowded marketplace.

Quality and Affordability

YG-1 balances quality and affordability, providing high-performance drill bits at competitive prices. This makes their products accessible to a wide range of customers without compromising on quality7.

H3: Range of Products

They offer a comprehensive range of HSS drill bits, including standard twist bits, cobalt bits, and specialty bits, catering to various drilling needs and applications.

H3: Reliable Performance

YG-1’s drill bits are designed to deliver consistent performance, ensuring that users can rely on them for precise and efficient drilling every time.

Strong Customer Relationships

YG-1 builds strong relationships with their clients by offering excellent customer service, timely deliveries, and responsive support, ensuring customer satisfaction and loyalty.

Greenfield Industries

Greenfield Industries is a prominent supplier of HSS drill bits, known for their robust construction and superior performance in the American market.

Greenfield Industries’ drill bits are designed for longevity and efficiency, making them a trusted choice for industrial and commercial applications.

Their dedication to quality and innovation ensures that their products meet the highest industry standards.

Robust Construction

Greenfield Industries uses high-quality materials and stringent manufacturing processes8 to produce drill bits that are both durable and reliable, capable of withstanding heavy use without compromising performance.

H3: Innovative Designs

They continuously develop innovative drill bit designs that enhance cutting efficiency and reduce wear, ensuring that their products remain at the forefront of the industry.

H3: Comprehensive Support

Greenfield Industries provides comprehensive support to their customers, including technical guidance and after-sales service, ensuring that clients get the most out of their products.

Extensive Distribution Network

With a well-established distribution network, Greenfield Industries ensures that their HSS drill bits are readily available to customers across North America, supported by efficient logistics and reliable delivery services.

MBA USA

MBA USA is a leading manufacturer of high-quality HSS drill bits, serving the American market with precision-engineered tools.

MBA USA’s HSS drill bits are crafted for excellence, offering reliability and performance for a wide range of drilling applications.

Their focus on quality manufacturing and customer satisfaction makes them a preferred supplier for many businesses.

Precision Engineering

MBA USA employs advanced engineering techniques to produce drill bits9 with exact specifications and superior precision, ensuring consistent and reliable performance in every use.

H3: Diverse Product Offerings

They offer a wide variety of HSS drill bits, including specialized types for high-precision tasks and heavy-duty applications, catering to the diverse needs of their clients.

H3: Quality Control

MBA USA implements rigorous quality control measures throughout the manufacturing process, ensuring that each drill bit meets the highest standards of quality and performance.

Strong Market Presence

With a strong presence in key markets like North America, MBA USA ensures that their high-quality drill bits are accessible to a broad range of customers, supported by excellent distribution and customer service.

Bad Dog Tools

Bad Dog Tools is a respected name in the HSS drill bit industry, known for their durable and high-performance products in the American market.

Bad Dog Tools’ HSS drill bits are built to last, offering exceptional cutting power and reliability for demanding drilling tasks.

Their commitment to quality and innovation ensures that their products consistently meet the needs of their customers.

Durable and Reliable

Bad Dog Tools focuses on producing drill bits that are both durable and reliable, capable of handling tough drilling conditions without sacrificing performance.

H3: Innovative Features

Their drill bits incorporate innovative features such as advanced coatings10 and specialized geometries, enhancing cutting efficiency and extending tool life.

H3: Comprehensive Product Range

Bad Dog Tools offers a comprehensive range of HSS drill bits, including various types and sizes to accommodate different drilling requirements and applications.

Customer-Centric Approach

Bad Dog Tools prioritizes customer satisfaction by providing excellent service, timely deliveries, and responsive support, ensuring that clients receive the best possible experience with their products.

How to drill a hole in hardened steel?

Feeling frustrated when your drill bit won’t penetrate hardened steel?

Drilling a hole in hardened steel requires the right technique and quality HSS drill bits to ensure success.

Let me guide you through the process to make your drilling tasks easier and more efficient.

Techniques for Drilling Hardened Steel

Drilling into hardened steel can be challenging due to its durability and resistance to cutting. To achieve a clean and precise hole, follow these essential steps:

- Choose the Right Drill Bit: High-Speed Steel (HSS) drill bits are ideal for hardened steel. Ensure they are sharp and coated for better performance.

- Use Proper Lubrication: Applying cutting oil11 reduces friction and heat, preventing the drill bit from dulling quickly.

- Secure the Workpiece: Clamping the steel firmly ensures stability and accuracy during drilling.

- Start with a Pilot Hole: Begin with a smaller drill bit to create a guide, making it easier for the larger bit to follow.

- Apply Steady Pressure: Use consistent pressure to maintain control and prevent the bit from slipping.

- Maintain Drill Speed: A moderate speed helps manage heat buildup and prolongs the life of your drill bit.

- Cool Down Periods: Allow the drill bit to cool between attempts to prevent overheating and material damage.

Table: Recommended Drill Bits for Hardened Steel

| Drill Bit Type | Material | Coating | Best Use |

|---|---|---|---|

| HSS Twist Drill Bit | High-Speed Steel | Titanium | General-purpose drilling |

| Cobalt Drill Bit | Cobalt Steel | N/A | Extreme hardness and durability |

| Carbide Drill Bit | Tungsten Carbide | N/A | High-precision and high-speed work |

| Diamond-Tipped Bit | Diamond-Coated | N/A | Ultra-hard materials |

By following these techniques and selecting the appropriate drill bit, you can efficiently drill holes in hardened steel with precision and minimal frustration.

How to Cut the Perfect Hole in Metal?

Struggling to achieve clean and precise holes in metal?

Cutting the perfect hole in metal requires the right tools, techniques, and attention to detail to ensure accuracy and quality.

Let me walk you through the steps to master metal hole cutting.

Steps to Achieve Perfect Holes in Metal

Creating flawless holes in metal involves a combination of the right equipment and meticulous execution. Here’s how to do it:

- Select the Appropriate Drill Bit: Use HSS or cobalt drill bits12 designed for metal to ensure effective cutting and longevity.

- Mark the Hole Location: Use a center punch to create a small indentation, preventing the drill bit from wandering.

- Secure the Metal Sheet: Clamp the metal firmly to avoid movement during drilling, ensuring precision.

- Start Slowly: Begin drilling at a low speed to establish a clear path, then gradually increase the speed.

- Use Cutting Fluid: Applying cutting oil lubricates the drill bit, reduces heat, and extends the bit’s life.

- Maintain Consistent Pressure: Apply steady pressure to keep the drill bit engaged without forcing it, preventing breakage.

- Clear Debris Regularly: Remove metal shavings frequently to maintain a clean cutting path and prevent clogging.

- Finish with a Deburring Tool: Smooth the edges of the hole to remove any roughness and achieve a professional finish.

H3: Tools Needed for Cutting Metal Holes

- Drill Press: Provides stability and precise control over drilling speed and pressure.

- Center Punch: Helps mark the exact spot for drilling, ensuring accuracy.

- Cutting Fluid: Essential for lubrication and cooling during the drilling process.

- Deburring Tool: Finishes the hole edges for a clean and smooth finish.

H3: Common Mistakes to Avoid

- Using Dull Drill Bits: A dull bit increases the risk of slipping and inaccurate holes.

- Applying Excessive Pressure: Too much force can break the drill bit or damage the metal.

- Neglecting Safety Precautions: Always wear protective gear to prevent injuries from metal shards and debris.

- Skipping Pilot Holes: Not starting with a smaller bit can lead to misaligned or oversized holes.

By adhering to these steps and avoiding common pitfalls, you can consistently cut perfect holes in metal, enhancing the quality and efficiency of your projects.

What HSS Drill Bit is Best for Metal?

Unsure which HSS drill bit will give you the best results on metal projects?

Choosing the best HSS drill bit for metal depends on the specific application, material hardness, and desired precision.

Let me help you find the perfect drill bit for your metalworking needs.

Selecting the Optimal HSS Drill Bit for Metal

High-Speed Steel (HSS) drill bits are a popular choice for metal due to their durability and heat resistance. Here’s how to select the best one for your projects:

- Material Compatibility: Ensure the HSS drill bit matches the type of metal you are working with. For harder metals like stainless steel, cobalt HSS bits are preferable.

- Coating Considerations: Coated HSS bits, such as titanium-coated, offer increased longevity and reduced friction, making them ideal for repetitive tasks.

- Point Angle: The point angle affects how the bit penetrates the metal. A standard 118-degree angle works well for general purposes, while a 135-degree angle is better for harder materials.

- Shank Type: Choose between standard or reduced shank types13 based on your drill’s chuck size and the flexibility you need.

- Bit Diameter and Length: Select the appropriate diameter and length for the hole size and depth required in your project.

- Quality and Brand: Opt for reputable brands known for manufacturing high-quality HSS drill bits to ensure reliability and performance.

Table: Top HSS Drill Bits for Metal

| Drill Bit Type | Material | Coating | Best For |

|---|---|---|---|

| Standard HSS Twist | High-Speed Steel | None | General-purpose metal drilling |

| Cobalt HSS Drill Bit | Cobalt Steel | None | Hardened metals like stainless steel |

| Titanium-Coated HSS | High-Speed Steel | Titanium | Extended life and reduced friction |

| Split Point Drill Bit | High-Speed Steel | None | Precision drilling with minimal walking |

| SDS HSS Drill Bit | High-Speed Steel | None | Heavy-duty drilling in metal |

H3: Benefits of Cobalt HSS Drill Bits

Cobalt HSS drill bits are infused with a percentage of cobalt, enhancing their heat resistance and durability. They are particularly effective for drilling into tough materials like stainless steel and cast iron. The added cobalt content allows these bits to maintain their hardness at higher temperatures, reducing wear and extending their lifespan.

H3: Choosing the Right Coating

Coatings on HSS drill bits, such as titanium nitride (TiN) or titanium carbonitride (TiCN), provide several advantages:

- Increased Durability: Coatings reduce wear and tear, allowing the bit to last longer.

- Reduced Friction: Lower friction levels help the bit cut more efficiently and stay cooler.

- Corrosion Resistance: Coatings can offer additional protection against rust and corrosion, especially important in humid or wet environments.

By carefully considering these factors, you can select the best HSS drill bit that meets your specific metalworking requirements, ensuring optimal performance and longevity.

What is the Best Way to Drill Stainless Steel?

Finding it tough to drill through stainless steel without damaging your tools?

Drilling stainless steel effectively requires the right approach, tools, and techniques to achieve clean and precise results.

Let me share the best practices to make your stainless steel drilling projects successful.

Best Practices for Drilling Stainless Steel

Stainless steel is known for its strength and resistance to corrosion, which makes drilling it a bit more challenging. Here’s how to do it right:

- Choose the Right Drill Bit: Use cobalt or titanium-coated HSS drill bits designed specifically for stainless steel to ensure durability and efficiency.

- Mark the Drilling Spot: Use a center punch to create a small dent, preventing the drill bit from wandering.

- Secure the Workpiece: Clamp the stainless steel firmly to avoid movement, ensuring accurate drilling.

- Apply Cutting Fluid: Lubricate the drilling area with cutting oil to reduce heat buildup and extend the drill bit’s life.

- Start with a Pilot Hole: Begin with a smaller drill bit to guide the larger bit, ensuring precision.

- Maintain Proper Drill Speed: Use a lower speed to prevent overheating, which can dull the drill bit and affect the metal’s integrity.

- Use Steady Pressure: Apply consistent, moderate pressure to keep the drill bit engaged without forcing it, preventing breakage.

- Clear Debris Regularly: Remove metal shavings frequently to maintain a clean cutting path and reduce friction.

- Finish with Deburring: Smooth the edges of the hole with a deburring tool14 for a professional finish.

Table: Recommended Drill Bits for Stainless Steel

| Drill Bit Type | Material | Coating | Best For |

|---|---|---|---|

| Cobalt HSS Drill Bit | Cobalt Steel | None | Drilling into hardened stainless steel |

| Titanium-Coated HSS | High-Speed Steel | Titanium | Enhanced durability and reduced friction |

| Step Drill Bit | High-Speed Steel | None | Creating precise and clean holes in thin stainless steel |

| Split Point Drill Bit | High-Speed Steel | None | Minimizing walking and ensuring accurate starts |

| Carbide Drill Bit | Tungsten Carbide | None | High-precision drilling in thick stainless steel |

H3: Importance of Proper Cooling

Maintaining the right temperature is crucial when drilling stainless steel. Excessive heat can cause the drill bit to lose its hardness, leading to premature wear and breakage. Using cutting fluid not only lubricates the drill bit but also helps dissipate heat, ensuring a longer tool life and a cleaner hole.

H3: Drilling Techniques for Optimal Results

- Use a Drill Press: A drill press provides better control over speed and pressure compared to a handheld drill, resulting in more accurate and consistent holes.

- Incremental Drilling: Gradually increase the drill bit size, stepping up to the desired diameter to reduce stress on the bit and the material.

- Avoid Overheating: Take breaks if necessary to allow the drill bit to cool, preventing overheating and potential damage to both the tool and the stainless steel.

By following these best practices, you can effectively drill stainless steel, achieving precise and clean holes while prolonging the life of your drill bits and maintaining the quality of your workpieces.

How do I Know What Kind of Drill Bit I Need?

Confused about selecting the right drill bit for your specific project?

Identifying the correct drill bit involves understanding your material, the hole size, and the desired finish to ensure optimal performance and results.

Let me help you navigate through the selection process to find the perfect drill bit for your needs.

How to Determine the Right Drill Bit for Your Project

Choosing the appropriate drill bit is essential for achieving the best results in any drilling task. Here’s how to determine the right one:

- Identify the Material: Different materials require different drill bits. Metals like stainless steel need HSS or cobalt bits, while wood can be drilled with brad or spade bits.

- Determine the Hole Size: Select a drill bit that matches the diameter of the hole you need. Use a drill bit gauge if necessary to ensure accuracy.

- Consider the Drill Bit Type: Various types include twist bits, spade bits, hole saws, and more. Each type is suited for specific applications.

- Check the Shank Size: Ensure the shank fits your drill’s chuck. Common sizes are 1/4 inch, 3/8 inch, and 1/2 inch.

- Assess the Coating: Coatings15 like titanium or cobalt enhance durability and performance, especially for tough materials.

- Evaluate the Point Angle: The point angle affects how the bit penetrates the material. Standard angles are suitable for general use, while specialized angles are better for specific materials.

- Quality and Brand: Opt for reputable brands to ensure you’re getting a reliable and long-lasting drill bit.

Table: Drill Bit Types and Their Uses

| Drill Bit Type | Best For | Material Compatibility |

|---|---|---|

| Twist Drill Bit | General-purpose drilling | Wood, metal, plastic |

| Spade Bit | Large-diameter holes in wood | Softwoods |

| Forstner Bit | Clean, precise holes in wood | Hardwood, softwood |

| Hole Saw | Creating wide holes | Wood, metal, plastic (with appropriate teeth) |

| Step Drill Bit | Drilling multiple hole sizes | Sheet metal, plastic |

| Masonry Bit | Drilling into concrete, brick | Masonry |

| Auger Bit | Deep holes in wood | Softwoods |

| Cobalt Drill Bit | Hard metals like stainless steel | Cobalt steel, stainless steel |

H3: Factors to Consider When Selecting a Drill Bit

- Durability: Choose bits made from high-quality materials to ensure they withstand the demands of your project.

- Precision: For tasks requiring exact measurements, select drill bits with precise tolerances to maintain accuracy.

- Efficiency: Coated drill bits can reduce friction and heat, allowing for faster and more efficient drilling.

- Versatility: If you work with various materials, consider a set of drill bits that cover a range of sizes and types to accommodate different tasks.

H3: Common Mistakes to Avoid

- Using the Wrong Bit for the Material: Using a wood bit on metal can damage both the bit and the material, leading to poor results.

- Ignoring the Shank Size: A mismatched shank size can cause the bit to wobble or not fit into the drill chuck properly.

- Overlooking the Coating: Not considering the coating can result in reduced bit lifespan and increased frustration during drilling.

- Neglecting to Mark the Drilling Spot: Failing to mark accurately can lead to misaligned holes and wasted effort.

By carefully evaluating these factors and understanding the specific requirements of your project, you can confidently select the right drill bit that ensures efficiency, precision, and durability in your drilling tasks.

Conclusion

Choosing the right HSS drill bit factory ensures quality and reliability for your metalworking needs.

-

Drill bits are a fundamental tool in various industries. ↩

-

The term "advanced coatings" refers to a specific technology used to enhance drill bit performance. ↩

-

This link will help explore how innovation drives the development of industrial tools, aligning with Dormer Pramet’s commitment to staying at the forefront of the industry. ↩

-

"Cutting speeds" is a technical term related to how fast a drill bit can cut through materials without wearing out. ↩

-

This link will direct users to authoritative sources explaining what constitutes high-grade materials in manufacturing. ↩

-

Adding this link helps provide users with more detailed information on the advanced manufacturing techniques specifically used for drill bits. ↩

-

"Quality" is a central aspect of YG-1’s brand message, and linking this keyword allows users to learn about industry standards and techniques that ensure high-quality products. ↩

-

"manufacturing processes" refers to the production methods that ensure the reliability and quality of Greenfield’s drill bits. ↩

-

"Drill bits" is a key term related to the context of the article, and linking it to an external source that provides further details about advanced engineering techniques used in drill bit. ↩

-

Coatings are an important feature in drill bits that affect their longevity and cutting efficiency. ↩

-

Cutting oil is a critical part of the drilling process. ↩

-

Cobalt drill bits are known for their strength and ability to withstand high temperatures. ↩

-

is crucial for matching the drill bit to the chuck size and flexibility. ↩

-

After drilling stainless steel, deburring is crucial for a clean finish. ↩

-

Drill bit coatings like titanium and cobalt are important for performance, especially when drilling into tougher materials. ↩